Improved curative composition

A technology of curing agent and mixture, applied in the field of curing agent preparation, can solve the problems of thickening and cannot be used as a single-component epoxy resin composition, and achieve the effect of rapid curing

- Summary

- Abstract

- Description

- Claims

- Application Information

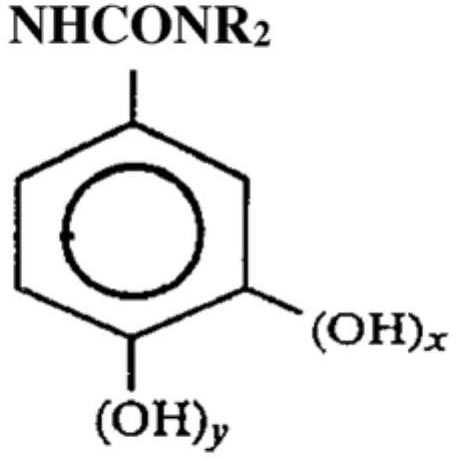

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 5

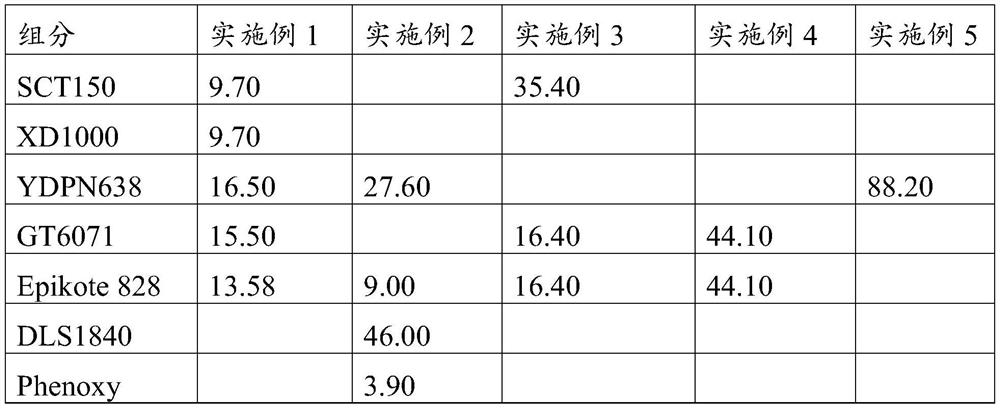

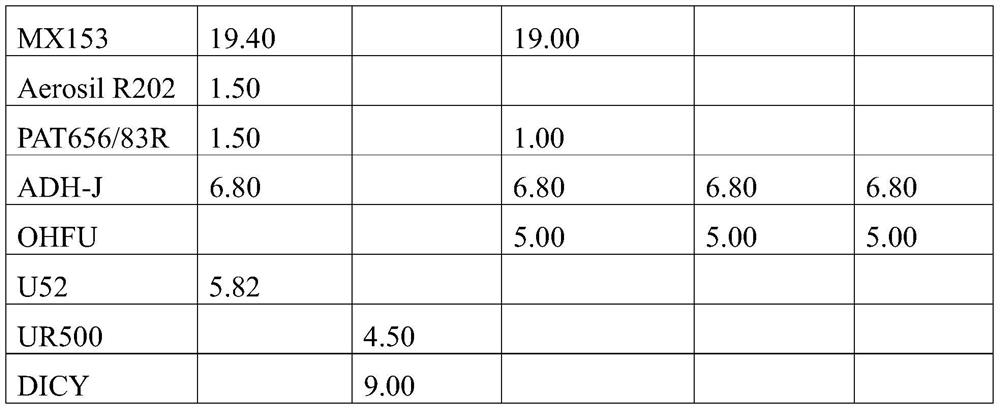

[0091] The following formulations were prepared.

[0092] Table 3. Formulations of Examples 1 to 5

[0093]

[0094]

[0095] The formulations of Examples 1 to 5 were exposed to a temperature of 150°C, the time to 95% cure and the E'Tg were measured and the results are as follows.

[0096] Table 4. Results of Examples 1 to 5.

[0097]

[0098] The following examples show the effect of curing agent on the combination of time to 95% cure and E'Tg.

Embodiment 3 and 6 to 10

[0100] The following formulations were prepared.

[0101] Table 5. Formulations of Examples 3 and 6 to 10

[0102]

[0103]

[0104] The formulations of Examples 3 and 6 to 10 were exposed to a temperature of 150°C and the time to 95% cure and E'Tg were measured and the results are as follows (Table 6).

[0105] Table 6. Results of Examples 3 and 6 to 10

[0106]

Embodiment 11 to 13

[0108] Finally, the formulations of Examples 11 to 13 below were prepared.

[0109] Table 7. Formulations of Examples 11 to 13

[0110] components Example 11 Example 12 Example 13 SCT150 34.2 20 33.8 XD1000 YDPN638 27.60 GT6071 16.4 16 15.50 Epikote 828 16.4 16 15.50 MY721 15 Phenoxy MX153 19 19.00 Aerosil R202 PAT656 / 83R 1 1 1.00 ADH-J 6.80 6.8 OHFU 6.2 6.2 6.2 U52 UR500 DICY 9.0

[0111] The formulations of Examples 11, 12 and 13 were exposed to a temperature of 150°C, the time to 95% cure and the E'Tg were measured and the results are as follows.

[0112] Table 4. Results of Examples 15 to 17.

[0113] Measurement Example 11 Example 12 Example 13 Time to reach 95% curing (minutes) 2.4 1.9 1.7 E'Tg(°C) 142 140 138

[0114] These examples show that reduced time to 95% cure and in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com