Cloth unfolding and hanging device for spinning

A suspension device and fabric technology, applied in the textile field, can solve problems such as fabric loosening and falling off, unwinding cannot match the movement of the clamping part, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

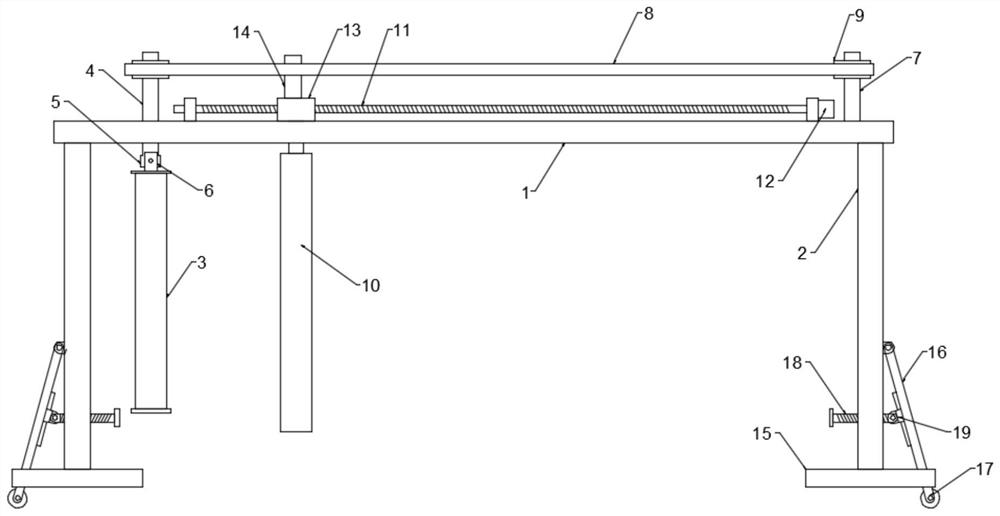

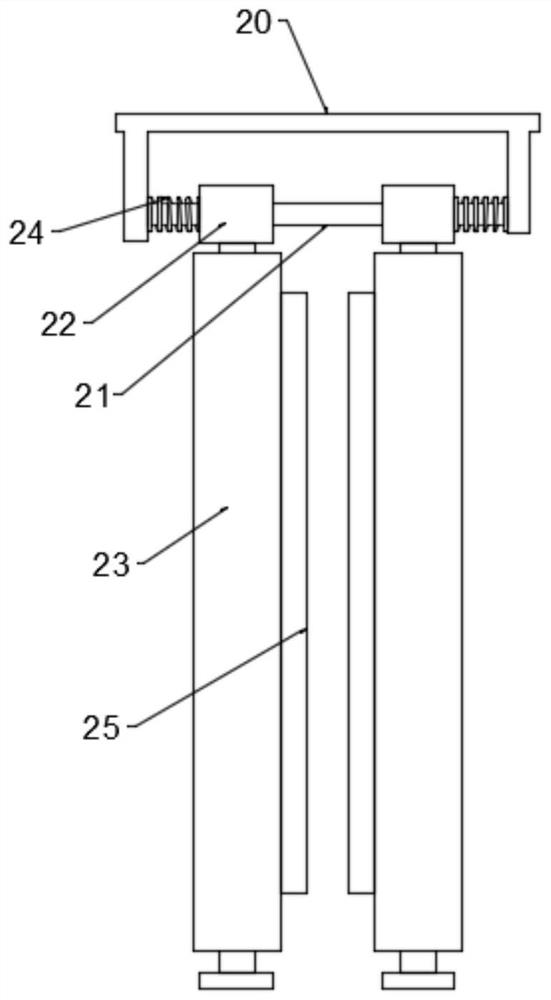

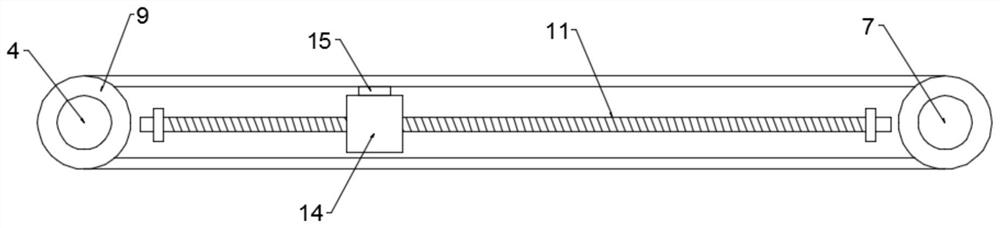

Embodiment 1

[0022] see Figure 1~3 , in the embodiment of the present invention, a kind of weaving fabric unfolding suspension device, comprises upper horizontal frame 1 and two side brackets 2 arranged on the end of upper horizontal frame 1, each side bracket 2 bottom is all provided with side connecting rod 15 , the two ends of the upper horizontal frame 1 are also respectively provided with an upper rotating rod shaft 4 and a transmission rod shaft 7 which are rotatably connected thereto. Both the top end of the rotating rod shaft 4 and the transmission rod shaft 7 are provided with a connecting pulley 9, and the two connecting pulleys 9 are connected by a driving belt 8 around the transmission connection. The top rotatably connected push screw 11, the push screw 11 is provided with a spiral sliding seat 13 whose bottom slides on the upper end surface of the upper horizontal frame 1 and spirally cooperates with the push screw 11, the upper end of the spiral slide 13 An upper ejector r...

Embodiment 2

[0027] The difference between the embodiment of the present invention and embodiment 1 is: the bottom of each side bracket 2 is provided with a lower bracket 16 and the bottom end of the lower bracket 16 is provided with a moving roller 17, and the setting of the moving roller 17 is convenient for the movement of the whole device. The top end of the lower bracket 16 is hinged with the side wall of the side bracket 2, and the lower bracket 16 is also provided with a mounting slide seat 19 that slides along the rod length direction through the guide rail on the lower bracket 16. There is an adjusting screw 18 matched with the bolt, the end of the adjusting screw 18 is a rotating structure and is hinged with the side of the installation slide 19; then the adjusting screw 18 is screwed to make the lower bracket 16 Rotate around its top to adjust its inclination angle, so that the moving roller 17 can break away from or touch the ground, and the moving roller 17 can break away from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com