Textile fabric assembly line type dryer

An assembly line and dryer technology, which is applied in the field of textile processing, can solve the problems of cloth folds and hard blocks, and cannot be run in an assembly line, and achieves the effect of realizing circulation, suitable for popularization and use, and avoiding folding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

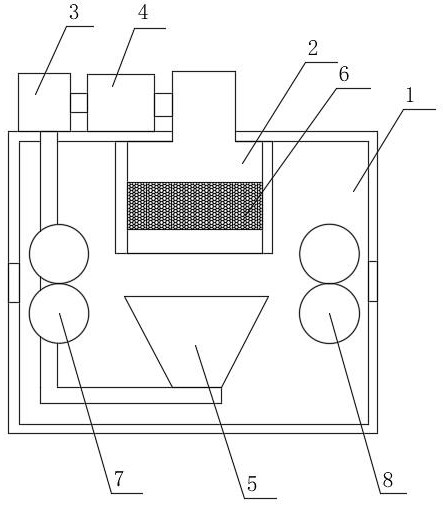

[0017] see figure 1 , this embodiment provides a technical solution:

[0018] A textile and weaving assembly line dryer, comprising a drying box 1, the left and right side panels of the drying box 1 are respectively provided with a material inlet and a material outlet, the inside of the drying box 1 is A feed guide roller 7 and a discharge guide roller 8 are arranged on the inner side of the feed port and the discharge port respectively, and a heating box 2 is fixedly arranged in the middle of the top plate inside the drying box 1, and an opening is arranged at the bottom of the heating box 2, so that An electric heating grid plate 6 is arranged horizontally inside the heating box 2, an air dryer 3 and an air pump 4 are fixedly arranged on the top panel of the drying box 1 from left to right, and an air dryer 3 and an air pump 4 are fixedly arranged on the top panel of the drying box 1. A gas collecting hood 5 is fixedly provided with the heating box 2, the suction pipe of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com