A kind of transportation equipment for processing mechanical parts

A technology of transportation equipment and mechanical parts, which is applied in the field of parts processing, can solve the problems of falling parts in the vehicle, damage of mechanical parts, shaking and bumping of the trolley, etc., and achieve the effect of convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

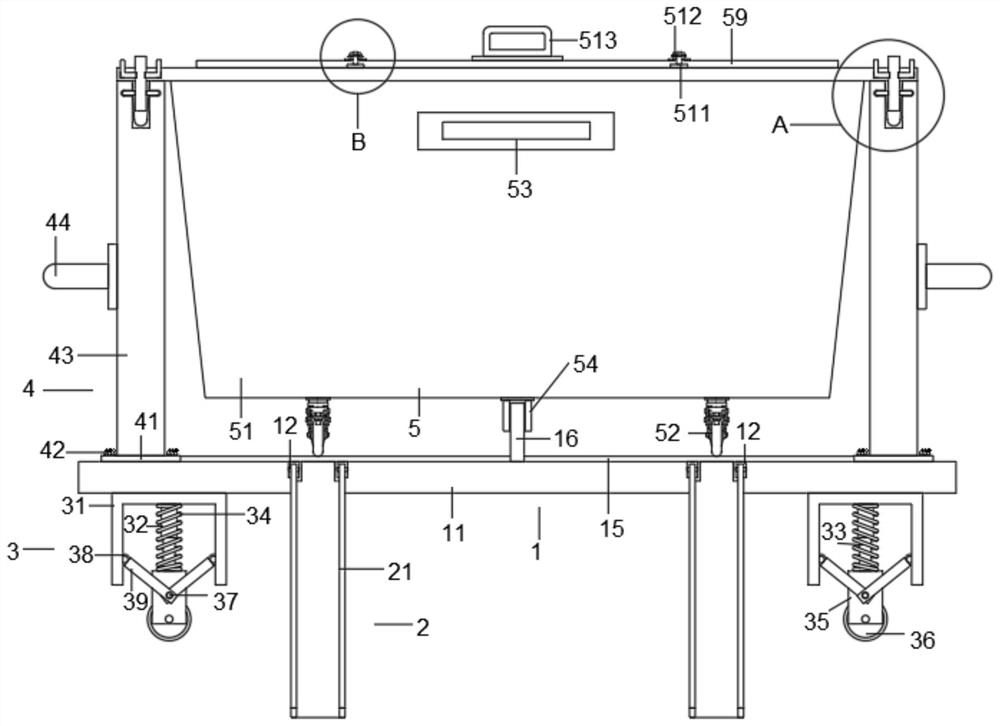

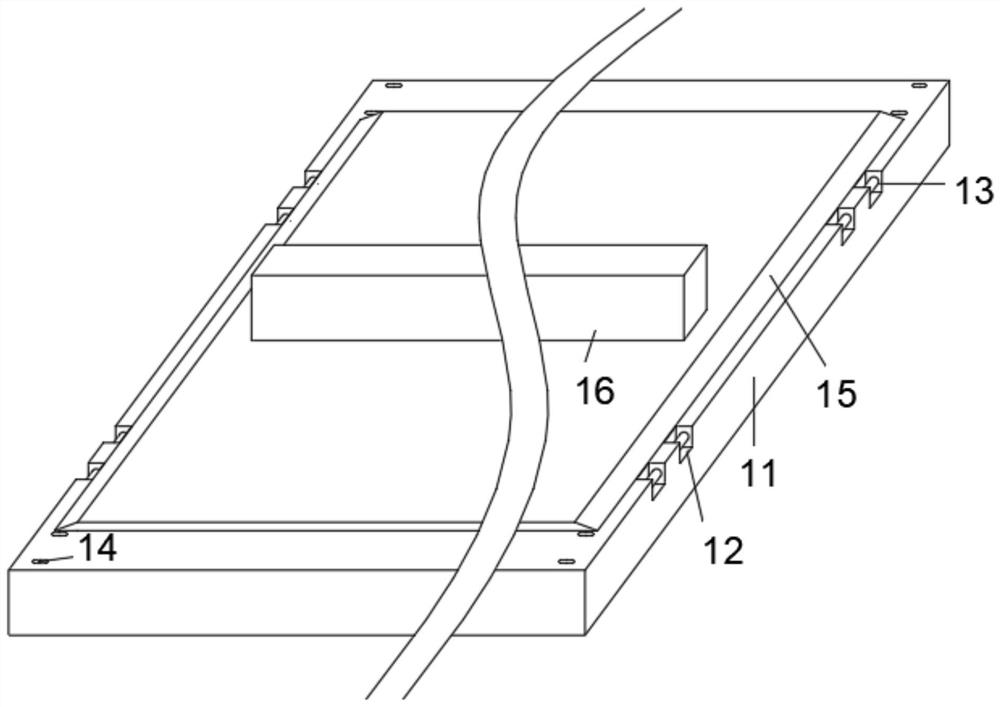

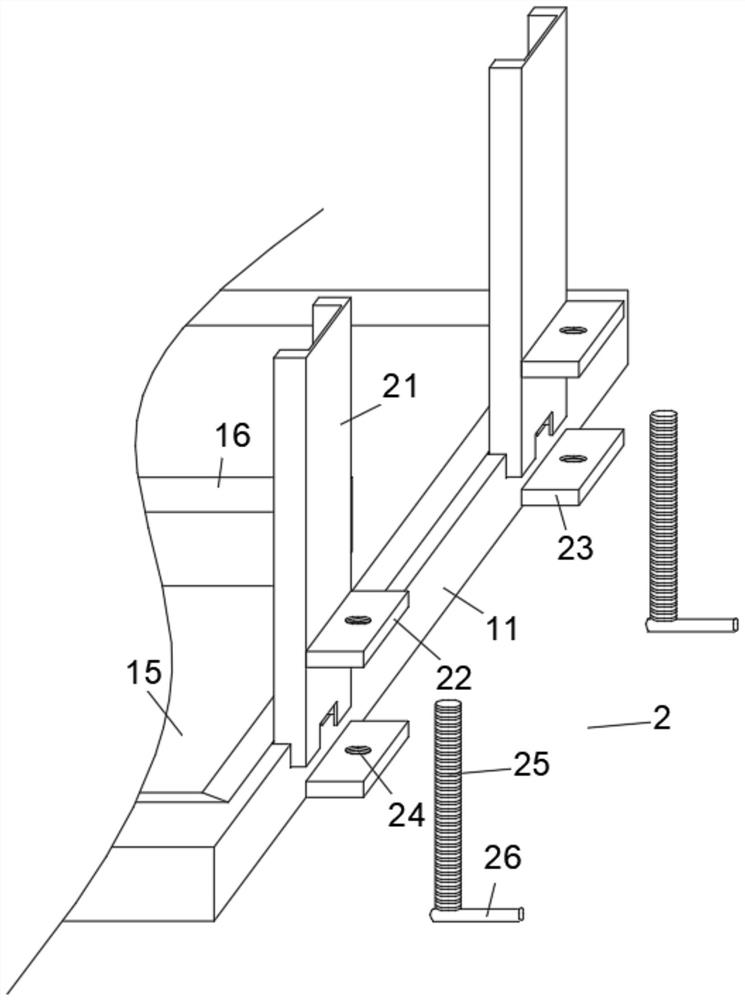

[0033] Such as Figure 1-10 As shown, this specific embodiment adopts the following technical solutions: a transportation device for processing mechanical parts, including a base mechanism 1, and the base mechanism 1 includes a fixed base 11, a movable groove 12, a movable rod 13, a threaded groove 14, and a rubber pad 15 and a fixed insert 16, the two sides of the front and rear ends of the top of the fixed base 11 are all excavated with movable grooves 12, and the inner walls on both sides of each of the movable grooves 12 are respectively fixedly connected with the two ends of the movable rod 13, and the fixed The top of the base 11 is fixed with a rubber pad 15 between the four pairs of movable grooves 12, the fixed base 11 is located at the center of the fixed plug 16 and fixed with a fixed plug 16 longitudinally, and the top of the fixed base 11 is located at the two ends of the rubber pad 15 The four corners are all dug with screw grooves 14, and the fixed base 11 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com