Formula and processing technology of mine cable sheath

A sheath and formula technology, applied in the field of cable sheath preparation, can solve the problems of no preparation of mine cable sheath, no research on mixed formula, etc., and achieve the effect of easy processing, satisfying use requirements, and high-strength flame-retardant processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

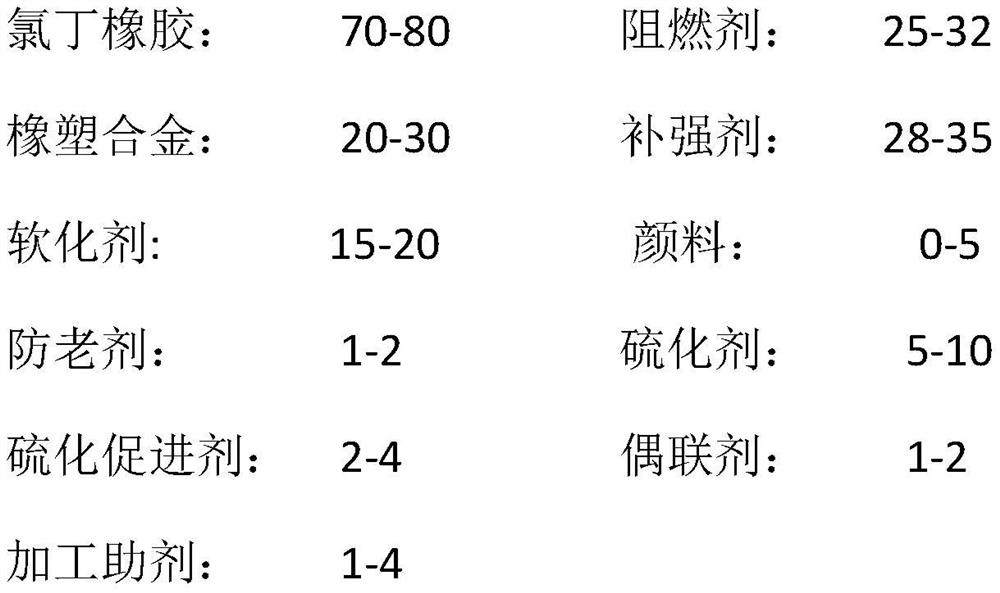

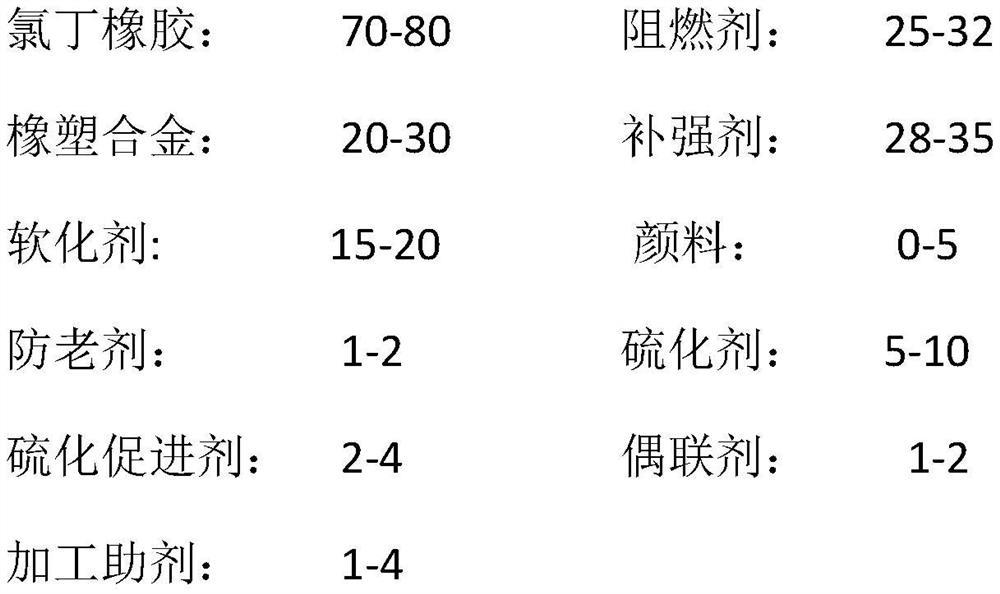

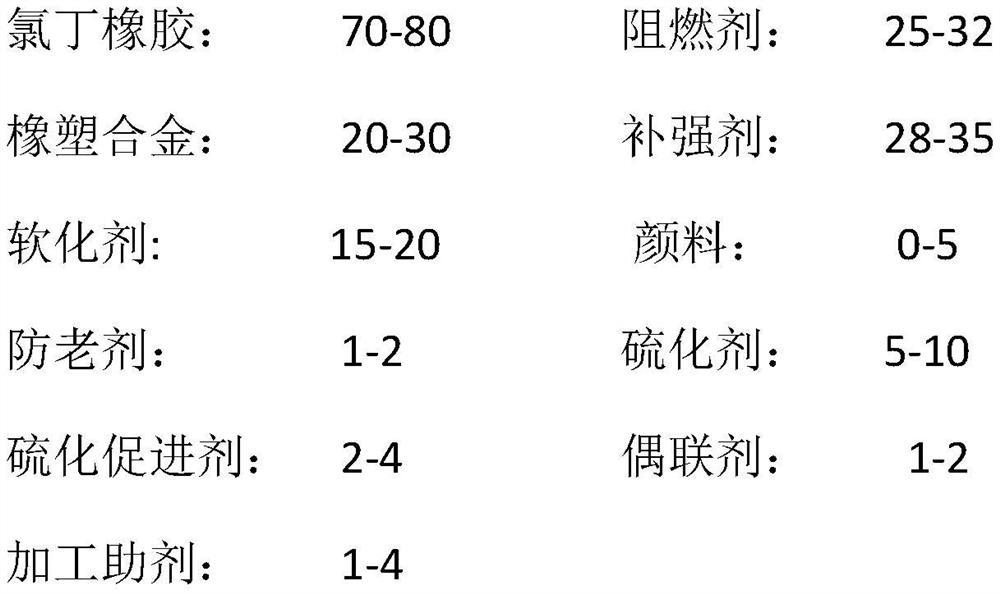

Method used

Image

Examples

Embodiment 2

[0033]Embodiment 2 is aimed at the production process of the yellow mine cable sheath. The sheath formula in Embodiment 2 specifically includes the following raw materials in parts by mass: 75 parts of neoprene rubber, 28 parts of special aluminum hydroxide, 4 parts of antimony trioxide, rubber 25 parts of plastic alloy, 30 parts of white carbon black, 13 parts of 300# paraffin oil, 6 parts of dioctyl phthalate, 3 parts of benzidine yellow, 1 part of HS-911 anti-aging agent, 8.5 parts of zinc oxide as the vulcanizing agent, 0.5 parts of DCP, 1 part of TMTD, 1.3 parts of vulcanization accelerator DM, 1.3 parts of vulcanization accelerator NA-22, 1 part of silane coupling agent Si-69, 1 part of stearic acid, 0.5 parts of zinc stearate;

[0034] The specific processing technology is as follows:

[0035] (1) convert the mass parts according to the formula into the production formula, and strictly proportion by weight; the neoprene rubber of this embodiment adopts CR322, and the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com