Vehicle-mounted skid-mounted soil leaching system

A soil rinsing and skid-mounted technology, applied in the field of soil remediation, can solve the problems of low treatment efficiency, large amount of contaminated soil treatment, and low device capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

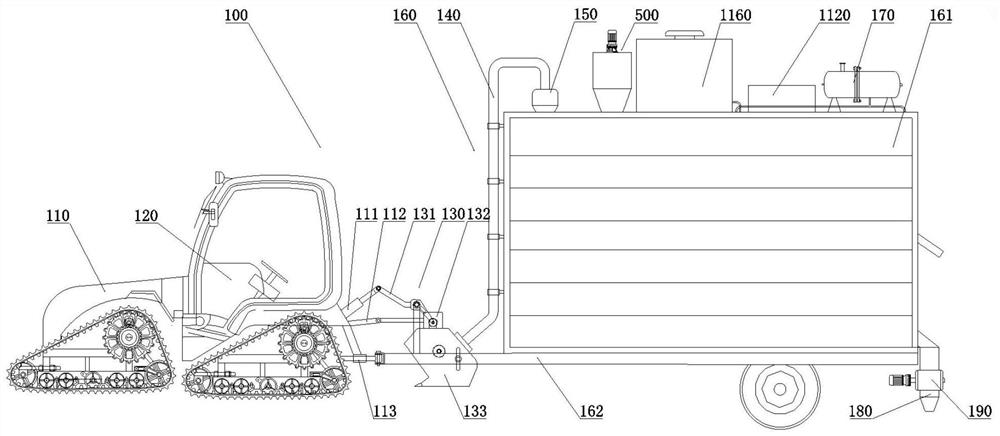

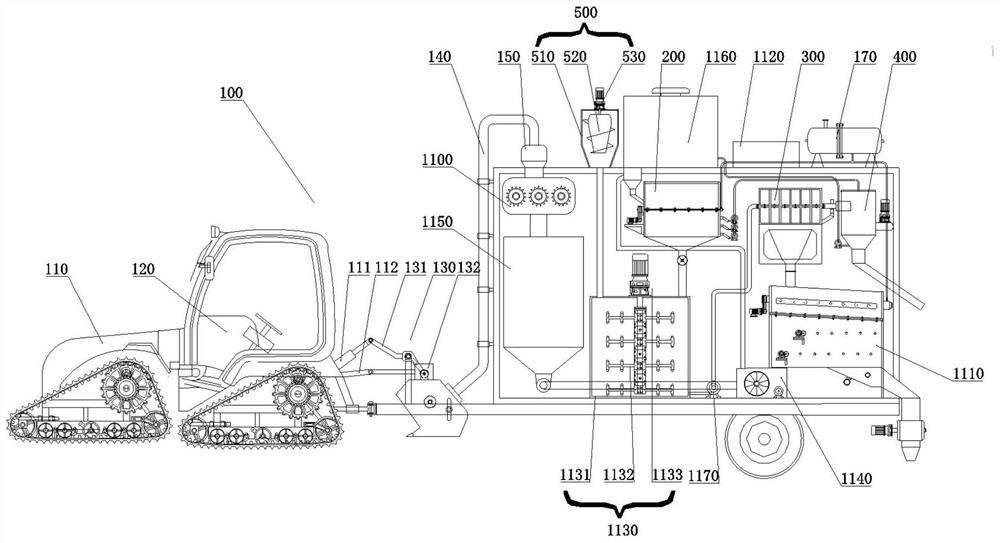

[0042] see Figure 1 to Figure 11 , the present invention discloses a vehicle-mounted skid-mounted soil washing system. The soil washing system 100 includes a crawler tractor 110 and a soil repair vehicle 160 towed by the crawler tractor; the crawler tractor is widely applicable, especially for hills, Mountain work.

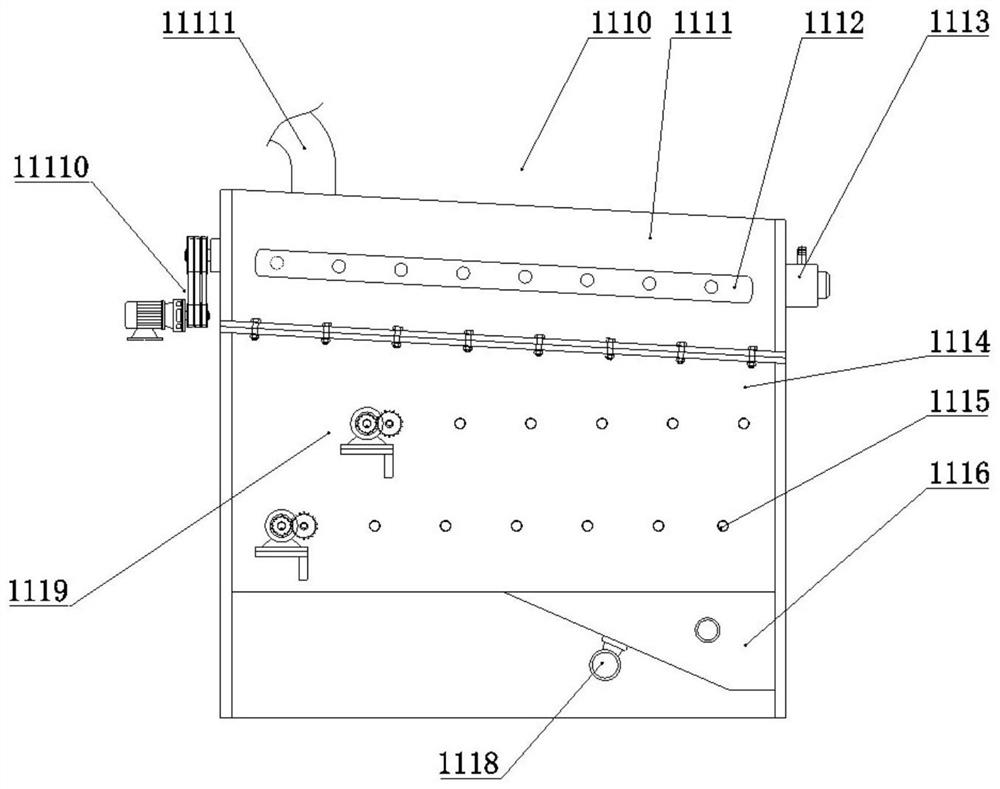

[0043] The soil remediation vehicle 160 includes a container body 161 and a frame chassis 162 for carrying the container body; the front end of the frame chassis 162 is provided with a milling and excavating device 130 drivingly connected to a crawler tractor, and the milling and excavating device 130 includes Milling box 133, the milling box 133 includes a milling bucket 1331 and a milling roller 1335 that is rotated and arranged in the milling bucket. Several shovel heads 1332 are arranged on the bucket to increase the prying effect on the polluted soil; the milling bucket 1331 can also be provided with an upwardly inclined baffle plate 1333 to facilitate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com