Flexible zero-buoyancy photoelectric composite trailing cable

A photoelectric composite, zero buoyancy technology, applied in the direction of power cables, power cables including optical transmission elements, insulated cables, etc., can solve the problems of difficult towing use environment, low compressive strength, low tensile strength, etc., to reduce weight, Improved strength, roundness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

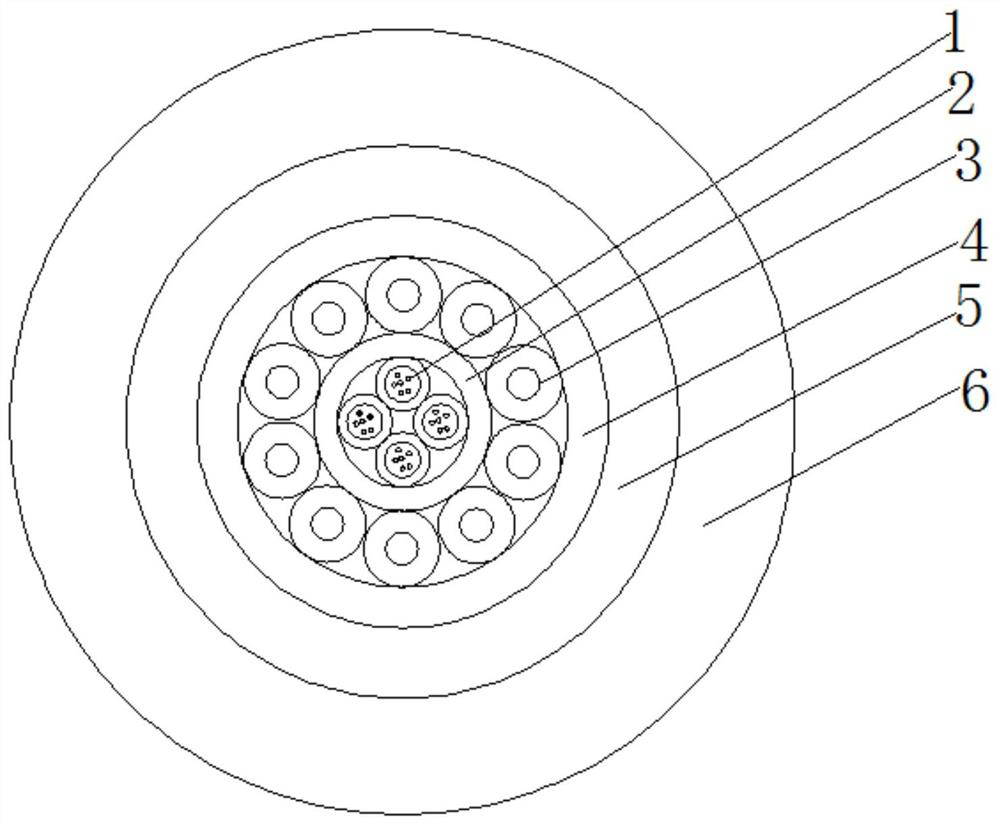

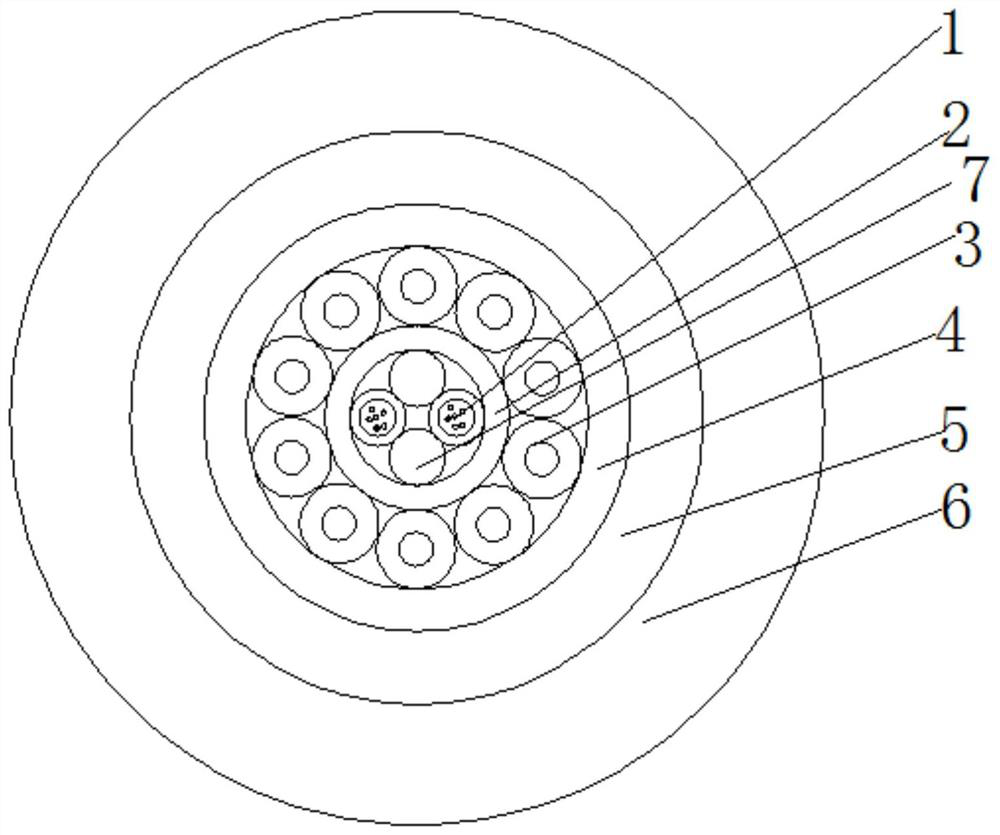

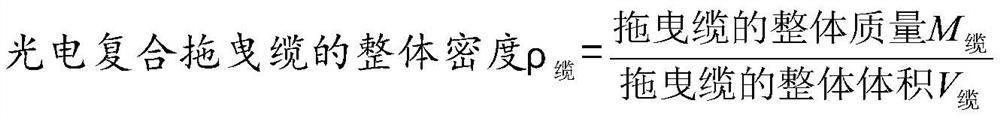

[0028] refer to figure 1 As shown, an embodiment of the flexible zero-buoyancy photoelectric composite trailing cable of the present invention includes a light unit 1 arranged in the center and an inner sheath layer 2, a power unit 3, and a middle sheath layer 4 that are sequentially coated outside the light unit 1 , a flexible strengthening unit 5 and an outer sheath layer 6, the power unit 3 is helically twisted on its outer periphery along the extension direction of the inner sheath layer 2 with the inner sheath layer 2 as the axis, so as to ensure the roundness and uniformity of the cable as a whole Stable, more suitable for reciprocating retractable working conditions. The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com