Torsional vibration isolator

A technology of isolators and elastic components, applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve the problems of reducing car ride comfort, uneven ignition, noise and vibration, etc., to improve ride comfort , Good shock absorption effect, the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

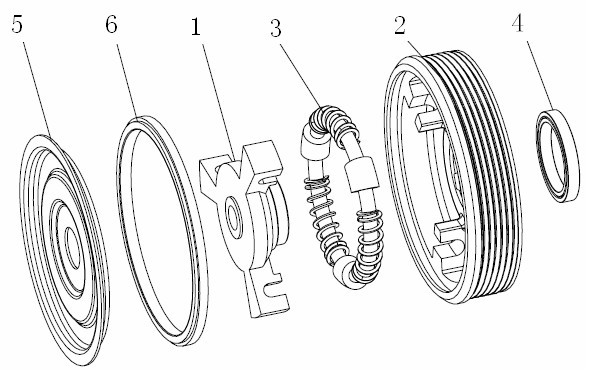

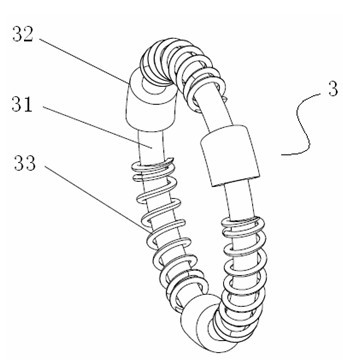

[0022] Such as Figure 1-5 As shown, the torsional vibration isolator of the present invention in this embodiment includes a driving disk 1, a driven disk hub 2 and an elastic damping unit 3, and the elastic damping unit 3 consists of a circular guide rail 31 and a number of evenly distributed on the guide rail 31 It consists of elastic parts; the middle part of the driving disc 1 is provided with a convex part 11, and the middle part of the convex part 11 is provided with a through hole 12. The outer periphery of the convex part 11 is press-fitted with a bearing 4, and the driving disc 1 is evenly distributed with three shift forks 13. The same side of the fork 13 is provided with a first groove 14; the number and position of the driven hub 2 are provided with ribs 21 corresponding to the shift fork 13, and the ribs 21 are all provided with a second groove 22 , the direction of the first groove 14 is opposite to that of the second groove 22; the outer circumference of the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com