Helium medium valve sealing performance test device and test method thereof

A test device and valve sealing technology, which are used in fluid tightness testing, measuring devices, and liquid tightness measurement using liquid/vacuum degree. and other problems, to achieve the effect of saving economic costs, convenient and accurate measurement, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in further detail below in conjunction with accompanying drawing.

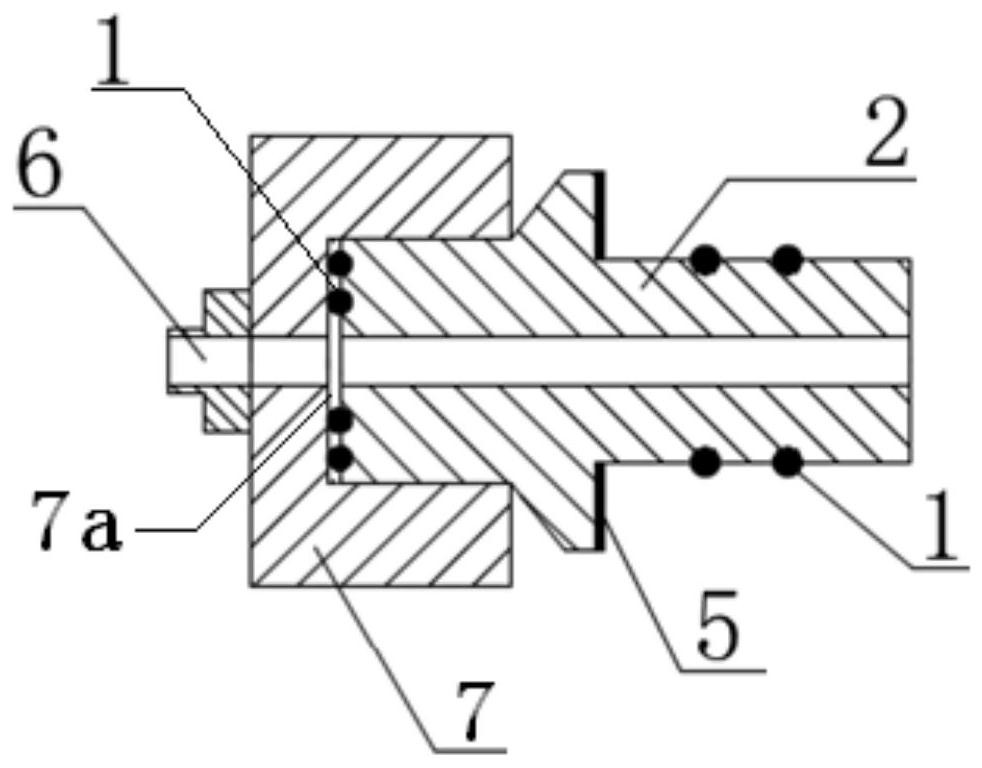

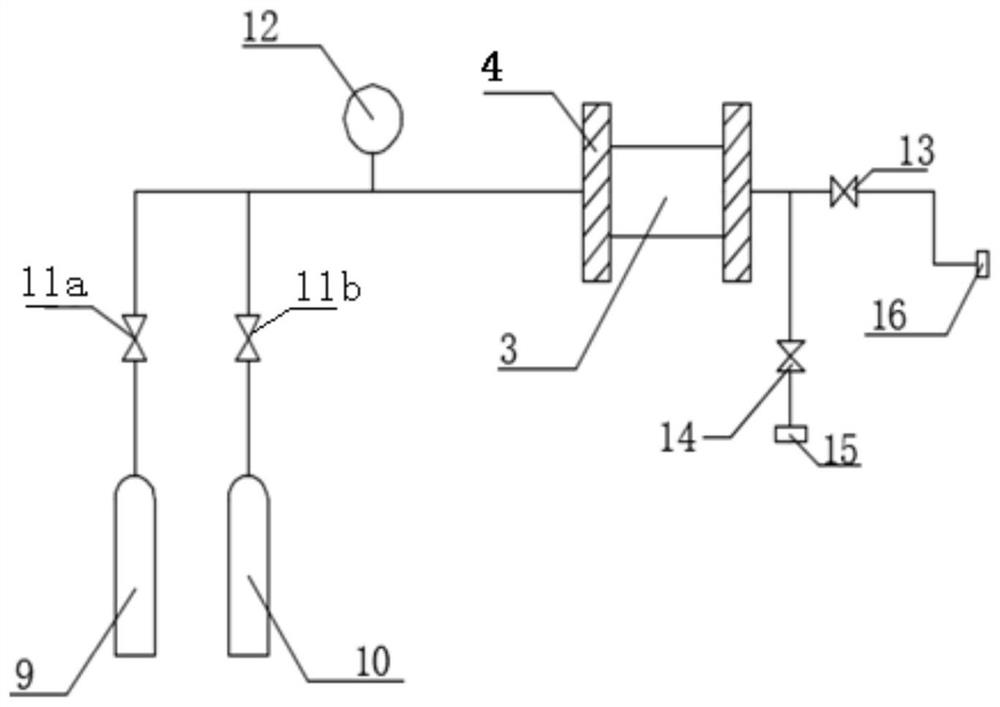

[0043] see image 3 , a helium medium valve sealing performance test device, comprising a high-pressure helium cylinder 9 and a high-pressure nitrogen cylinder 10, the outlet end of the high-pressure helium cylinder 9 is connected to the inlet end of the first needle-type regulating valve 11a through a pipeline, and the high-pressure nitrogen cylinder The outlet port of 10 is connected to the inlet port of the second needle regulating valve 11b through a pipeline, and the outlet port of the first needle regulating valve 11a and the outlet port of the second needle regulating valve 11b are connected to the inlet of the fixture 4 after the pipeline merges. end, the gas outlet pipeline of the fixture 4 is divided into two branches, one of which is connected to the inlet port of the detection valve 14, the gas outlet port of the detection valve 14 is connected to the detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com