Mask processing raw material feeding system

A technology for processing raw materials and feeding systems, applied in the direction of dissolution, mixers, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

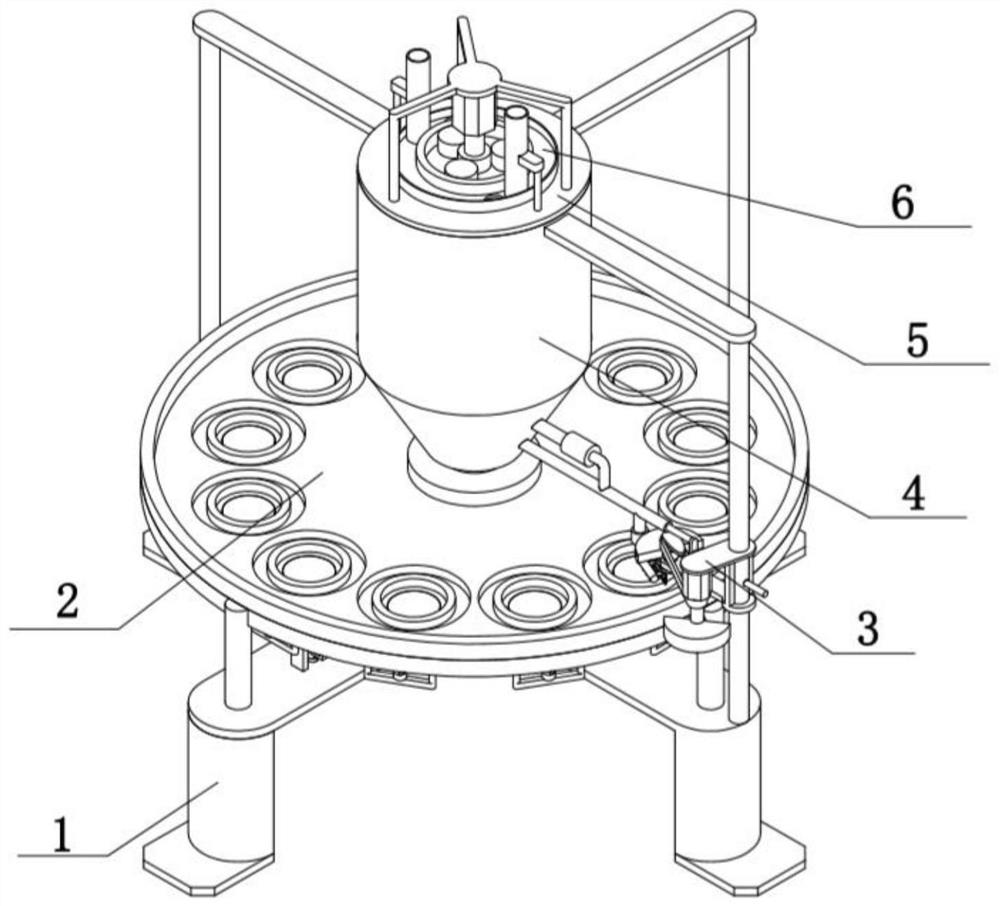

[0033] Combine below Figure 1-10 Describe this embodiment, a raw material feeding system for facial mask processing, including a supporting blanking assembly 1, a forming assembly 2, a driving assembly 3, a discharging assembly 4, a stirring assembly 5 and a blanking assembly 6, and the forming assembly 2 is rotatably connected On the supporting blanking assembly 1, the driving assembly 3 is fixedly connected to the supporting blanking assembly 1, the forming assembly 2 and the driving assembly 3 are engaged for transmission, the discharging assembly 4 is connected to the supporting blanking assembly 1, the driving assembly 3 and the discharging The components 4 are engaged with transmission, the agitating component 5 is fixedly connected to the discharging component 4 , and the unloading component 6 is rotatably connected to the agitating component 5 .

[0034] It is possible to drive the feeding assembly 6 by starting the stirring assembly 5 to realize the feeding of the fe...

