Belt assembly line

An assembly line and belt technology, applied in the field of assembly line, can solve the problems of increased thermal friction in the contact area, easy to increase the belt wear degree, unfavorable belt heat dissipation, etc., so as to reduce the thermal wear degree, promote heat dissipation, and reduce the effect of thermal friction area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

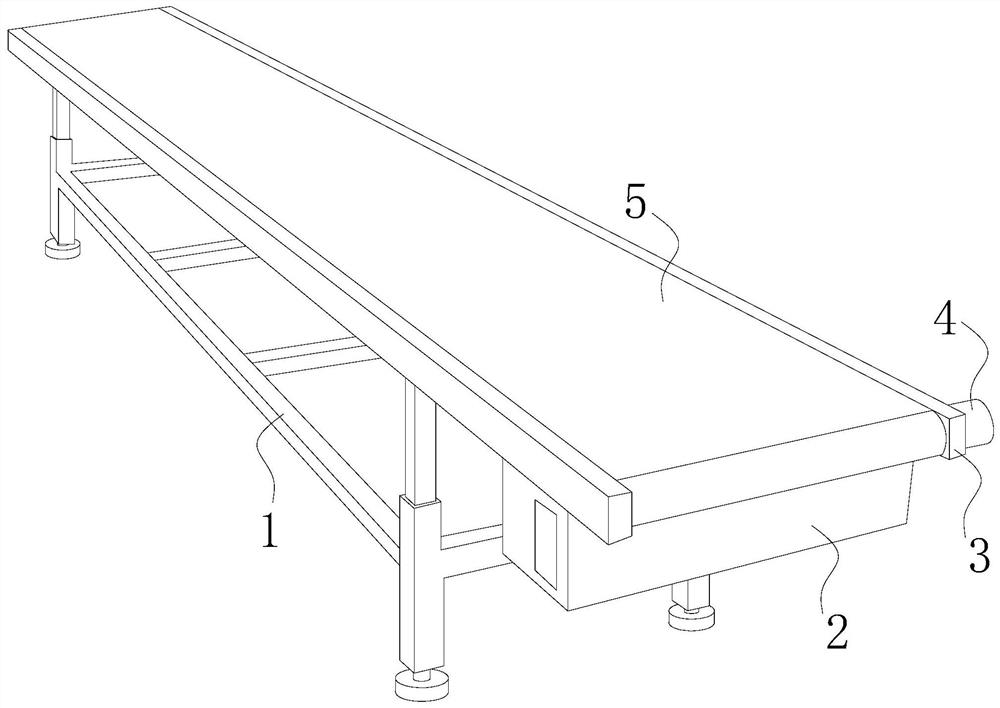

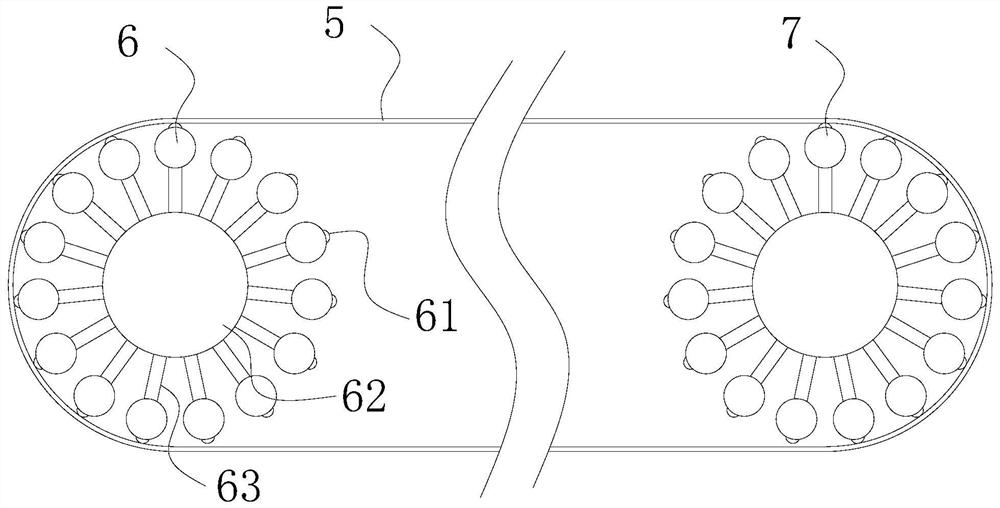

[0035] see Figure 1-4 , the present invention provides a belt assembly line technical solution: its structure includes a support frame 1, a control box 2, a limit guard 3, a motor 4, a belt 5, a first roller 6, a second roller 7, the support frame 1 Connect the limit guard plate 3, the limit guard plate 3 is provided with two pieces, a belt 5 is arranged between the two limit guard plates 3, one end of the belt 5 is movably matched with the first roller 6, and the other end is Matched with the second roller 7, the second roller 7 is connected to the motor 4, the motor 4 is connected to the limit guard plate 3, and the support frame 1 is also connected to the control box 2.

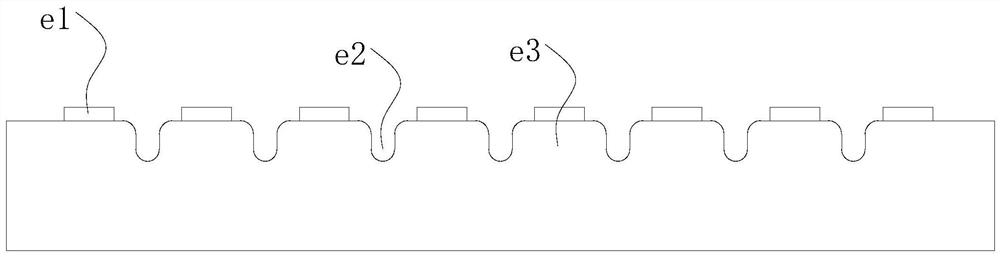

[0036] The first drum 6 includes a sub-cylinder 61, a central shaft 62, and a connecting plate 63. The fifteenth equal parts of the central shaft 62 are provided with connecting plates 63, and the connecting plate 63 is far away from the side of the central axis 62. Both of them are fixed with sub-cylind...

Embodiment 2

[0041] see Figure 1-9 , the present invention provides a belt assembly line technical solution: its structure includes a support frame 1, a control box 2, a limit guard 3, a motor 4, a belt 5, a first roller 6, a second roller 7, the support frame 1 Connect the limit guard plate 3, the limit guard plate 3 is provided with two pieces, a belt 5 is arranged between the two limit guard plates 3, one end of the belt 5 is movably matched with the first roller 6, and the other end is Matched with the second roller 7, the second roller 7 is connected to the motor 4, the motor 4 is connected to the limit guard plate 3, and the support frame 1 is also connected to the control box 2.

[0042] The first drum 6 includes a sub-cylinder 61, a central shaft 62, and a connecting plate 63. The fifteenth equal parts of the central shaft 62 are provided with connecting plates 63, and the connecting plate 63 is far away from the side of the central axis 62. Both are fixed with a sub-tube 61, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com