Anti-tipping control method for high-altitude hoisting

A control method and anti-overturning technology, applied in the field of control, can solve problems such as danger and yaw difference of hoisted objects, and achieve the effects of low cost, comprehensive control and reduction of yaw amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The technical scheme of the present invention will be further described below in conjunction with the drawings.

[0038]The crane in this embodiment is an all-terrain crane with a maximum hoisting height of 155m. It should be noted that other high-altitude hoisting cranes such as tower cranes and crawler cranes have similar working principles, or that the hoisting height is greater than or less than the maximum value, which does not constitute the restriction of the anti-tipping function of the high-altitude hoisting.

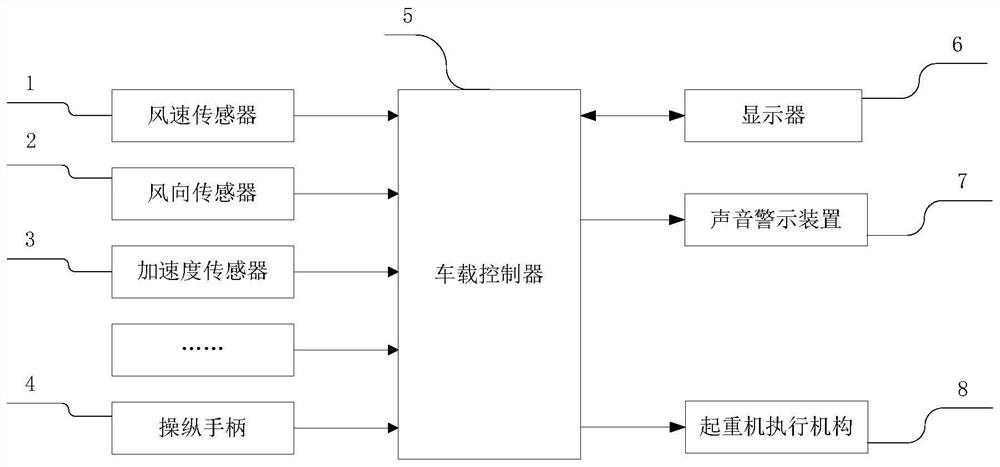

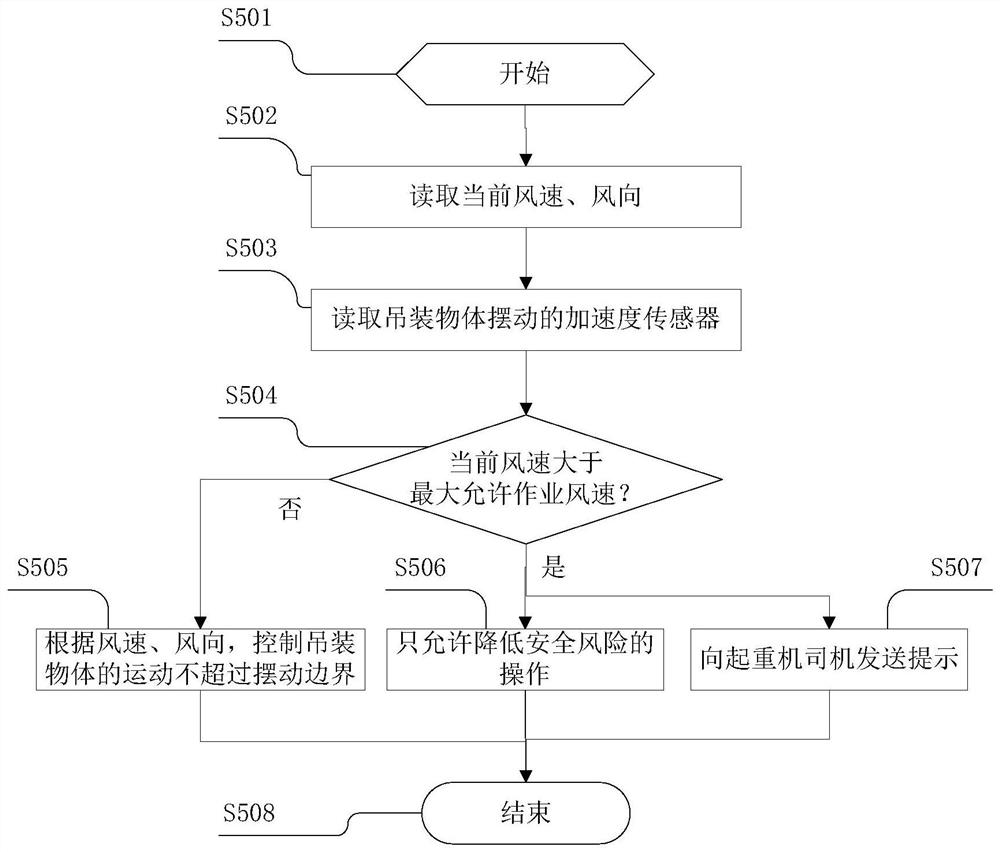

[0039]Such asfigure 1 As shown, the present invention provides a structural diagram of the high-altitude hoisting anti-tilt control system of the embodiment. The crane on-board computer detects the wind speed and wind direction of the high-altitude hoisting, and judges that the current wind speed is not greater than the maximum allowable operating wind speed combined with the driver’s operation input and the current crane Attitude parameters, dynamically plan and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com