specific Embodiment approach 2

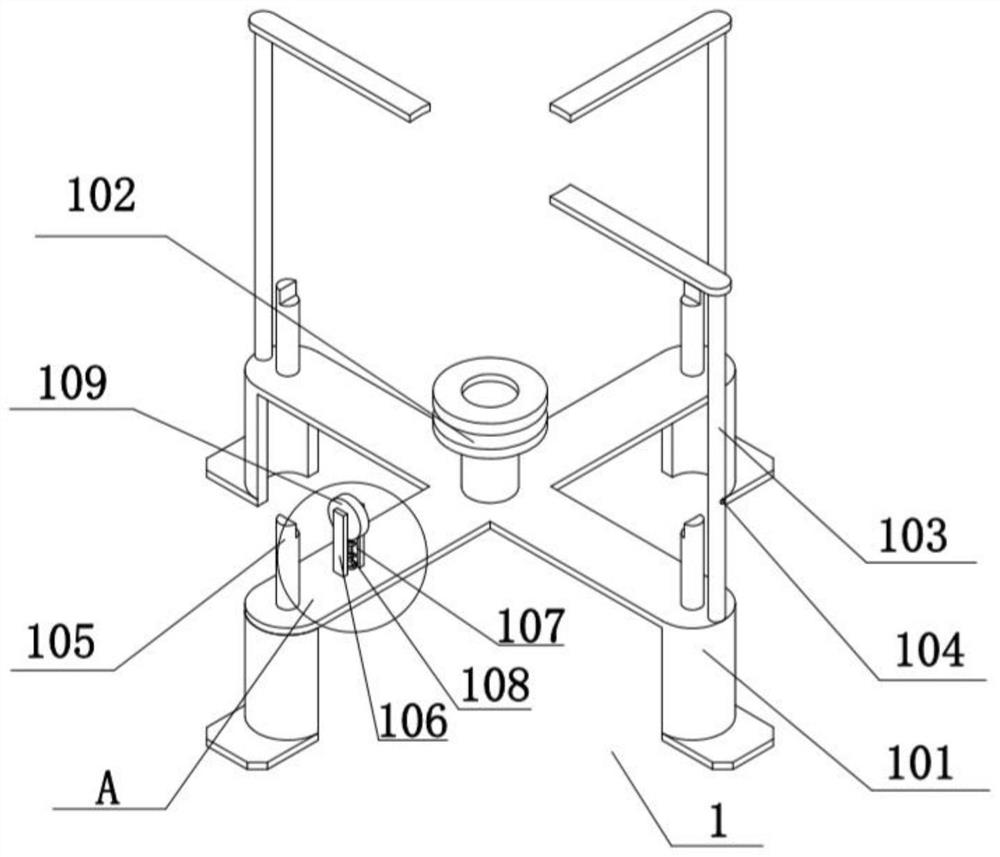

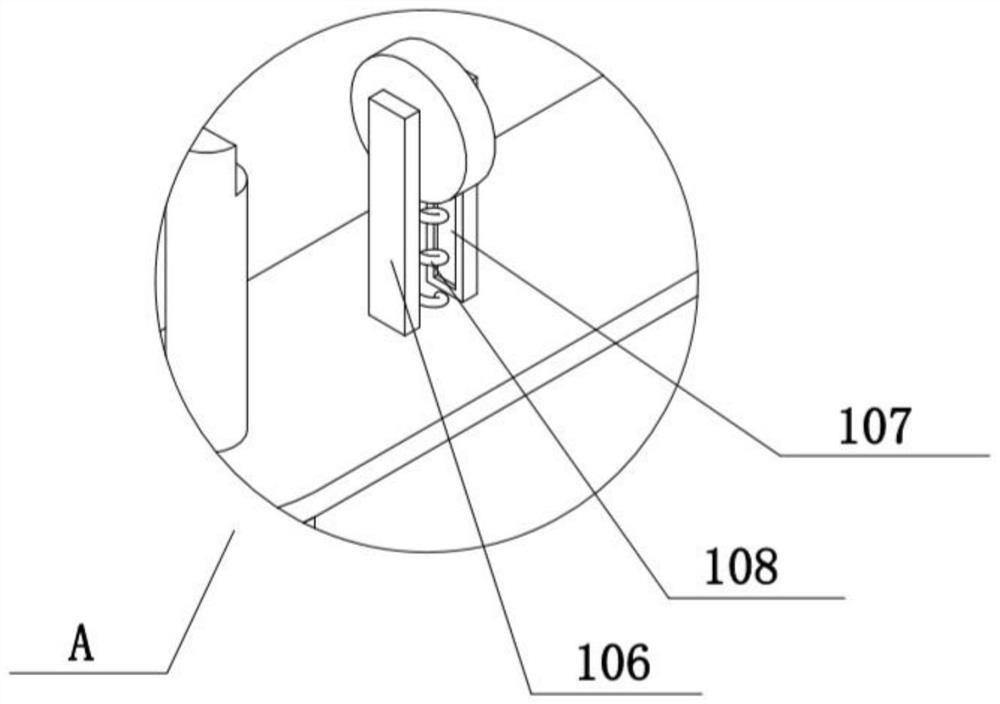

[0036] Combine below Figure 1-10 To illustrate this embodiment, the supporting blanking assembly 1 includes a bracket 101, a rotating mounting table 102, a vertical rod 103, a sliding hole 104, an auxiliary table 105, a blanking vertical plate 106, a sliding groove 107, a blanking spring 108 and a blanking spring 108. Wheel 109, the middle part of support 101 is fixedly connected with rotating installation platform 102, is evenly distributed with a plurality of auxiliary platforms 105 on the support 101, and the left and right sides and the rear end of support 101 are all fixedly connected with upright bar 103, on a plurality of upright bar 103 Both are provided with sliding holes 104, and the two blanking vertical plates 106 are fixedly connected to the front side of the support 101, the two blanking vertical plates 106 are provided with sliding grooves 107, and the blanking springs 108 are fixedly connected to the support 101, The blanking spring 108 is located between the tw...

specific Embodiment approach 3

[0038] Combine below Figure 1-10 To illustrate this embodiment, the forming assembly 2 includes a forming disc 201, an outer ring gear 202, a forming step 203, a recovery groove 204, a blanking plate 205, a reset plate 206, a return spring 207 and a limit plate 208, and the forming disc 201 rotates Connected to the rotating mounting table 102, the outer ring gear 202 is fixedly connected to the forming disc 201, the forming disc 201 is evenly distributed with a plurality of forming steps 203, and the forming disc 201 is evenly distributed with a plurality of recycling grooves 204, and a plurality of forming steps 203 corresponds to a plurality of recovery grooves 204 one-to-one, and a plurality of forming steps 203 are slidingly connected with a blanking plate 205, and the lower ends of a plurality of blanking plates 205 are fixedly connected with two reset plates 206, and the plurality of reset plates 206 and the forming Return springs 207 are fixedly connected between the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com