Multifunctional non-setting adhesive die-cutting machine for label production

A multi-functional, labeling technology, applied in metal processing, etc., can solve the problems of high defective rate of finished labels, increase of enterprise cost, shortage of skilled workers, etc., to avoid mechanical damage, increase friction, and ensure work stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

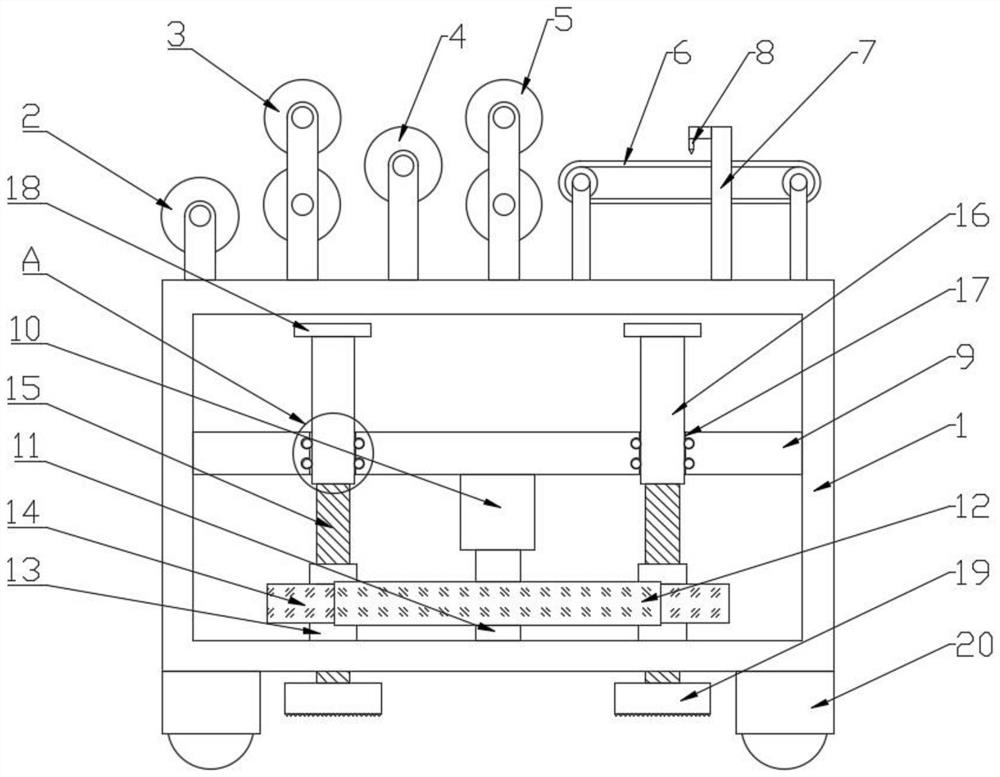

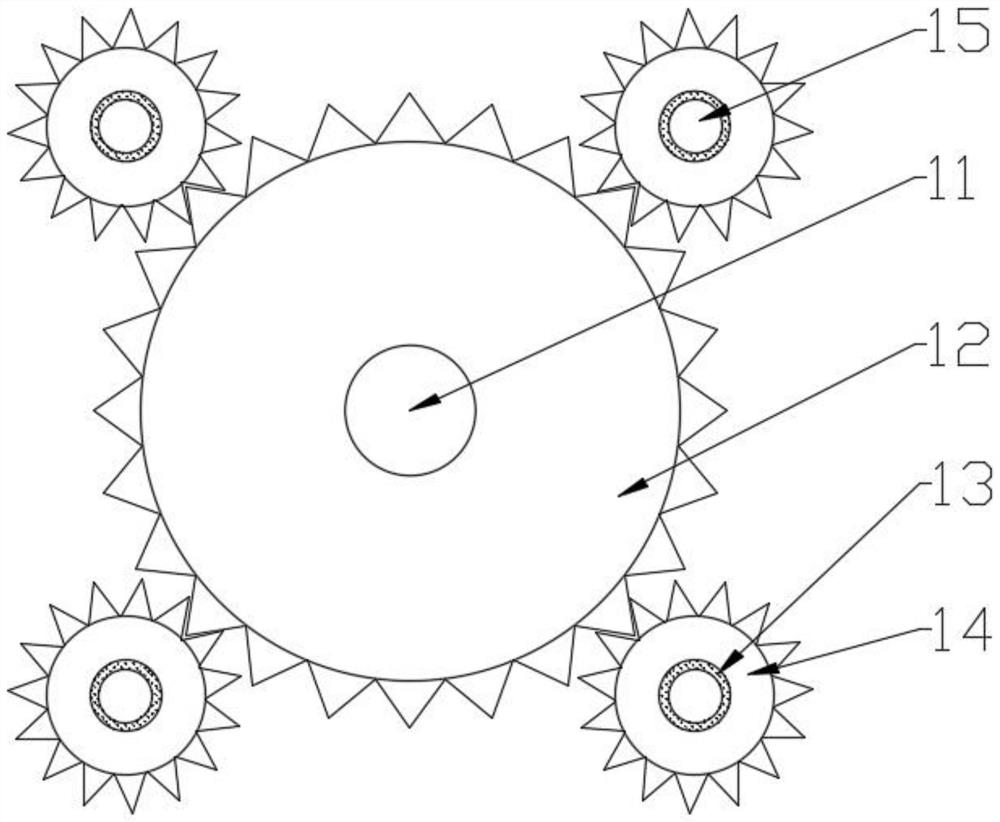

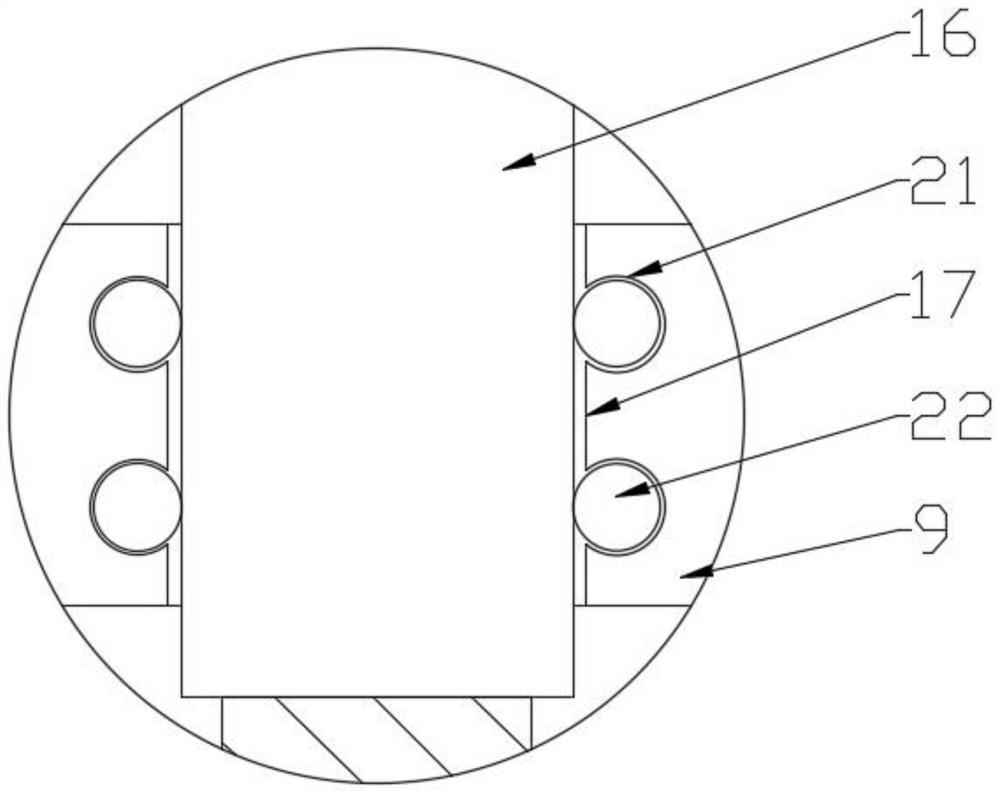

[0032] see Figure 1-3, a self-adhesive die-cutting machine for multifunctional label production, including a workbench 1, a conveyor belt 6 is arranged on the upper side of the workbench 1 to the right, the conveyor belt 6 is fixed on the upper surface of the workbench 1 through a bracket, and the upper surface of the workbench 1 is located on the The front side of the conveyor belt 6 is provided with a die-cutting knife rest 7, and a die-cutting knife 8 is installed on the die-cutting knife rest 7. The upper side of the workbench 1 is provided with a first guide roller 2 and a second guide roller 4 on the left. Between the roller 2 and the second guide roller 4 is provided with the first pinch roller group 3, the right side of the second guide roller 4 is provided with the second pinch roller group 5, the first guide roller 2 and the second guide roller 4 are both The roller support is fixed on the workbench 1, the height of the second guide roller 4 is higher than the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com