Fireproof structure and installation method for smoke prevention and exhaust duct

A technology of fireproof structure and installation method, applied in the direction of pipes, applications, rigid pipes, etc., can solve the problems of not being able to ensure life safety well, and the fire resistance limit of smoke and exhaust ducts is short, so as to achieve tight packaging and improve heat resistance , the effect of tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

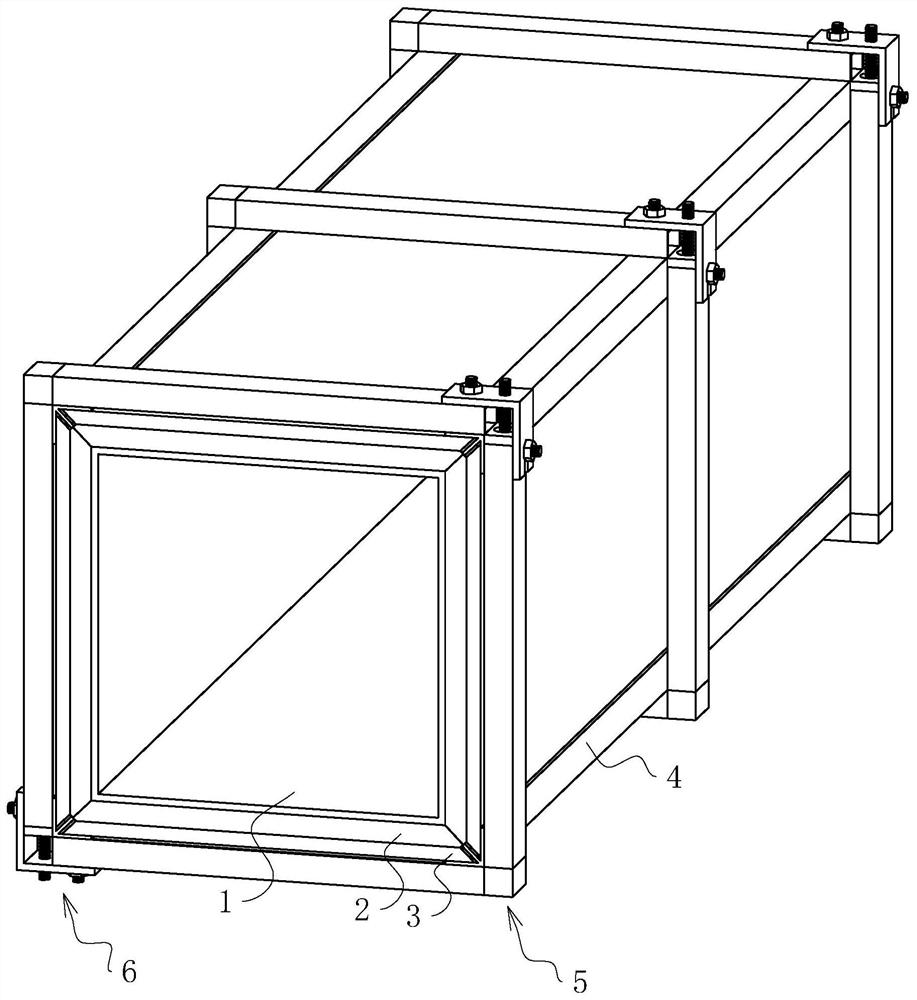

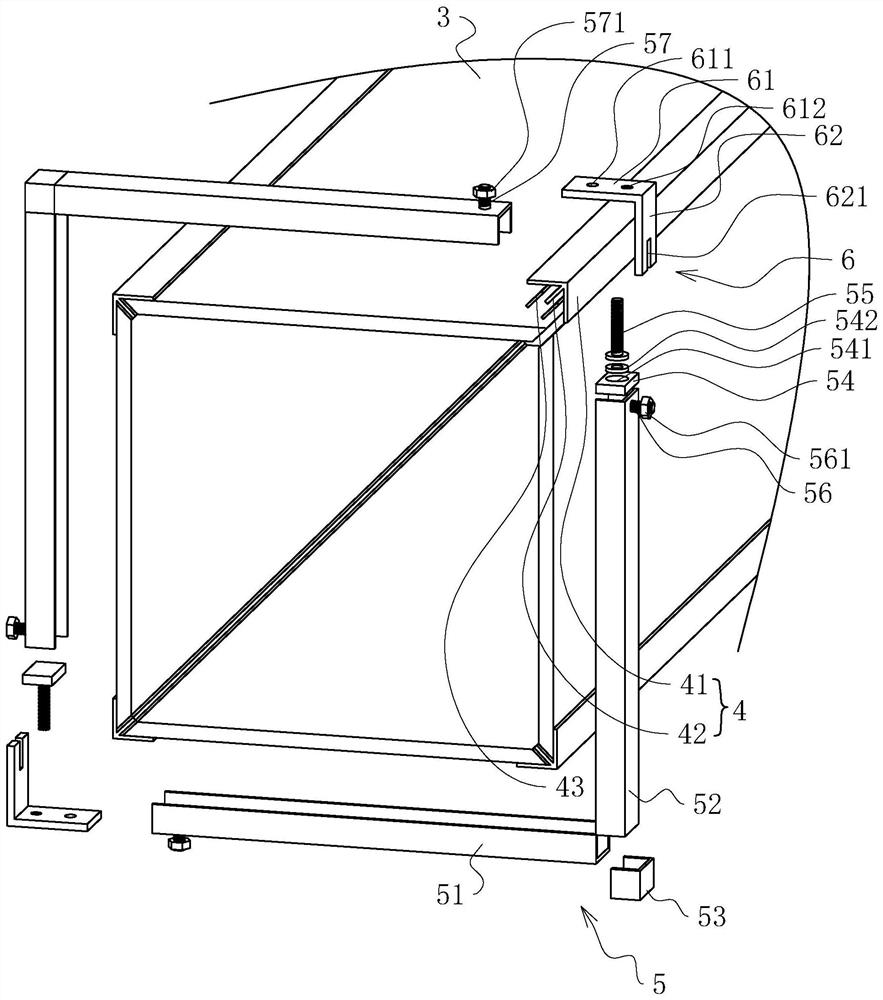

[0058] refer to figure 1 , a fireproof structure for the smoke prevention and exhaust air duct, including several sections of heat insulation layers wrapped on the outer surface of the smoke prevention and exhaust air duct 1, the heat insulation layer is specifically rock wool material, and the several sections of heat insulation layers are arranged with equal lengths. Taking one section of the heat insulation layer as an example, each section of the heat insulation layer is wrapped with four fireproof boards 3 and four edge strips 4, and each section of the heat insulation layer is provided with three fixing devices for fixing the heat insulation layer , the three fixing devices are respectively located at the two ends and the middle of the corresponding smoke prevention and exhaust duct 1 .

