Tool bit component of electric shaver

An electric shaver and cutter head assembly technology, which is applied in the direction of metal processing, etc., can solve the problems of hair being easily pushed against the skin, unable to be introduced into the cutter net, and hair stuck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

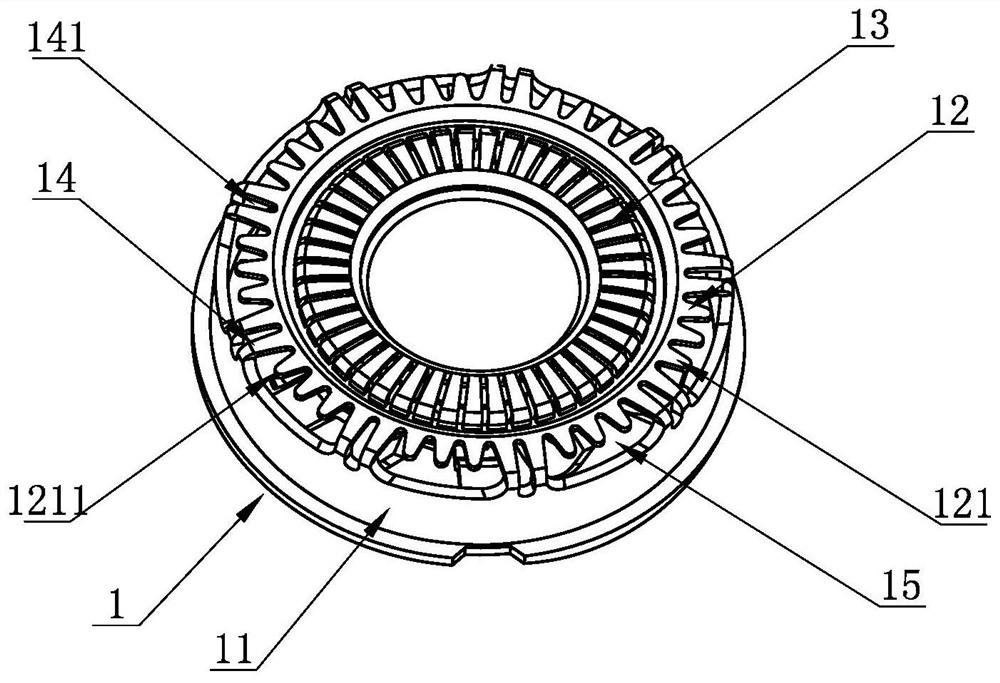

[0028] Such as Figure 1-9 As shown, a cutter head assembly of an electric shaver includes a net cover 1 and a knife holder 2, wherein the net cover 1 includes a support ring 11, an outer knife net 12, an inner knife net 13, an inner knife net 13, The outer knife net 12, the support ring 11 and the knife rest 2 are all arranged coaxially. The position corresponding to the outer knife net 12 on the knife rest 2 is provided with an outer blade 21. The position corresponding to the inner knife net 13 is provided with an inner blade 22 on the knife rest 2. The blade 21 and the outer knife net 12 can cooperate with each other for cutting, and the inner blade 22 and the inner knife net 13 can cooperate with each other for cutting. The quantity of the outer blade 21 and the inner blade 22 can be set voluntarily as required. To elaborate again, the inner circle of the outer knife net 12 is connected with the outer circle of the inner knife net 13. In the specific embodiment of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com