Electronic gear control rocker or electromechanical device or motor vehicle

A joystick and gear technology, applied in mechanical equipment, transmission control, components with teeth, etc., can solve the problems of long matching period of control perception force and short working life of torsion spring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

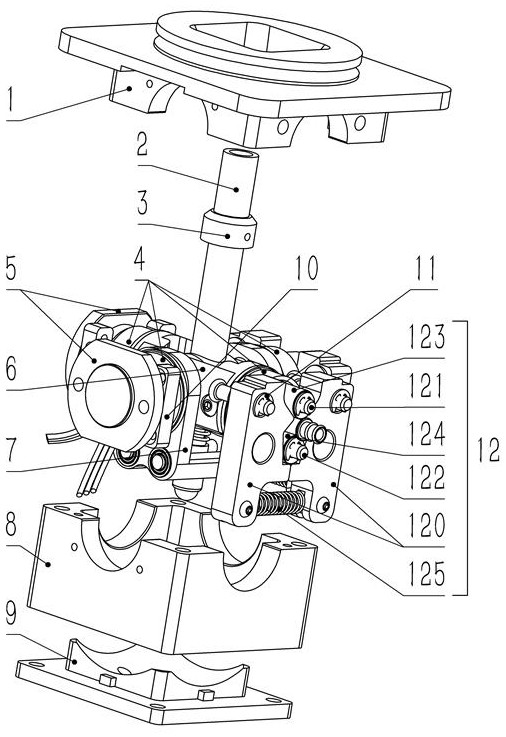

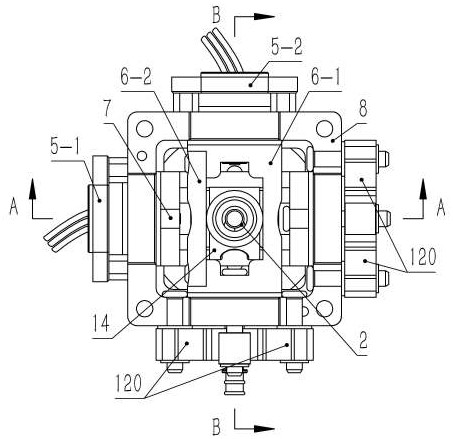

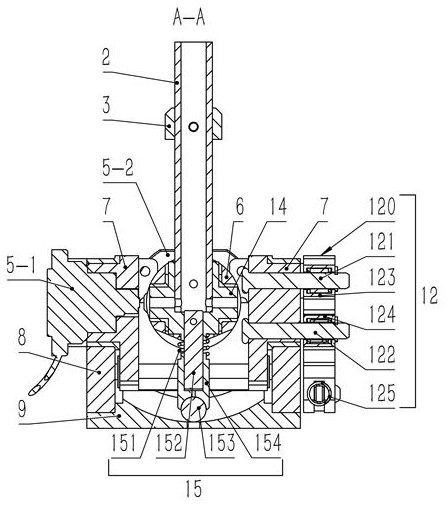

[0149] Such as Figure 1 to Figure 19 As shown, the electronic gear control rocker includes an upper housing 1 and a lower housing 8 through an upper and lower split housing or combined housing 18 .

[0150]The rotating fork 7 and the parting inner core 6 are respectively hinged with the housing or combined housing 18 to form a rotating pair. The shift control lever 2 is fixedly connected to the control lever mounting body 14 . The joystick mounting body 14 is hinged with the parting inner core 6 to form a rotating pair. The joystick installation body 14 is placed in the notch 601 of the split inner core 6 and is hinged to the split inner core 6 through the holes 603 and / or 604 . The articulated steering between the joystick mounting body 14 and the split inner core 6 and the hinged steering between the split inner core 6 and the combination housing 18 are perpendicular. The articulated turning between the swing lever 7 and the combined casing 18 and the articulated turning...

Embodiment 2

[0167] like Figure 14 As shown, in the selection of the sensor, the spatial angular displacement Hall sensor 23 (Hall chip) can be selected, and the spatial angular displacement Hall sensor is fixed on the center of the bottom plate 9 or other positions on the housing, and the elastic slider device 15 Replaced with a magnetic steel mounting device. One end of the magnetic steel mounting device is connected and installed with the control lever or the control lever mounting body 14, and the other end is equipped with a magnetic steel. Preferably, rollers or bearings are installed in the middle of both ends of the magnetic steel installation device. One option is to replace the elastic slider device 15 with a roller 24 and a magnetic steel fixed block 25. The roller 24 can be made of a wear-resistant material, and the magnetic material is placed on the bottom of the magnetic steel fixed block 25. The swing drives the magnetic steel fixed block 25 and the magnetic material to m...

Embodiment 3

[0169] like Figure 15As shown, by adding a sealing shell 26 outside the casing, the electronic gear control rocker can be sealed in the sealing shell 26 except for the outlet position 261, and other structural components can be sealed in the sealing shell 26, and the outlet 501 is connected to the control circuit. The beneficial effect is The electronic gear control rocker device can be used in a harsher environment and has a better dustproof and waterproof effect. The device is easy to install, and four fixed installation holes 106 can be provided on the upper casing 1, and fixed on the panel to be installed by screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com