Wall explosion-proof reinforcing module, explosion-proof wall and preparation methods of wall explosion-proof reinforcing module and explosion-proof wall

A wall and liquid technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of increasing wall load-bearing, high surface density, wall damage, etc., to improve absorption, reduce direct collision, and reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below with reference to the accompanying drawings and examples.

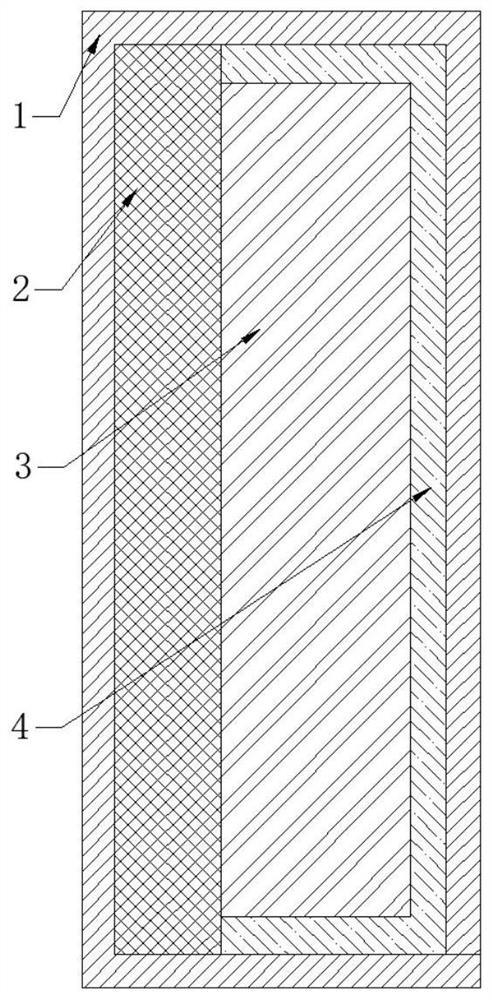

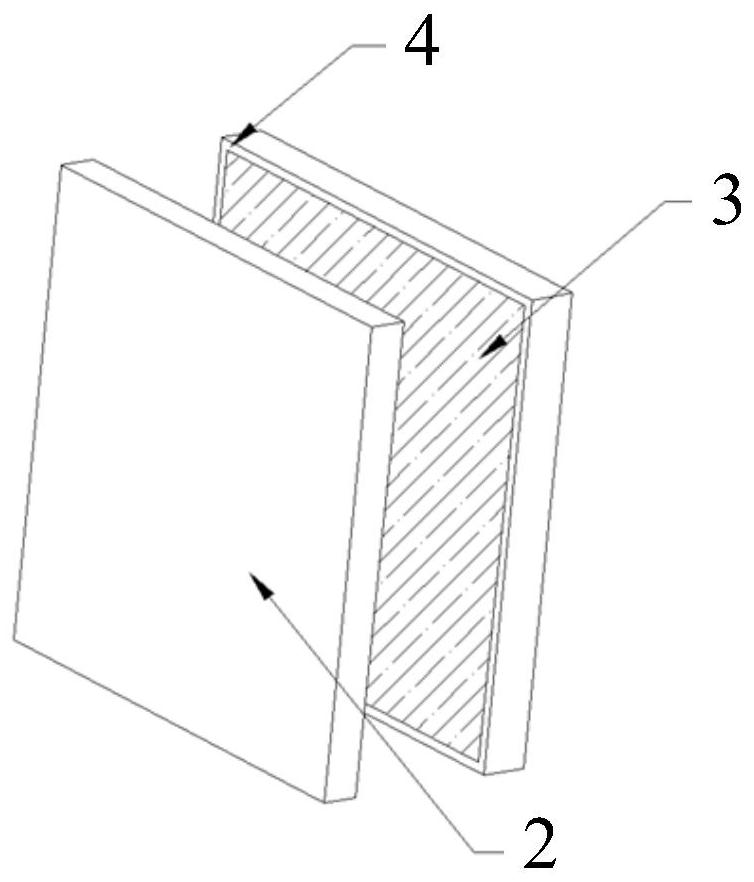

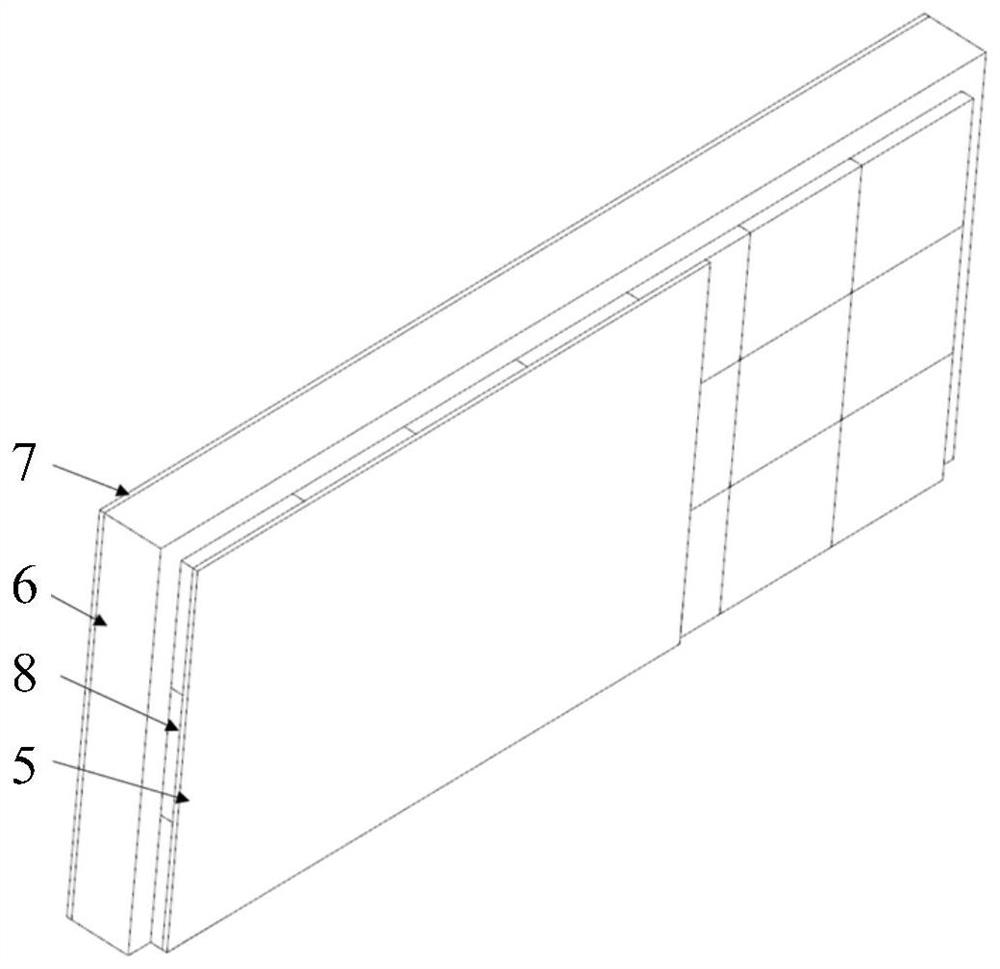

[0045] The invention provides a wall explosion-proof enhanced module, such as figure 1 and figure 2 As shown, the wall explosion-proof reinforcement module 8 includes an outer shell 1, and an inner protective structure wrapped in the outer shell 1, the inner protective structure includes a foam layer 2, a liquid protective layer 3 and an elastomer layer 4, the The foam layer 2, the liquid protection layer 3 and the elastomer layer 4 are sequentially arranged along the explosion-facing surface.

[0046] Wherein, the outer shell layer 1 is mainly used for connecting walls, and provides certain support for the internal protective structure, forms a modular structure, and has a certain shock wave absorption capacity. The shell layer 1 can be made of foamed cement with a density of 300-800kg / m 3 , the wall thickness is 5-15mm.

[0047] The foam layer 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com