A big data self-piercing riveting joint key geometrical parameter prediction system and method

A technology of geometric parameters and self-piercing riveting, applied in geometric CAD, neural learning methods, special data processing applications, etc., can solve the problems of large detection error, poor effect of thin joints, and inability to judge the internal deformation characteristics of self-piercing riveting joints, etc. To achieve the effect of solving low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

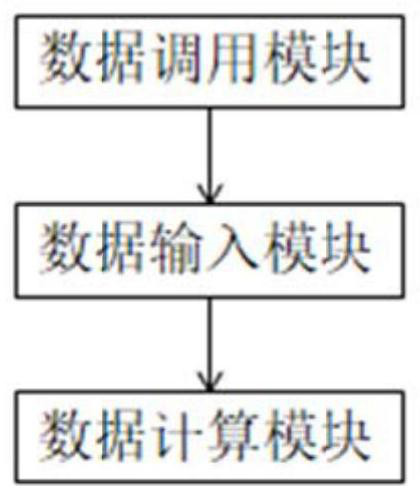

[0063] combine figure 1 and figure 2 , the present invention provides a large data prediction system for key geometric parameters of self-piercing riveting joints, including: a data call module, a data input module and a data calculation module;

[0064] Data calling module: according to the type of joint mold to be tested, determine the pre-trained network model corresponding to the mold type;

[0065] Data input module: input the process parameters of the joint to be tested to the pre-trained network model to obtain the opening value of the nail foot and the self-locking value of the nail foot of the joint to be tested;

[0066] Data calculation module: calculate the key geometric parameters of the joint to be tested according to the opening value of the nail foot of the joint to be tested;

[0067] The key geometric parameters include the height of the nail head and the bottom thickness of the joint;

[0068] The pre-trained network model is obtained by training the his...

Embodiment 2

[0099] combine figure 2 , a system and method for predicting key geometric parameters of self-piercing riveting joints based on big data. The system includes a material database, a training sample database, a data call module, a data input module, a data calculation module, and a result display module.

[0100] Material database includes material alloy grade, thickness, hardness, yield strength and tensile strength;

[0101] The training sample database is obtained through actual process tests and simulation model calculations. For different bottom mold types, different samples are formed. Determine the training sample database under four bottom mold parameters, namely φ3.0~3.4mm rivet flat mold, φ3.0~3.4mm rivet punch, φ5.0~5.4mm rivet flat mold, φ5.0~5.4mm Rivet punch; the training sample database includes alloy grades, plate thickness, rivet specifications, bottom die depth, riveting speed, and nail foot opening and self-locking values under corresponding process condi...

Embodiment 3

[0119] 5182-O state aluminum alloy plate, the thickness of the upper and lower plates is 1.5mm, the size of the rivet is φ5.3×5.5mm, the size of the bottom mold, combined Figure 5 , the depth is h=2mm. 5182-O state aluminum alloy plate riveting process parameters are as follows: t 1 = 1.5mm, h 1 =80HV,σ 1 =280MPa; t 2 = 1.5mm, h 2 =80HV,σ 2 =280MPa; D 0 =5.3mm, V=60cm / min.

[0120] (1) Use the data calling module to call the φ5.3 punch.

[0121] (2) put t 1 = 1.5mm, h 1 =80HV,σ 1 =280MPa; t 2 = 1.5mm, h 2 =80HV,σ 2 =280MPa; D 0 =5.3mm, V=60cm / min parameters are input to the data input module;

[0122] (3) According to the training sample called by the φ5.3 punch, calculate the opening value of the joint nail foot D = 7.32mm, and the self-locking value u = 0.43mm;

[0123] (4) Using h=(D 模 -D 0 )·tanα / 2-L 帽 , s=t 1 +t 2 +H 模 -L 帽 -L 脚 cos α-h; α=arcsin(D-D 0 ) / 2L 脚 The formula calculates the nail head height h=0.05mm, and the bottom thickness value s=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com