Adjusting-type spray gasifier group

A gasifier and spray type technology, which is applied in the field of gasifiers and can solve the problems of non-adjustable gasification efficiency of the gasifier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to solve the gasifier in the prior art, the liquid phase medium absorbs the heat of the external air through the finned tubes and transforms into a gaseous phase medium, and the heat exchange efficiency formed between the liquid phase medium and the external air through the finned tubes remains relatively stable, so that To solve the technical problem that the gasification efficiency of the gasifier in the prior art cannot be adjusted, the present invention provides an adjustable spray gasifier group.

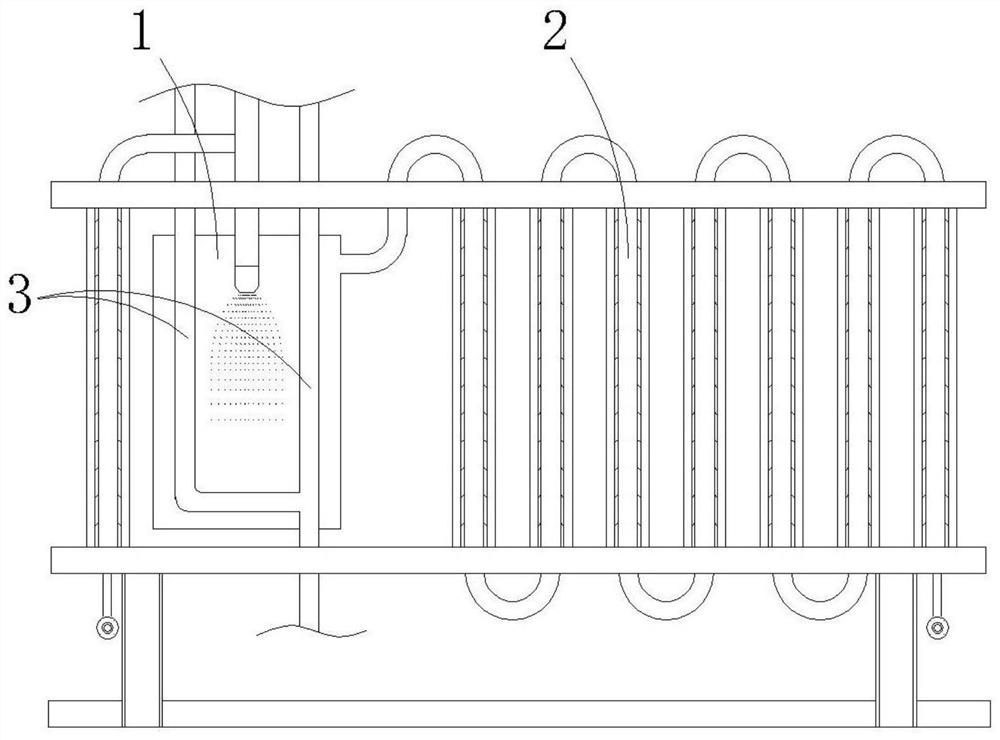

[0026] see figure 1 , an adjustable spray gasifier group, including an atomization device 1, a control device (not shown in the figure), a gasification device 2 and an air temperature device 3;