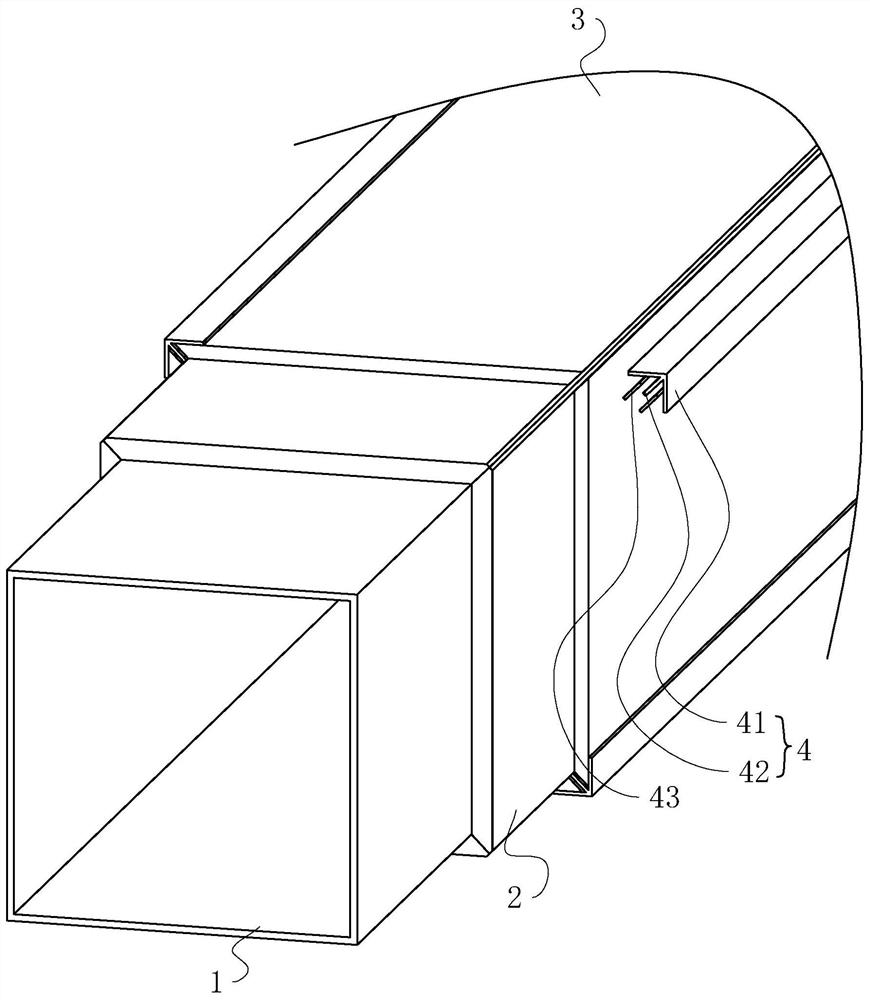

[0059] refer to figure 2 , the length of each section of heat insulation layer can be set between 0.8m and 1.2m according to the actual situation, each section of heat insulation laye...

Embodiment 2

[0070] The difference between this embodiment and embodiment 1 is: refer to Figure 4 , each connecting piece 6 includes a first stabilizing plate 63 and a second stabilizing plate 64 . The second C-shaped steel 52 in each fixture 5 is fixedly connected with a fixed screw rod 58 on the end face away from the first C-shaped steel 51, and the fixed screw rod 58 is threaded with a fixed nut 581; the first C-shaped steel in each fixed piece 5 The side of the end of the section steel 51 away from the second C-section steel 52 is fixedly connected with a stabilizing screw 59 , and the stabilizing screw 59 is threaded with a stabilizing nut 591 .

[0071] refer to Figure 4 A groove 7 is provided on the side of the second C-shaped steel 52 in each fixture 5 away from the end of the first C-shaped steel 51, and a spring 71 is fixedly connected to the groove bottom of the groove 7, and the spring 71 is far away from the groove 7. One end of the bottom of the groove is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com