An over-pcb board connector capable of observing and verifying the annular gap on the back

A PCB board and ring gap technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve problems such as image acquisition obstacles, safety hazards, and unstable electrical connections, and achieve improved connection stability and fast Effect of machine inspection and reduction of metal material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

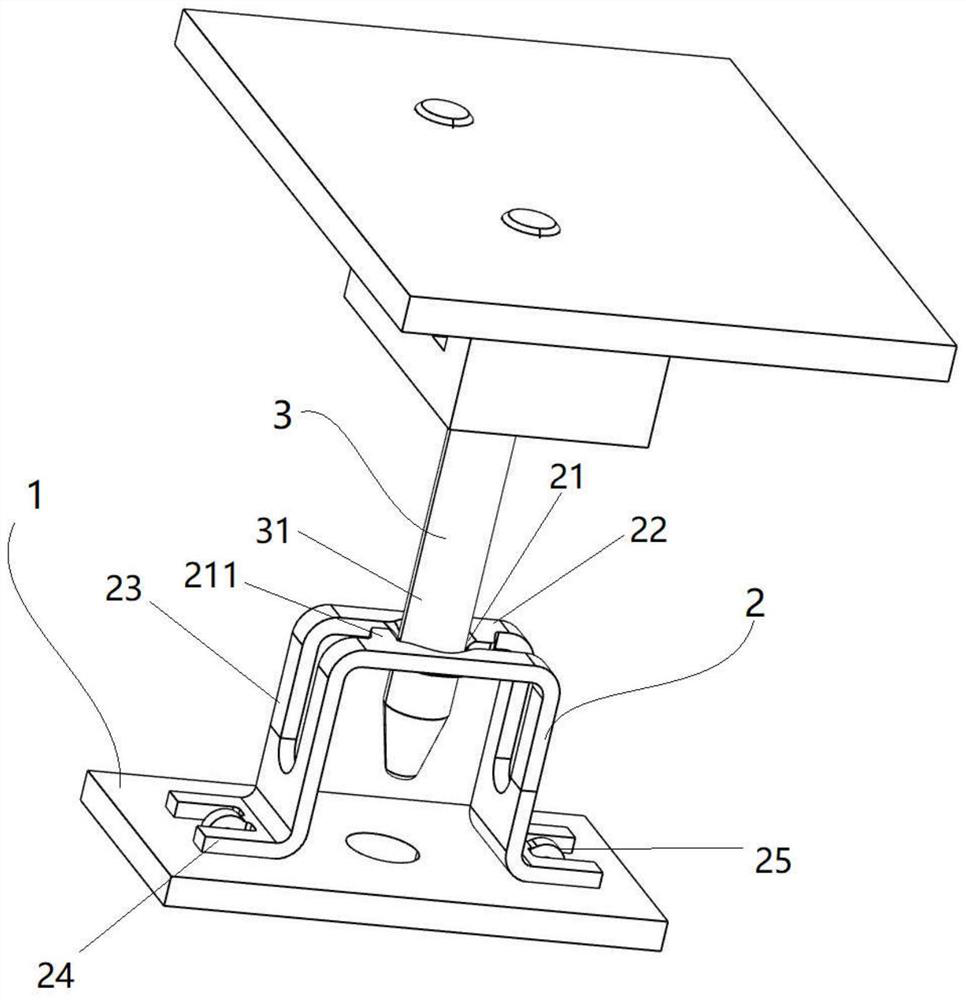

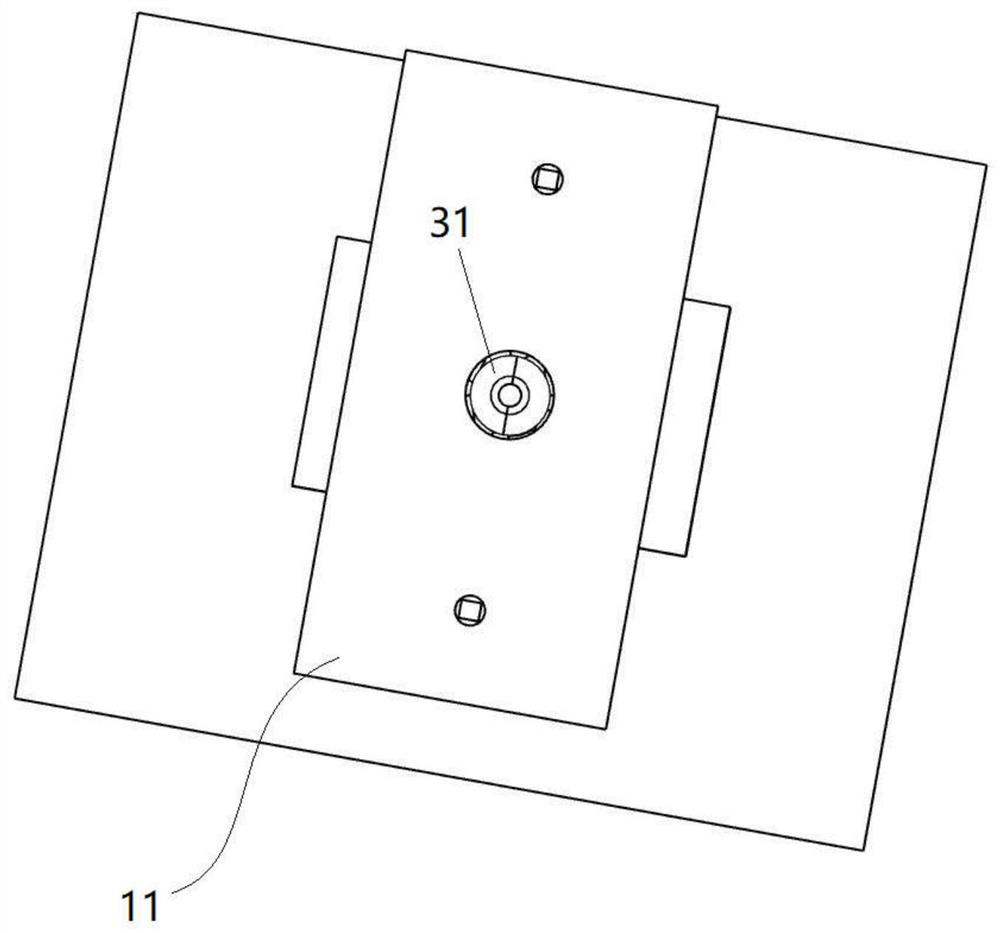

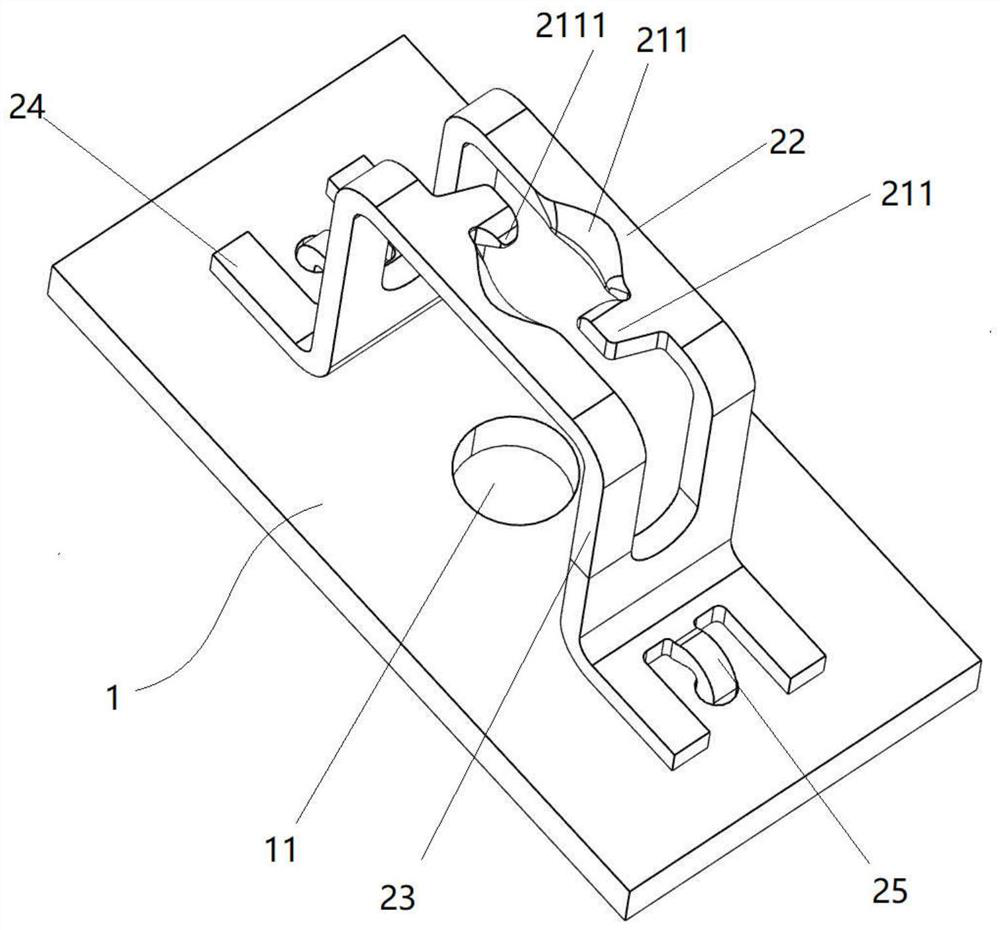

[0032] The PCB board-type connector capable of observing and verifying the annular gap on the back of the present invention includes a PCB board 1 , a positive U-shaped female terminal 2 and a male terminal 3 , see figure 1 and figure 2 . The PCB board 1 is provided with insertion holes 11; both ends of the positive U-shaped female terminal 2 are fixedly connected to the PCB board 1, and the positive U-shaped female terminal 2 is provided with a connecting hole 21; the male terminal 3 includes a A cylindrical connecting pin 31 at the tip, the connecting pin 31 first passes through the connecting hole 21 and then passes through the insertion hole 11 , the inner diameter of the insertion hole 11 is larger than the outer diameter of the male terminal 3 , and only the insertion hole 11 is required in the specific implementation. The inner diameter is slightly larger than the outer diameter of the male terminal 3. The outer wall surface of the connecting pin 31 and the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com