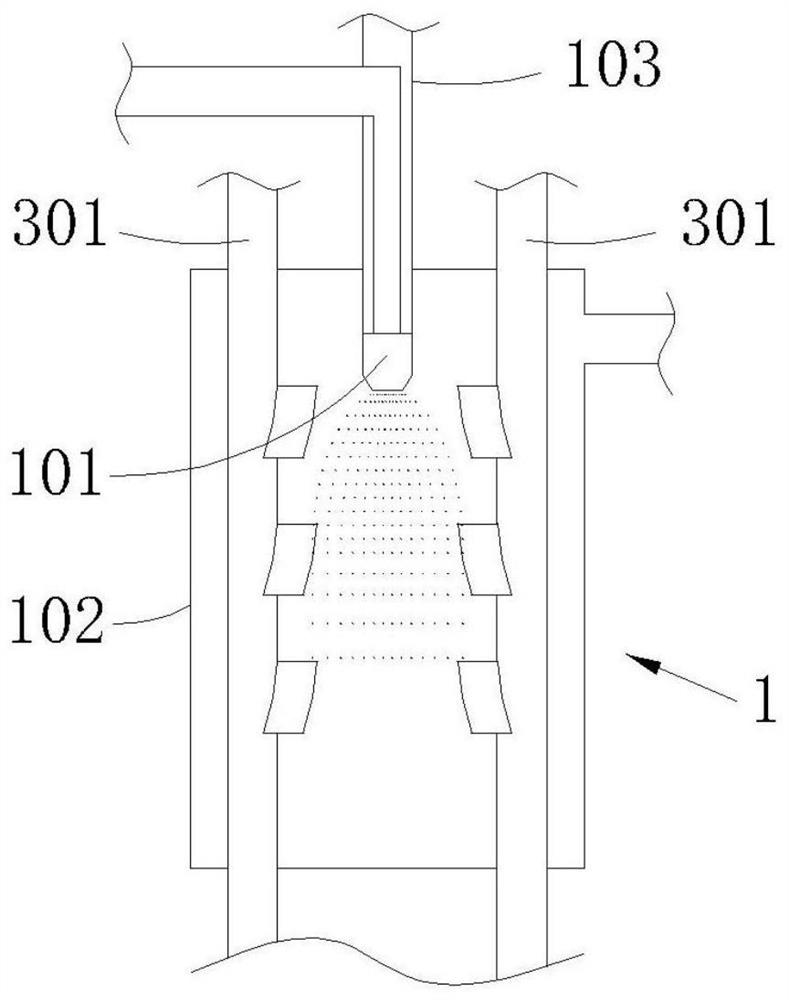

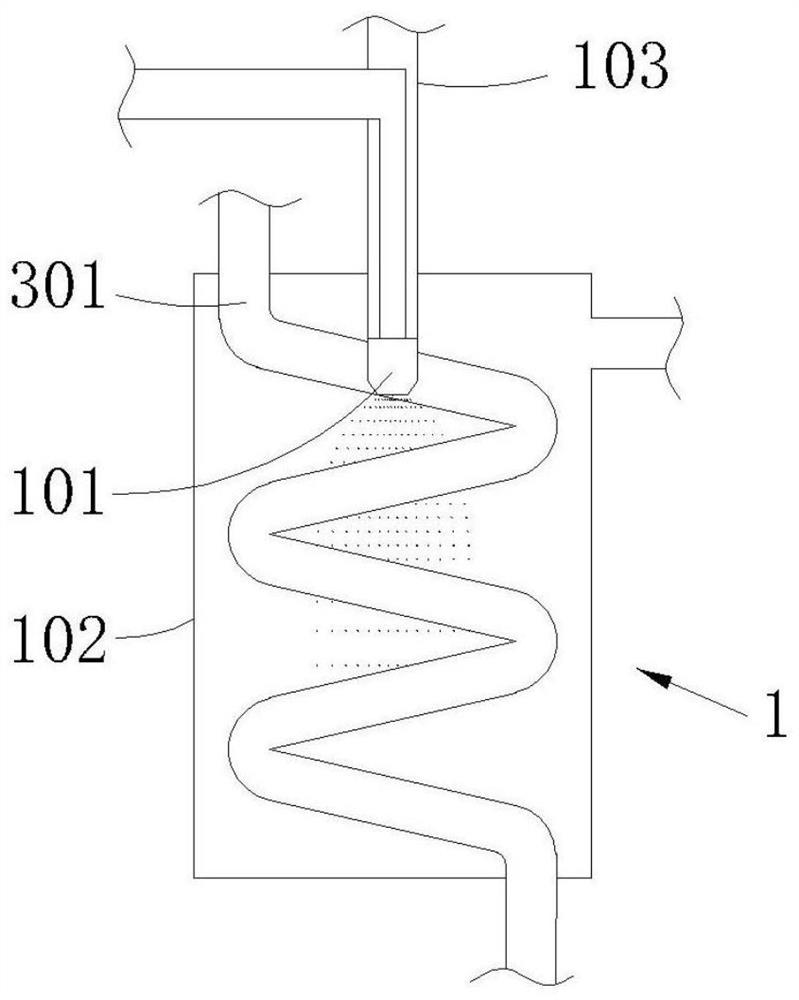

[0027] The atomizing device 1 is used to convert the liquid phase medium into a mist medium, and the mist medium flows irregularly in the atomizing device 1;

[0028] The inner cavity of the air temperature device 3 is filled with a flow medium, and a part of the air t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com