Flexible energy gathering line cutter

A wire cutting and energy gathering technology, applied in non-electric welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor structural adaptability and insufficient cutting ability, and achieve good shape adaptability, wide use and simple operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

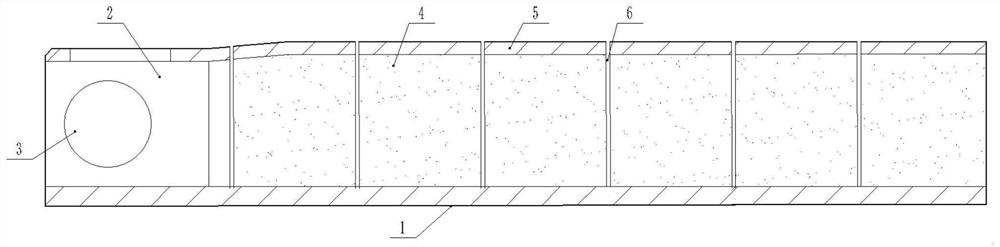

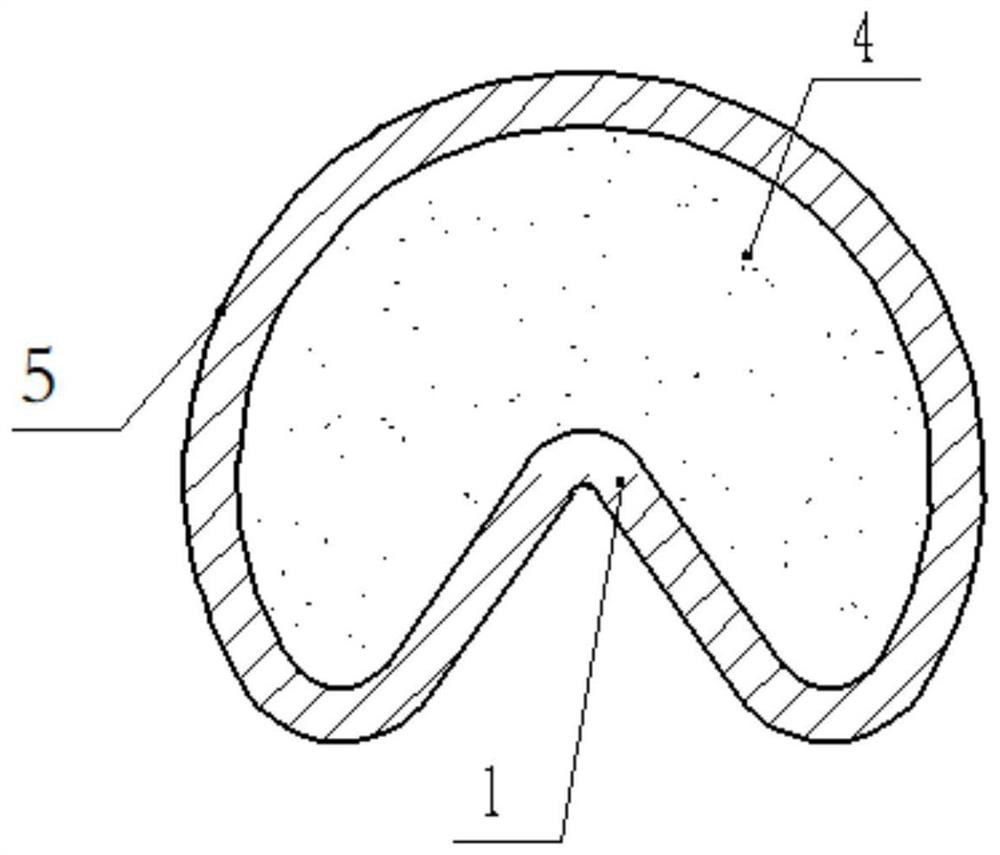

[0026] like figure 1 As shown, a flexible energy-concentrating wire cutter includes a housing 5 with a strip-shaped installation cavity, and the bottom of the housing 5 is recessed into the installation cavity to form an inverted V-shaped drug-shaped cover 1, such as figure 2 As shown, a number of opening slots 6 are opened from top to bottom along the radial direction of the casing 5 on the top of the casing 5 opposite to the explosive assembly.

[0027] The installation cavity is provided with an initiation component and an explosion component, and the explosion component includes a high-energy explosive 4, and the high-energy explosive 4 fills the installation cavity.

[0028] The detonation assembly includes a detonation charge 2, and a detonation hole 3 for placing a detonator is opened on the detonation charge 2. The explosive component is arranged in the installation cavity, and the detonating component for detonating the explosive component is arranged at one end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com