Ultrasonic sensor and preparation method and application thereof

A sensor and ultrasonic technology, applied in the field of sensors, can solve problems such as increased cost and complex sensor structure, and achieve the effect of improving measurement accuracy and eliminating the influence of air bubbles on sensor measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

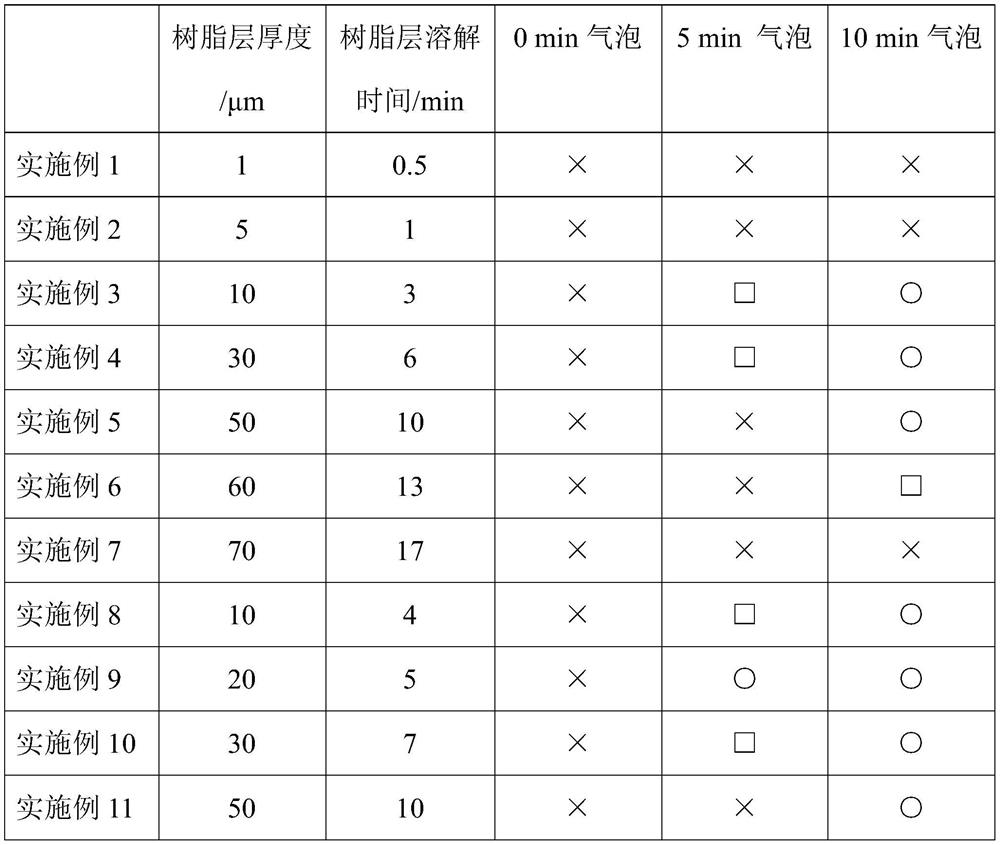

Embodiment 1

[0037]This embodiment provides an ultrasonic sensor, the transmitting / receiving surface and the reflecting surface of the ultrasonic sensor are both coated with a water-based acrylic resin (component: acrylic resin, content of 55.5%, water, content of 44.5%) with a thickness of 1 μm.

[0038]The specific preparation method is as follows: coating water-based acrylic resin on the transmitting / receiving surface and reflective surface of the ultrasonic sensor, and drying at 10°C for 40 minutes to obtain an ultrasonic sensor with both the transmitting / receiving surface and the reflective surface coated with water-based acrylic resin.

Embodiment 2-7

[0040]The difference from Example 1 is only that the thickness of the water-based acrylic resin is 5μm (Example 2), 10μm (Example 3), 30μm (Example 4), 50μm (Example 5), 60μm (Example 6) ), 70 μm (Example 7).

Embodiment 8

[0042]The difference from Example 3 is that the water-based acrylic resin on the transmitting / receiving surface and the reflective surface is replaced with water-based polyvinyl alcohol resin of the same thickness (composition: polyvinyl alcohol, content is 13.4%, water content is 86.6%) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com