Black tea fermentation production method and device

The technology of a fermentation device and a fermentation method is applied in the field of black tea fermentation methods and devices, and can solve the problems of inability to ensure simultaneous rolling and discharging, high labor costs, and waste of time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

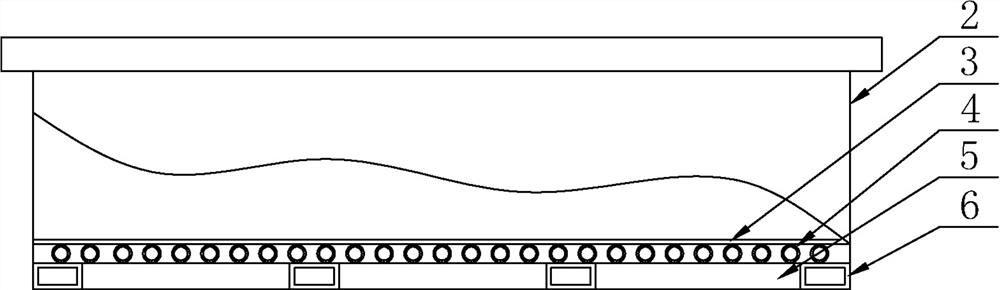

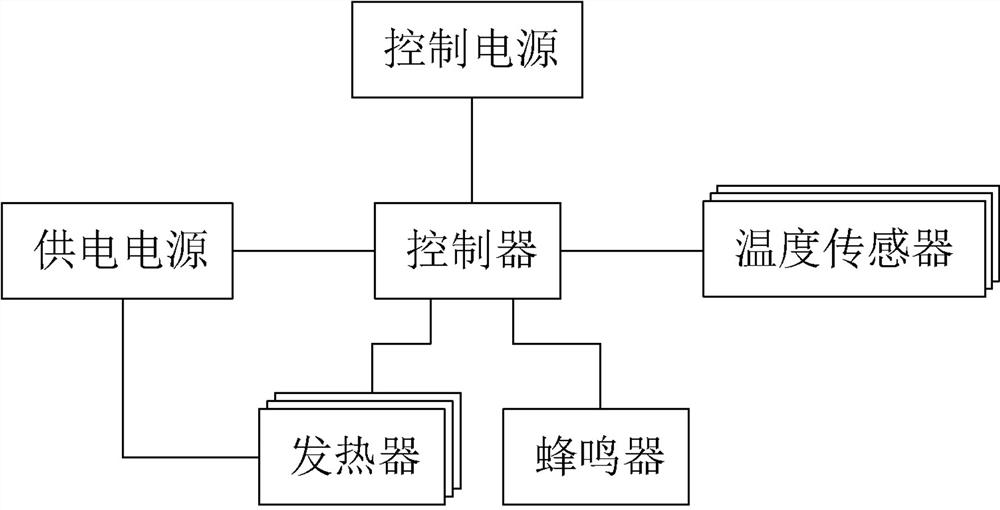

[0036] Depend on Figure 1 to Figure 3It can be seen that a black tea fermentation device includes a frame body 1, and the frame body 1 is a layered structure, and each layer of the frame body 1 is respectively equipped with a tea base fermentation tank 2, and the upper and lower sides of the frame body 1 are adjacent to each other. There is a gap for air circulation between the two tea dhool fermentation tanks 2, so as to supply tea dhool with enough oxygen, which is beneficial to the oxidation and fermentation of black tea dhool; Heating mechanism; the heating mechanism includes a controller arranged on the frame body 1, and the controller is respectively connected with a control power supply, a power supply, a temperature sensor, and a buzzer; the bottom of the tea dregs fermentation tank 2 is provided with a heater 4. The heater 4 is connected with the controller.

[0037] The bottom of the tea dhool fermentation tank 2 of the present invention is respectively provided wi...

Embodiment 2

[0054] The gap described in the black tea fermenting device in this embodiment is 9 cm to 11 cm (10 cm in this embodiment).

[0055] A black tea fermentation method, it comprises the following steps:

[0056] ⑴ Withering and twisting: Fresh tea leaves with one bud and two leaves and one bud and three leaves on the day of picking are used as raw materials, and placed in a clean and ventilated environment to wither. Fold continuously, when the water content drops to 60%~65% (65% in this embodiment), it is moderately withered; then knead for 90~120 minutes (120 minutes in this embodiment) until the leaf cell broken rate reaches more than 85% ;

[0057] (2) One-stage fermentation: place a black tea fermentation device in a clean and ventilated fermentation room, spread the rolled tea leaves evenly in the tea base fermentation tank 2 of the black tea fermentation device, and cover the tea leaves with a wet cloth, and set the fermentation temperature to 30°C~ Ferment at 32°C (32°C...

Embodiment 3

[0066] The gap described in the black tea fermenting device in this embodiment is 9 cm to 11 cm (11 cm in this embodiment).

[0067] A black tea fermentation method, it comprises the following steps:

[0068] ⑴ Withering and twisting: Fresh tea leaves with one bud and two leaves and one bud and three leaves on the day of picking are used as raw materials, and placed in a clean and ventilated environment to wither. Fold continuously, when the water content drops to 60%~65% (63% in this embodiment), it is moderately withered; then knead for 90~120 minutes (100 minutes in this embodiment) until the leaf cell broken rate reaches more than 85% ;

[0069] (2) One-stage fermentation: place a black tea fermentation device in a clean and ventilated fermentation room, spread the rolled tea leaves evenly in the tea base fermentation tank 2 of the black tea fermentation device, and cover the tea leaves with a wet cloth, and set the fermentation temperature to 30°C~ Ferment at 32°C (30°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com