Extraction tank for plant extraction

A plant extraction and extraction tank technology, which is applied in solvent extraction, solid solvent extraction, chemical instruments and methods, etc., can solve the problems of lower extraction speed, low extraction efficiency of extraction tank, and slow separation speed of extraction liquid and residue, etc., to achieve Improve the extraction efficiency and effect, improve the heat utilization rate and heat transfer efficiency, improve the effect of heat exchange efficiency and stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

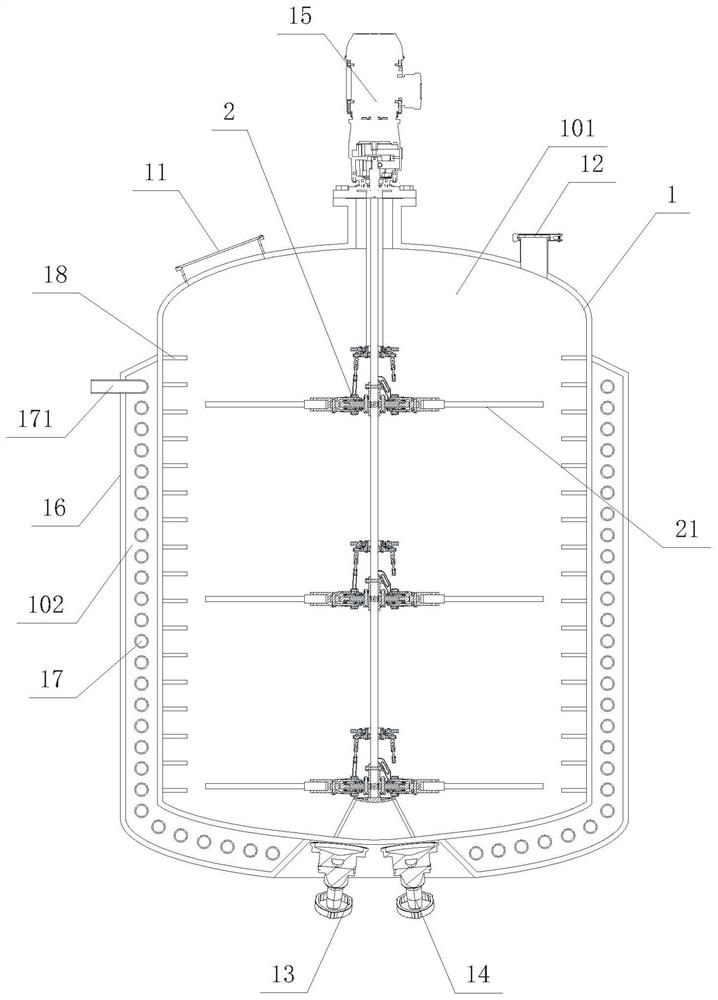

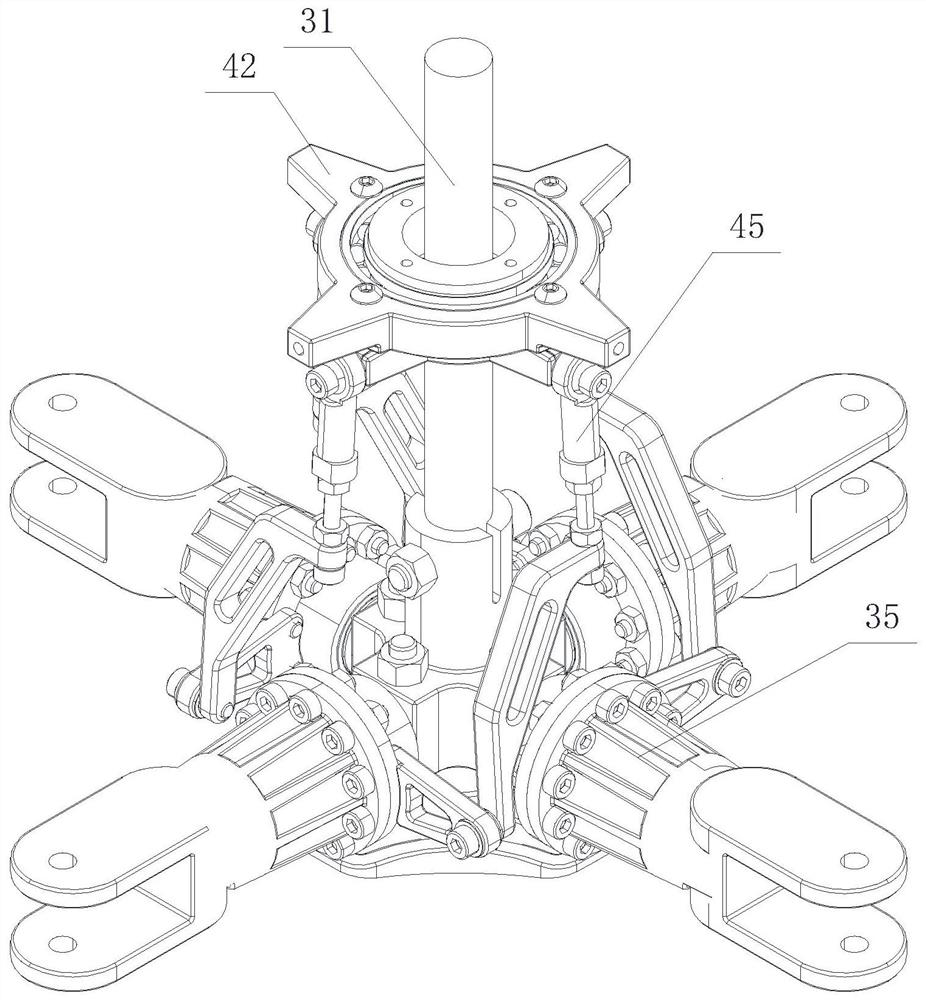

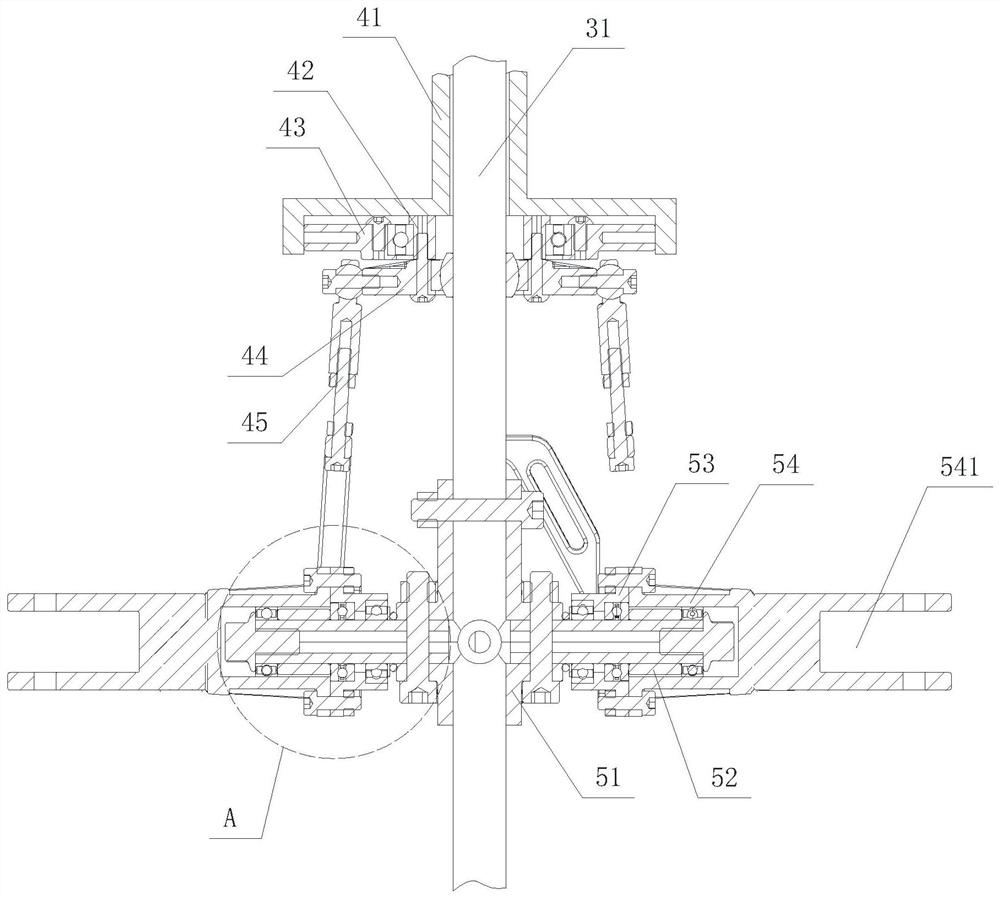

[0024] refer to Figure 1 to Figure 5 , the present invention provides an extraction tank for plant extraction, for the extraction of plant components, specifically, it includes a tank body 1, the tank body is made of stainless steel, and the whole is a vertically arranged cylindrical structure. An inner chamber for containing and reacting is formed in the tank body, a pressure gauge and a thermometer are arranged in the inner chamber, a heavy liquid inlet 11 and a light liquid outlet 12 are arranged on the top of the tank body, and a The heavy liquid outlet 13 and the light liquid inlet 14 are rotatably installed with a rotating shaft 31 in the tank body. The rotating shaft 31 is coaxially arranged with the tank body, and a support seat is arranged at the bottom center of the cavity. On the support base, paddles 21 are arranged on the side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com