Method of treating rock piles by surface grouting and vibratory compacting

A technology of vibratory compaction and rock piles, which is applied to roads, road repairs, roads, etc., can solve the problems of large voids in rock piles, uncontrollable grouting volume, and large grouting volume, so as to reduce foundation voids and improve Bearing capacity and modulus of resilience, effect of low filling and grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

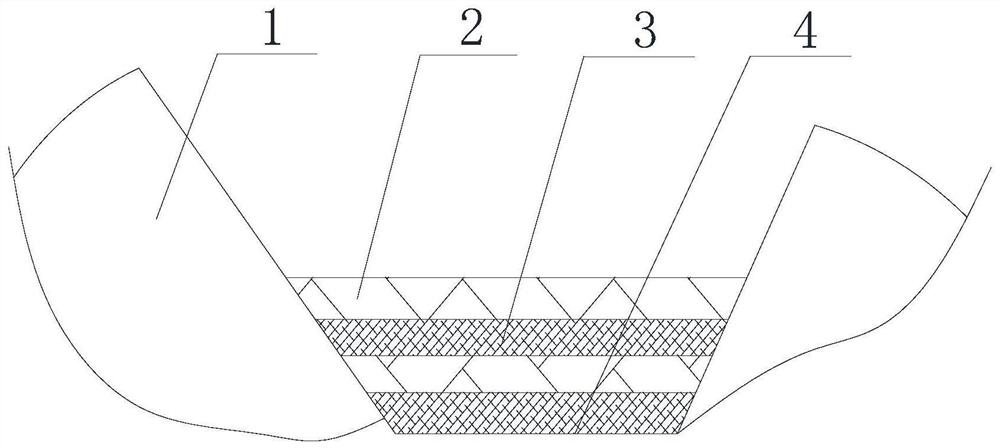

[0030] Such as figure 1 , figure 2 Shown, a kind of surface grouting vibratory compaction method for processing rock piles, comprises the following steps:

[0031] S1. Excavate a piece of crushed stone within the range of depth to be treated within the scope of the roadbed 4, place the roadbed 4 between multiple rock piles 1, and pile the excavated pieces of crushed stone on the rock pile 1 near the roadbed 4 to facilitate backfilling gravel;

[0032] S2. Subgrade 4 is gradually filled in layers from bottom to top:

[0033] S21. Perform surface pressureless grouting and vibratory compaction in sequence to form a grouting layer 3. The grouting material 5 used for surface pressureless grouting is cement mortar or cement slurry, and the water-cement ratio of the grouting material 5 is 0.5;

[0034] S22, backfilling pieces of gravel on the grouting layer 3 to form the rock filling layer 2;

[0035] S23, repeating steps S21 and S22, until the filling is completed;

[0036] Wh...

Embodiment 2

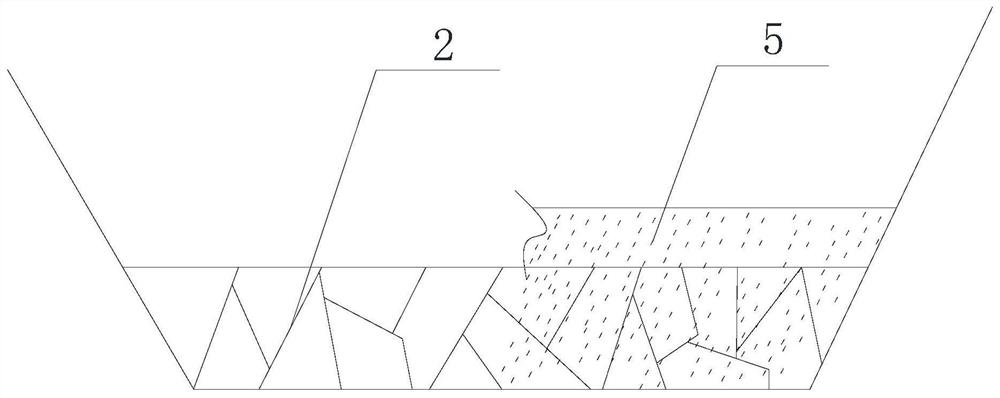

[0039] Such as figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1. When the surface is grouted without pressure, the grouting material 5 is directly poured on the surface of the rock filling layer 2, and the grouting material 5 fills the gaps between the broken stones in the rock filling layer 2 under the action of gravity.

Embodiment 3

[0041] Such as figure 1 , figure 2 As shown, this embodiment is based on embodiment 1 or embodiment 2, and the top of the rock filling layer 2 in step S22 is flake gravel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com