Impeller, fan and extractor hood

A technology of impellers and blades, applied in the field of power equipment, can solve the problems of high noise reduction cost and complicated processing technology of impellers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

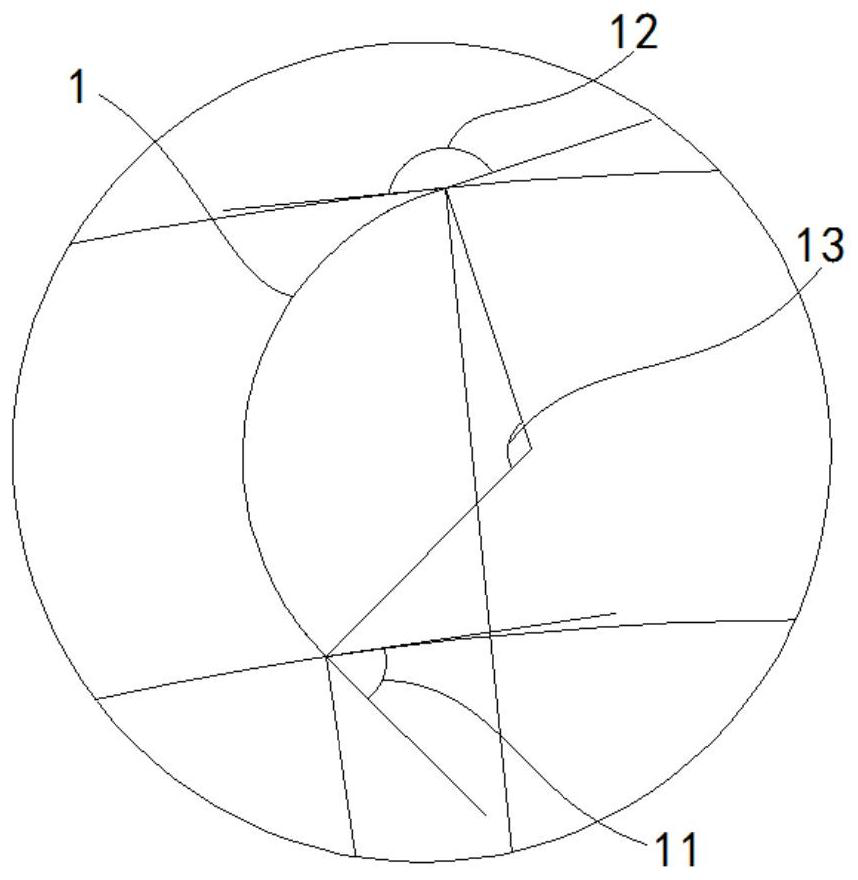

[0039] The impeller provided in this embodiment, such as Figure 1 to Figure 5 As shown, a plurality of blades 1 are included, and the plurality of blades 1 are arranged at intervals along the circumference of the impeller; the curved line of each blade 1 is a Bezier curve; a flow channel is formed between two adjacent blades 1, along the In the radial direction of the impeller, the cross-sectional area of the flow channel gradually decreases from the flow channel inlet to the flow channel outlet.

[0040] The curved line of the blade 1 is drawn using a Bezier curve, and the shape of the blade 1 is optimized through the Bezier curve. Combined with simulation analysis, compared with the arc blade 1' in the prior art, the inlet angle 11 of the blade 1 is reduced, and The curvature of the blade 1 increases, and in the case of the same outer diameter of the blade 1, the cross section of the flow path of the blade 1 increases, so that the loss of the flow path of the blade 1 is r...

Embodiment 2

[0084] The fan provided by this embodiment includes a volute 6, an air guide ring 8, a motor 7 and the impeller provided in Embodiment 1; the motor 7 and the impeller are arranged inside the volute 6, and the output shaft of the motor 7 is fixedly connected to the impeller, and the guide The wind ring 8 is fixedly connected with the end face of the volute 6 where the air inlet is located.

[0085] Specifically, the output shaft of the motor 7 can be fixedly connected with the flange structure 5 on the middle plate 3 to drive the impeller to rotate.

[0086]The curved line of the blade 1 is drawn using a Bezier curve, and the shape of the blade 1 is optimized through the Bezier curve. Combined with simulation analysis, compared with the arc blade 1' in the prior art, the inlet angle 11 of the blade 1 is reduced, and The curvature of the blade 1 increases, and in the case of the same outer diameter of the blade 1, the cross section of the flow path of the blade 1 increases, so t...

Embodiment 3

[0088] The range hood provided in this embodiment, such as Figure 6 As shown, the impeller provided by Embodiment 1 or the fan provided by Embodiment 2 are included. The curved line of the blade 1 is drawn using a Bezier curve, and the shape of the blade 1 is optimized through the Bezier curve. Combined with simulation analysis, compared with the arc blade 1' in the prior art, the inlet angle 11 of the blade 1 is reduced, and The curvature of the blade 1 increases, and in the case of the same outer diameter of the blade 1, the cross section of the flow path of the blade 1 increases, so that the loss of the flow path of the blade 1 is reduced. The blade 1 can reduce the vortex and flow separation at the inlet of the blade 1, so that the air inlet flow is smooth, and the separation phenomenon of the air flow at the outlet of the blade 1 is also reduced to a certain extent, and the efficiency of the fan is basically not lost. While ensuring the performance, improving the flow f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com