Aerator for crayfish farming

A kind of technology of aeration machine and lobster, which is applied in application, fish farming, cleaning method and utensils, etc. It can solve the problems of difficulty in moving the position of the device, large output force, obstruction of cleaning work, etc., and achieves enhanced convenience and practical value , increase the buffering and shock absorption capacity, and ensure the effect of transmission operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

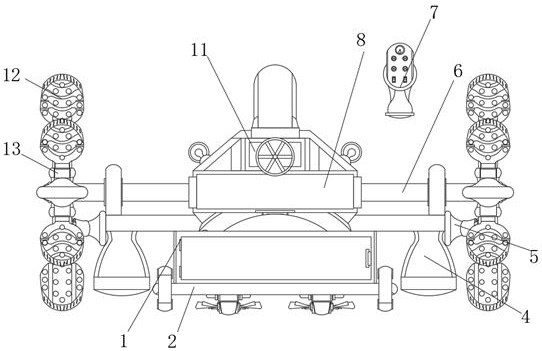

[0031] Example 1, such as Figure 1-5 As shown, during the period when the impeller 13 drives the blade 12, it will automatically brush through the position of the cleaning brush 5, so as to prevent the aquatic weed impurities adhered to the blade 12 from flowing into the transmission gap between the impeller 13 and the transmission shaft 6 to be entangled, increasing the device's Self-cleaning function enhances the convenience of follow-up cleaning work.

Embodiment 2

[0032] Example 2, such as Figure 6-7As shown, when the device needs to be moved, the high-pressure air flow can be introduced into the sealing groove 114 by starting the high-pressure blower 11. At this time, the gas will flow into the four groups of injection pipes 113 under the guidance of the hemispherical air guide block 112, and With the helical cooperation of the helical pattern 115 to strengthen the output force after the gas injection, four groups of injection gas can be used to promote the device to have a thrust, which can slowly move on the water surface, so as to adjust the installation position of the device, and at the same time, the operator The pull rope connected with the device can be pulled to perform secondary output, which facilitates the movement of the control device and increases the convenience and practicality of the device.

[0033] Working principle: when the device is in use, first put the device into the breeding water surface, then start the ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com