Novel plantain core fiber non-woven fabric and preparation method thereof

A non-woven fabric, plantain technology, applied in the field of new plantain core fiber non-woven fabric and its preparation, can solve the problems of easy growth of mold and bacterial propagules, can not be used excessively for a long time, poor strength and durability, etc., and achieves good biological reproducibility. Good degradability, strength and durability, and strong antibacterial and bactericidal functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

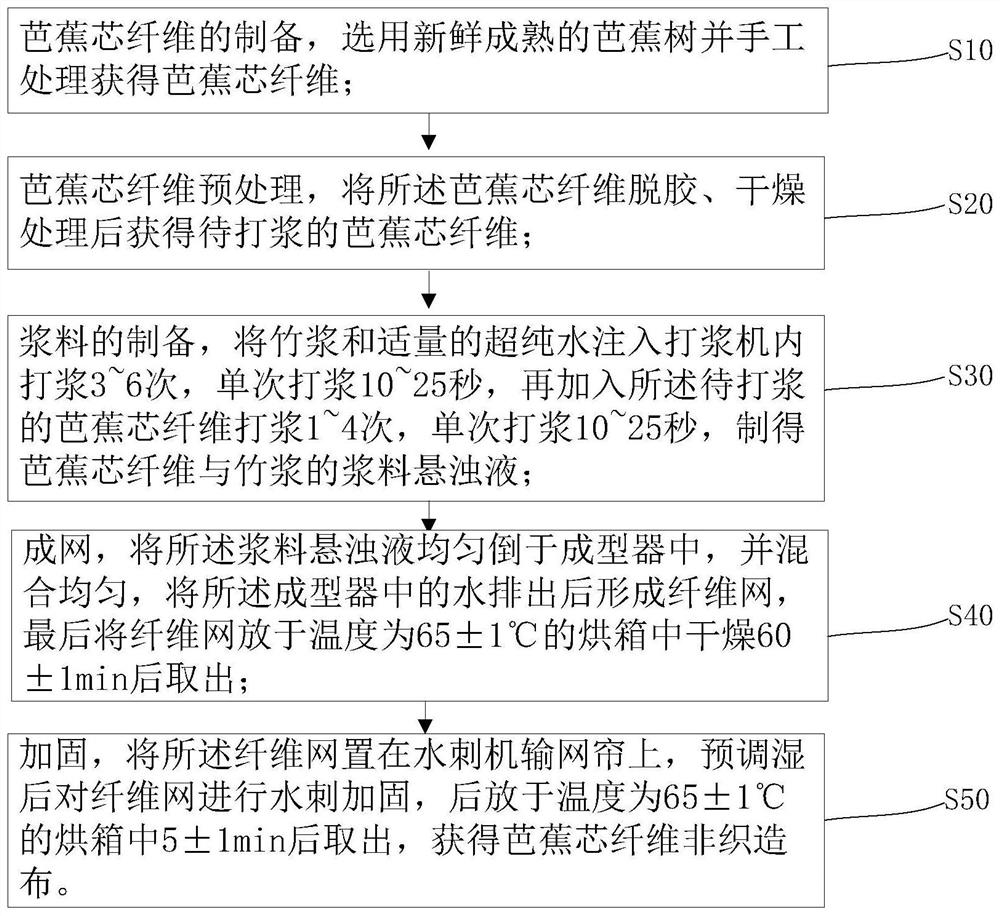

[0023] The present embodiment provides a kind of preparation method of novel plantain core fiber nonwoven fabric, such as figure 1 As shown, the following steps are included: preparation of S10 plantain core fiber, selecting fresh and mature plantain trees and manually processing to obtain plantain core fiber. S20 Pretreatment of plantain core fibers, degumming and drying the plantain core fibers to obtain plantain core fibers to be beaten. Preparation of S30 slurry, injecting bamboo pulp and appropriate amount of ultrapure water into the beater for 3-6 times for beating for 10-25 seconds each time, then adding the plantain core fiber to be beaten for 1-4 times for beating for a single time beat for 10-25 seconds each time to obtain a slurry suspension of plantain core fiber and bamboo pulp. S40 forming a web, pour the slurry suspension evenly into the former, and mix evenly, drain the water in the former to form a fiber web, and finally put the fiber web in a room with a tem...

Embodiment 1

[0029]S11 Collect fresh and mature banana trees, peel off the outer pseudostem to obtain the core of the banana stem, wash with clean water, and drain the surface water.

[0030] S12 Use a knife to place the plantain core at a distance of 2 cm from one end, and gently draw a circle on the bast part perpendicular to the axial direction of the plantain core.

[0031] S13 quickly breaks off the incision, and slowly pulls it to both sides at a uniform speed to obtain the plantain core fiber.

[0032] S21 alkali treatment, alkali treatment of the plantain core fiber in a sodium hydroxide solution with a temperature of 80° C. and a mass concentration of 10 g / L for 2.5 hours, and washing at 40° C. for several times before use.

[0033] S22 Acid treatment: acid-treat the alkali-treated plantain core fibers in a sulfuric acid solution with a mass concentration of 0.3 g / L for 10 minutes, wash with water several times at 40° C., and dry in an oven at 75° C. for 2.5 hours to obtain planta...

Embodiment 2

[0038] S11 Collect fresh and mature banana trees, peel off the outer pseudostem to obtain the core of the banana stem, wash with clean water, and drain the surface water.

[0039] S12 Use a knife to place the plantain core at a distance of 2 cm from one end, and gently draw a circle on the bast part perpendicular to the axial direction of the plantain core.

[0040] S13 quickly breaks off the incision, and slowly pulls it to both sides at a uniform speed to obtain the plantain core fiber.

[0041] S21 Alkali treatment, the plantain core fiber is treated with alkali in a sodium hydroxide solution with a temperature of 90° C. and a mass concentration of 12 g / L for 3 hours, washed with water at 40° C. for several times, and then used.

[0042] S22 Acid treatment: acid-treat the alkali-treated plantain core fibers in a sulfuric acid solution with a mass concentration of 0.5 g / L for 15 minutes, wash with water several times at 40° C., and dry in an oven at 75° C. for 2.5 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com