Multifunctional pipeline tapping machine based on plasma cutting

A technology of plasma and hole punching machine, which is applied in plasma welding equipment, tubular articles, applications, etc., can solve the problems of high wear rate of cylinder cutter, low hole punching efficiency, and bulky products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] First of all, it needs to be explained that the orientation words such as up, down, left, right, front, and back described in the present invention are only described according to the accompanying drawings, so as to be easy to understand, and are not intended to limit the technical solution and scope of protection of the present invention. .

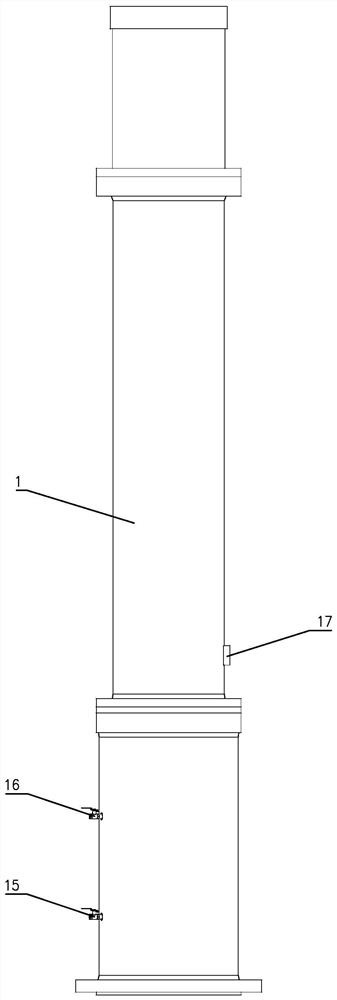

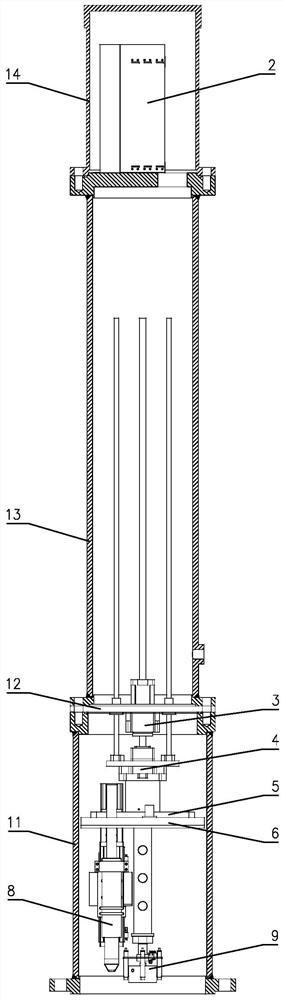

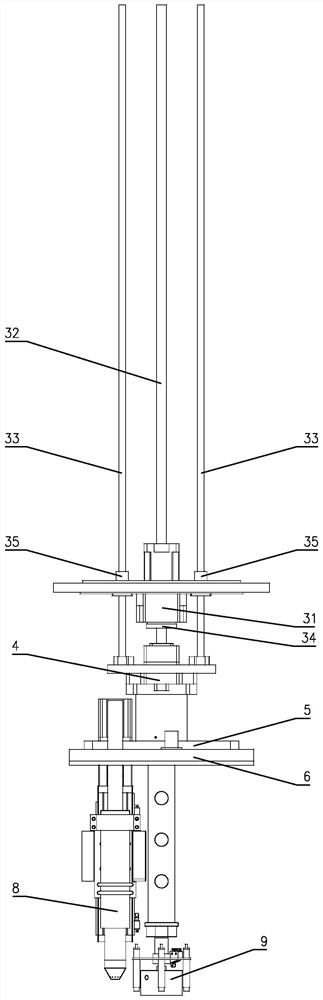

[0052] Such as Figure 1 to Figure 35 Shown is a specific embodiment of a plasma cutting-based multifunctional pipeline drilling machine of the present invention, including a casing 1 and a control device 2 , a lifting device 3 and a drilling device disposed in the casing 1 . The opening device includes a pan-tilt assembly 4 , a swing arm assembly 5 , a protection assembly 6 , a slide rail assembly 7 , a cutting assembly 8 and a material lifting assembly 9 . The pan-tilt assembly 4 is provided with a pan-tilt support plate 41 connected to the lifting device 3, a first hollow rotary table 42 is installed on the pan-tilt support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com