Floating type heavy load platform

A heavy-duty platform and floating technology, applied to floating buildings, ships, etc., can solve the problems of complex assembly on site, unpublished module connection details, and insufficient modularization, so as to facilitate standardized production, simplify assembly methods, and modules high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

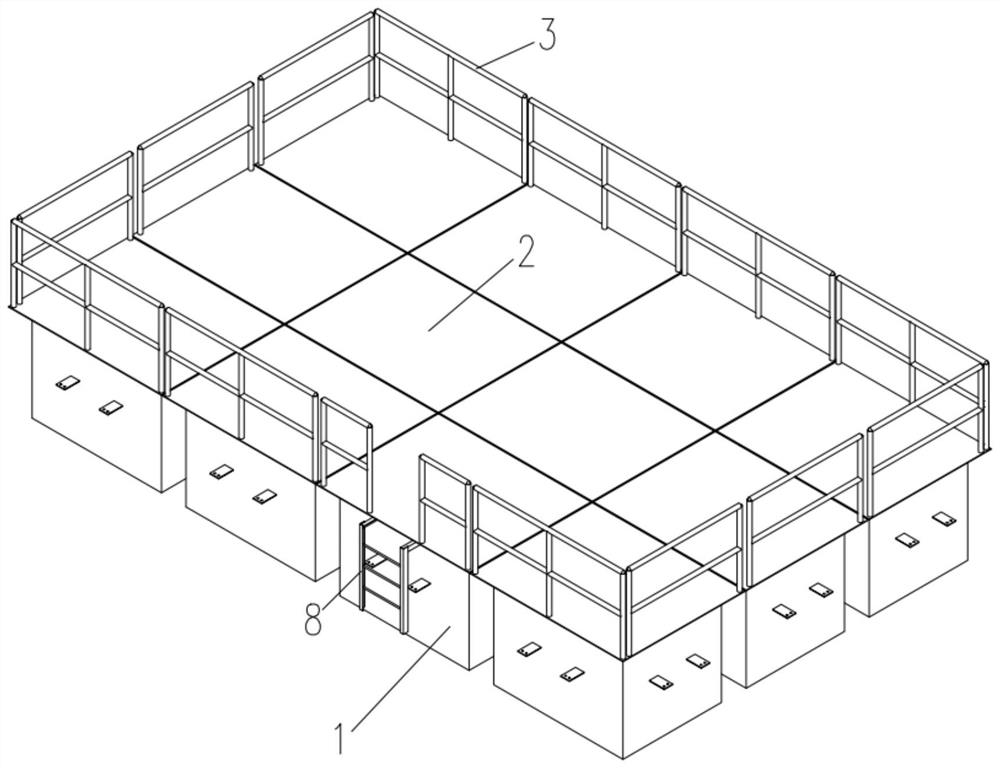

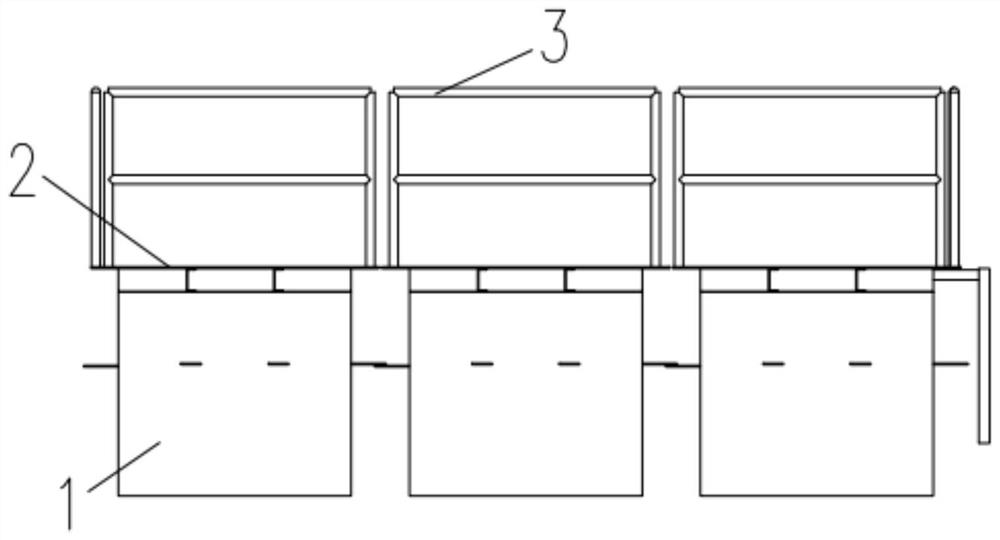

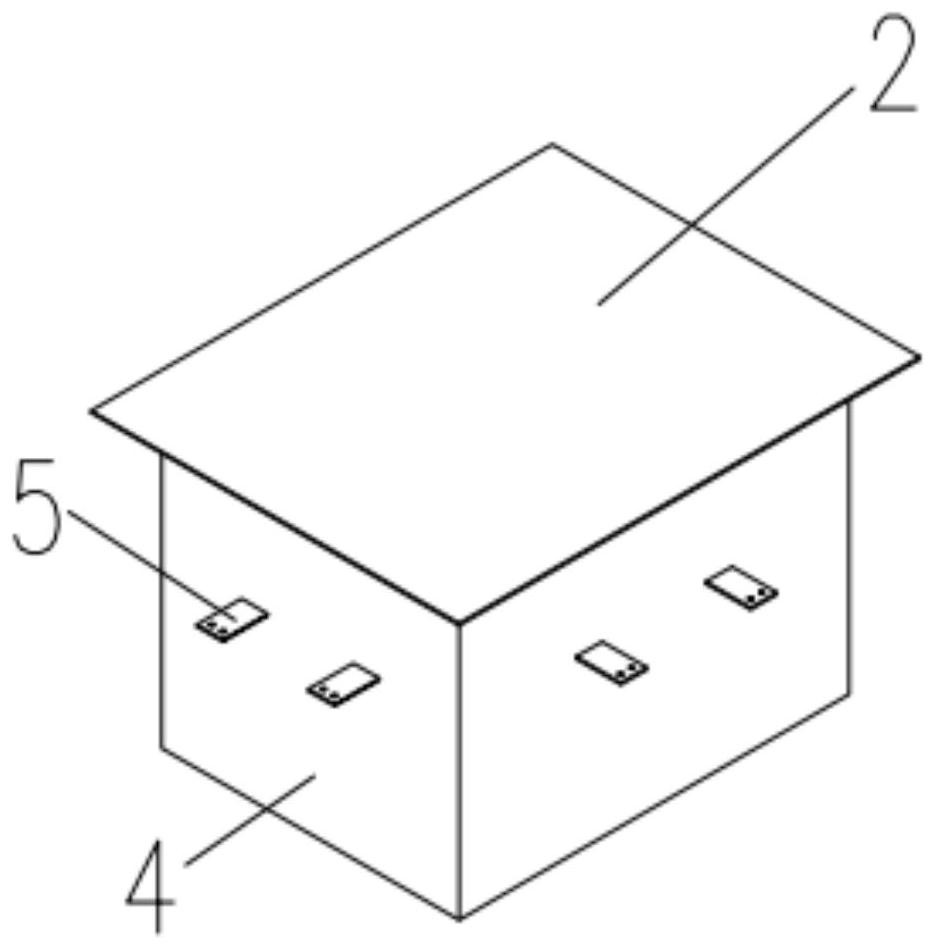

[0029] like Figure 1-4 As shown, a kind of floating heavy-duty platform of the present invention selects plasticity strong, light steel material as the main constituent material of floating heavy-duty platform, and this platform comprises a plurality of independent modular buoyant tanks 1 with exactly the same structure, module The buoyancy tanks 1 are spliced together; each modular buoyant tank 1 includes a buoyancy tank 4, frame beams 6 and deck 2, and stiffeners 7 are arranged on six surfaces in the buoyancy tank 4 (such as Image 6 ), to increase the rigidity of the six faces of the floating cabin 4; the four outer facades of the floating cabin 4 are provided with lugs 5, and the adjacent floating cabins 4 are connected by the lugs 5; The frame beam 6 is welded on the top surface of the floating cabin 4 to form an integral body with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com