Vibration rod damping sleeve

A technology of vibrating rod and shock-absorbing sleeve, applied in the direction of spring/shock absorber, spring/shock absorber design features, coil spring, etc. effect, the effect of improving the vibrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

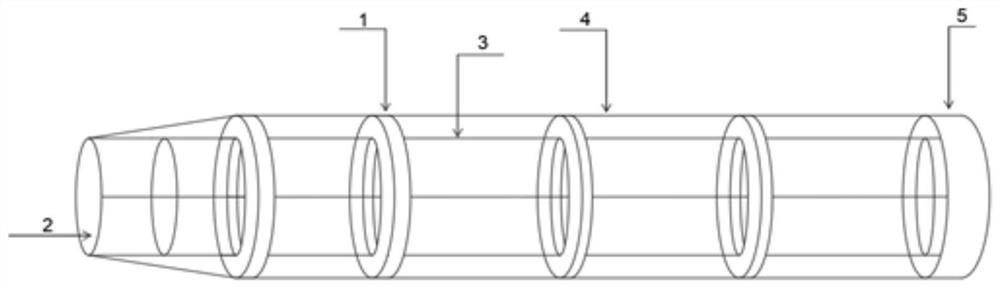

[0018] The technical solution of the present invention is: a vibrating rod shock-absorbing sleeve, such as figure 1 As shown, including a sleeve body 4, at least one shock absorbing assembly is arranged close to the inner wall of the sleeve body 4, the front end of the sleeve body 4 is provided with an opening 2 for the insertion of the vibrating rod 3, and the opening 2 and the tail end of the sleeve body 4 are provided There is a clamping assembly 5 for fixing the sleeve body 4 and the vibrating rod 3 .

[0019] Further, the shock absorbing assembly is sheathed on the outer wall of the vibrating rod 3 .

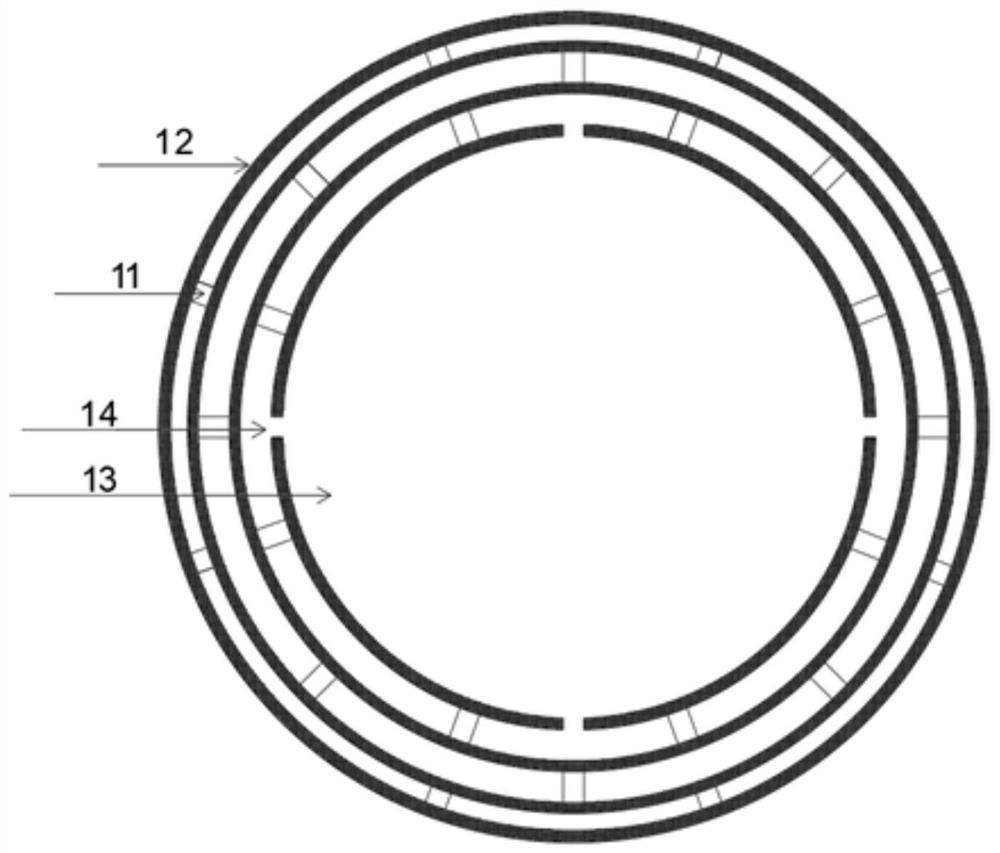

[0020] Furthermore, the shock absorbing assembly is a circular shock absorbing ring 1, such as figure 2 As shown, the circular damping ring 1 includes at least two coaxially arranged hard fixed rings 12 whose diameters gradually increase, and at least two elastic elements are equidistantly arranged between each hard fixed ring 12 11. The elastic element 11 has good elast...

Embodiment 2

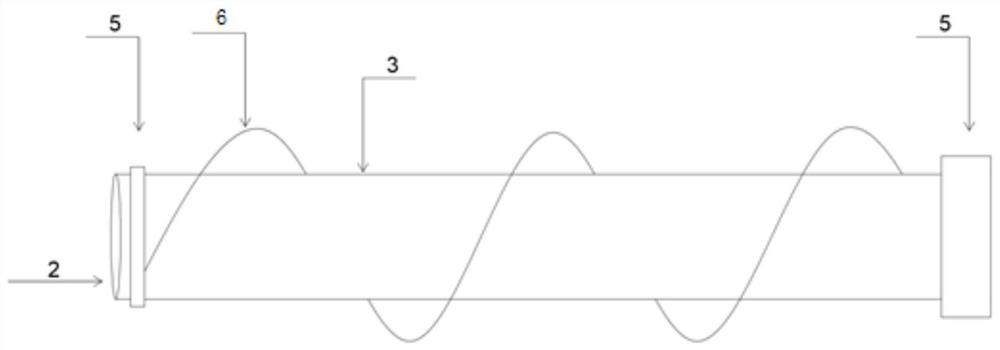

[0024] The technical solution of the present invention is: a vibrating rod shock-absorbing sleeve, including a sleeve body 4, at least one shock-absorbing component is arranged close to the inner wall of the sleeve body 4, and the front end of the sleeve body 4 is provided with an opening for the insertion of the vibrating rod 3 2. The opening 2 and the tail end of the casing 4 are provided with a clamping assembly 5 .

[0025] Further, the shock absorbing assembly is sheathed on the outer wall of the vibrating rod 3 .

[0026] Furthermore, the shock absorbing assembly is a spiral shock absorbing ring 6, such as image 3 As shown, the helical shock absorbing ring 6 is a hard shock absorbing ring spirally wound on the outer wall of the vibrating rod 3, and the hard shock absorbing ring includes at least two coaxially arranged For large hard strips, a plurality of elastic elements 11 are equidistantly arranged in the circumferential direction between each hard strip, and each h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com