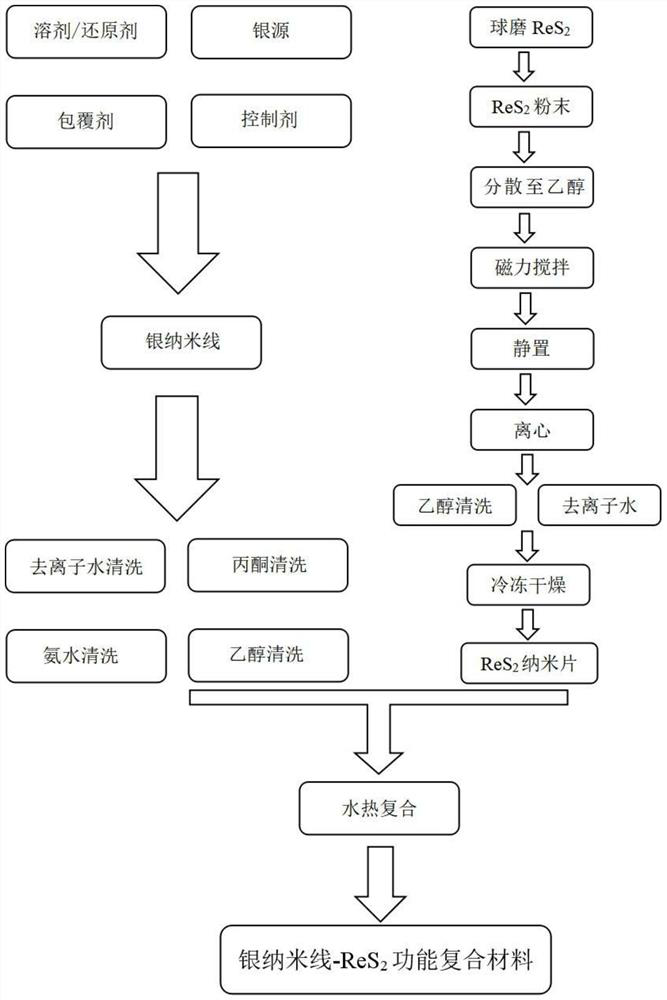

Silver nanoline-ReS2 functional composite material and preparation method thereof

A functional composite material, silver nanowire technology, applied in catalyst activation/preparation, nanotechnology, nanotechnology, etc., can solve the problems of insufficient stability, uneven Raman activity, poor controllability, etc., and achieve anti-oxidation. Strong ability, low cost, and the effect of improving SERS activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Step 1, preparing silver nanowires,

[0048] 1.1) Mix 120mL glycerol and 4.9g polyvinylpyrrolidone in a three-neck round bottom flask, and stir strongly at 90°C for 15min;

[0049] 1.2) When the temperature naturally drops to 40°C, add 7 mL of a glycerol solution containing 0.3 mL of water and 48 mg of sodium chloride to the flask, and stir for 8 minutes with a strong magnetic field;

[0050] 1.3) Then 1.21g of silver nitrate was quickly added to the solution, stirred gently (60rpm), and then the reaction temperature was raised from 40°C to 170°C within 40min;

[0051] 1.4) When the temperature reaches 170°C, stop heating, pour the solution in the flask into a 500mL beaker immediately, then add deionized water at a ratio of 1:1 to lower the temperature, leave it at room temperature for two days, and remove the supernatant , to obtain silver nanowire solution;

[0052] The reaction process of the whole step 1 is carried out under reflux conditions.

[0053] Step 2, pu...

Embodiment 2

[0064] Step 1, preparing silver nanowires,

[0065] 1.1) Mix 120mL of ethylene glycol and 4.9g of polyvinylpyrrolidone in a three-neck round bottom flask, and stir strongly at 90°C for 15min;

[0066] 1.2) When the temperature naturally drops to 60°C, add 0.7mL of water and 72mg of sodium chloride to the flask Ethylene glycol Solution 7mL, strong magnetic stirring 8min;

[0067] 1.3) Quickly add 1.21g of silver nitrate into the solution, stir gently (60rpm), then raise the reaction temperature from 60°C to 210°C within 50min;

[0068] 1.4) When the temperature reaches 210°C, stop heating, pour the solution in the flask into a 1000mL beaker immediately, then add deionized water at a ratio of 1:2 to lower the temperature, leave it at room temperature for two days, and remove the supernatant , to obtain silver nanowire solution;

[0069] The reaction process of the whole step 1 is carried out under reflux conditions.

[0070] Step 2, purifying silver nanowires,

[0071] The...

Embodiment 3

[0079] Step 1, preparing silver nanowires,

[0080] 1.1) Mix 150mL of glycerol and 5.14g of polyvinylpyrrolidone in a three-neck round bottom flask, and stir strongly at 100°C for 20min;

[0081] 1.2) When the temperature naturally drops to 50°C, add 7mL of a glycerol solution containing 1.2mL of water and 16mg of ferric chloride to the flask, and stir with a strong magnetic field for 8min;

[0082] 1.3) Then quickly add 1.21g of silver nitrate into the solution, stir gently (60rpm), then raise the reaction temperature from 50°C to 230°C within 40min;

[0083] 1.4) When the temperature reaches 230°C, stop heating, pour the solution in the flask into a 1000mL beaker immediately, then add deionized water at a ratio of 1:3 to lower the temperature, leave it at room temperature for two days, and remove the supernatant , to obtain silver nanowire solution;

[0084] The reaction process of the whole step 1 is carried out under reflux conditions.

[0085] Step 2, purifying silver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com