Small-leakage-rate positive-pressure leakage hole calibration method and device

A technology of positive pressure leaks and calibration methods, applied in measuring devices, by measuring the acceleration and deceleration rates of fluids, instruments, etc., can solve the problems of many gas molecules, low efficiency, and great influence of pressure and temperature, so as to shorten the time interval, Accurate detection results and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

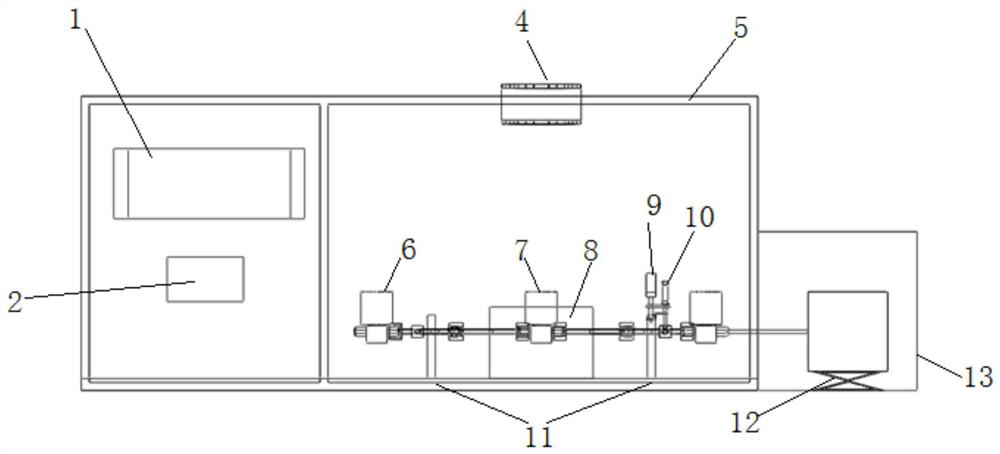

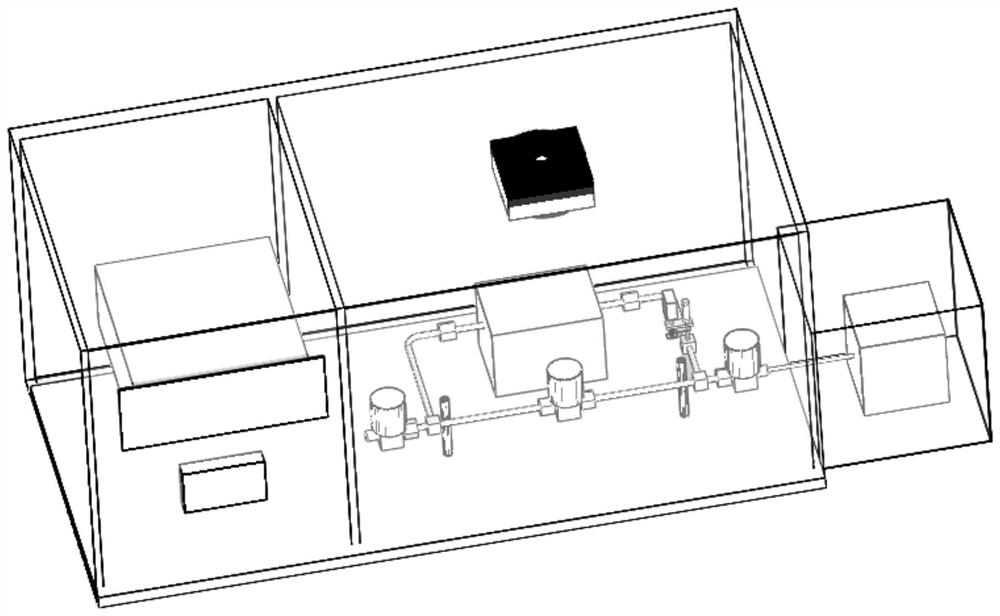

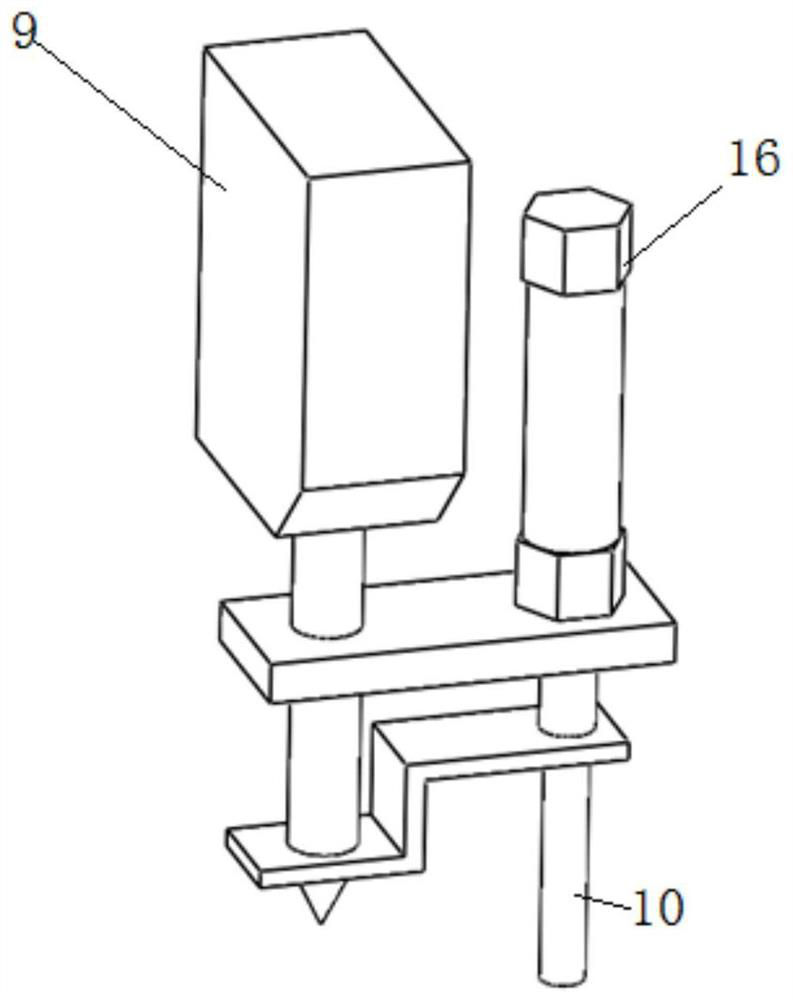

[0034] see Figure 1-2 , Figure 1-2 Schematic diagram of the self-developed positive pressure leak calibration device. It is mainly composed of a volume measurement system composed of a capacitive scale and a piston, a constant temperature system composed of a semiconductor refrigeration module and a PID control, a differential pressure film gauge, three high-precision pneumatic surface sealing valves and a vacuum pipeline. Among them, the pipeline between the differential pressure film gauge, the test valve and the shut-off valve forms the calibration room, and the pipeline between the differential pressure film gauge, the vent valve and the shut-off valve forms the reference room.

[0035] The traditional positive pressure leak calibration method is to connect the leak to be calibrated with the calibration chamber. As the gas leaks into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com