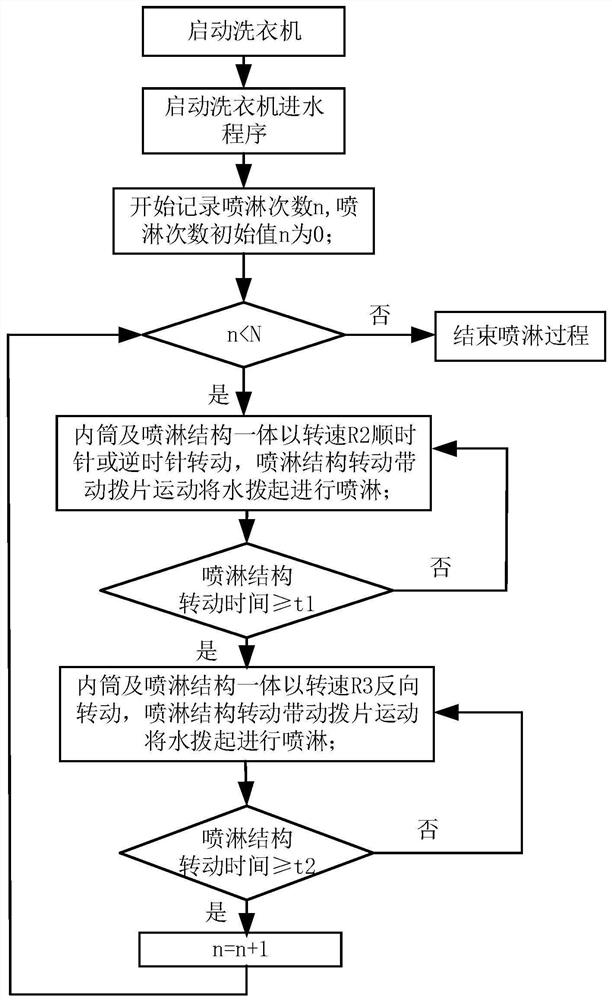

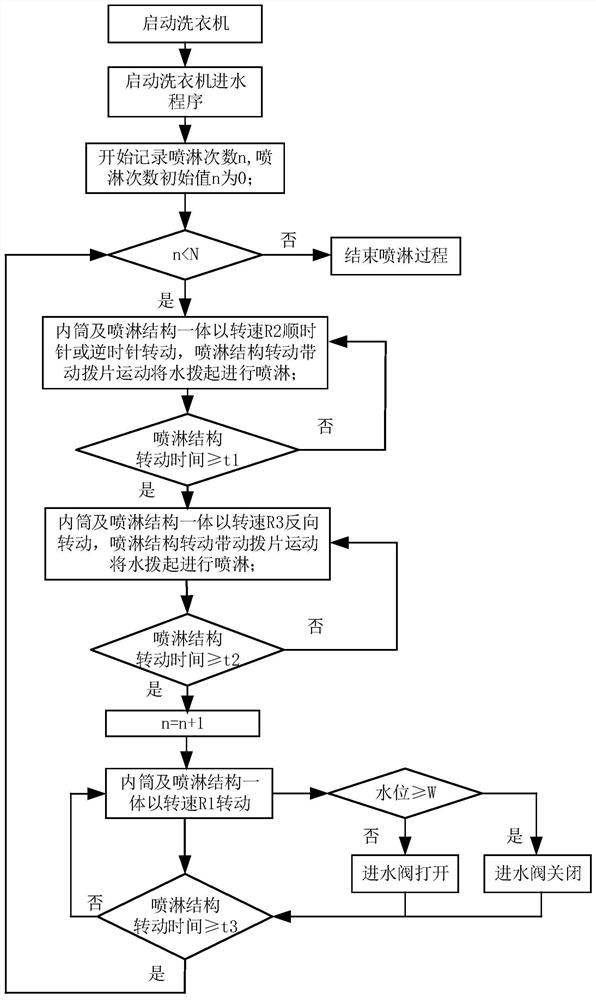

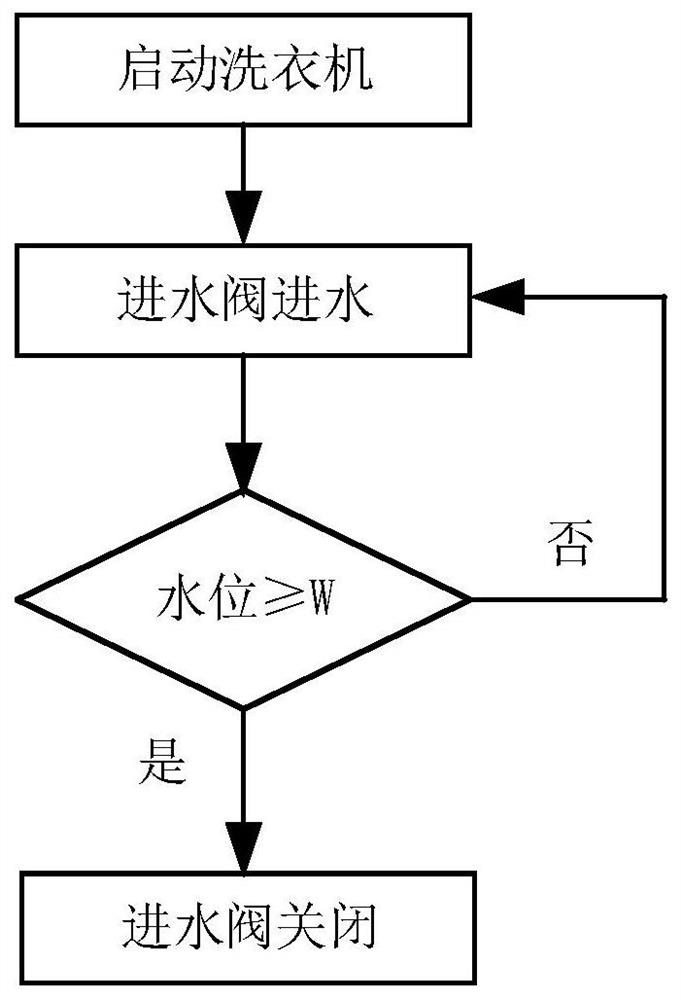

Spraying method of roller washing machine

A drum washing machine, washing machine technology, applied in the control device of washing machine, washing device, textile and paper making, etc., can solve the problems of time-consuming process of soaking clothes, less washing volume of drum washing machine, easy residual detergent foam, etc. The number of showers, the effect of improving laundry efficiency, and improving the efficiency of clothing soaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

[0050] The present invention proposes a spraying method for a drum washing machine, referring to Figure 5-Figure 10 , the front-loading washing machine includes a casing 1, on which an inlet 11 is formed. Generally, the inlet 11 is arranged on the front side of the casing 1. A door body 2 is provided on the front side of the box body 1 , and the door body 2 is adapted to the input port 11 to open or block the input port 11 . The door body 2 includes a glass door 21 for observing the washing conditions in the washing machine.

[0051] It should be noted that, when the drum washing machine is in use, the side facing the user is the front side.

[0052] The drum washing machine 100 also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com