Conveyor with brick type folding function

A conveyor and functional technology, which is applied in the field of bricklaying and stacking, can solve problems such as low efficiency, affecting brick stacking output and income, and long cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

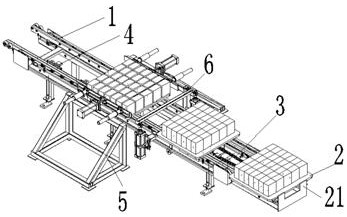

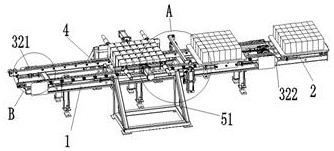

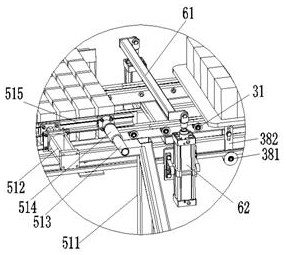

[0021] Such as Figure 1-5 As shown, the present embodiment provides a conveyor with the function of closing bricks, including a frame 1, a stacking station 2, a brick plate conveying device 3, a number of position sensors 4, a controller, and conveying along the brick plate conveying device 3 The horizontal closing device 5 and the longitudinal closing device 6 arranged in sequence in the direction, the horizontal closing device 5 and the longitudinal closing device 6 are arranged successively along the conveying direction of the brick conveying device 3, and each position sensor 4 is installed on the frame 1, and each position sensor 4 and the brick plate conveying device 3 are electrically connected with the controller, the brick plate conveying device 3 is installed on the frame 1, and the horizontal closing device 5 includes two opposite clamping assemblies 51, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com