Double-component melt-blown spinneret plate for producing skin-core structure spinning

A skin-core structure, two-component technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problem that the spinneret does not meet the production of skin-core structure spinning, etc., to achieve difficult mixing, injection The effect of fast material and diversion, guaranteed quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

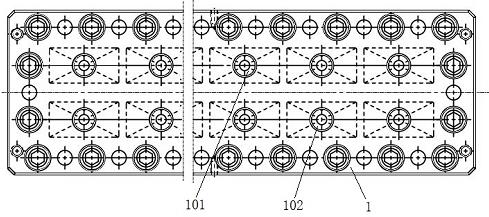

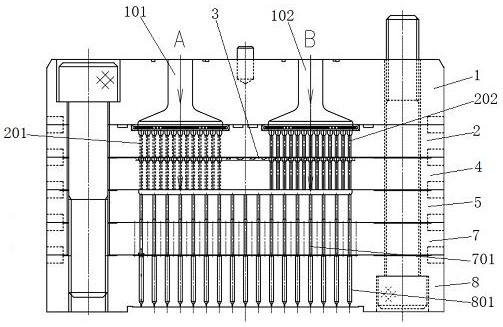

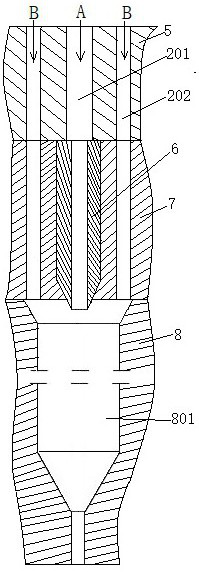

[0023] Such as figure 1 and figure 2 As shown, a two-component melt-blown spinneret for producing skin-core structure spinning includes an upper feed plate 1, and the surface of the upper feed plate 1 is evenly opened with several groups of feed ports, and several feed ports include A component port 101 and B component port 102, a lower feed plate 2 is installed below the upper feed plate 1, and several A component guides are opened on the lower feed plate 2 at the A component port 101. Orifices 201, the lower feed plate 2 is located at the A component port 101 and has a number of B component diversion holes 202, the A component diversion holes 201 and B component diversion holes 202 run through the lower The material plate 2, the upper distribution plate 4 and the lower distribution plate 5 are installed in sequence below the lower feeding plate 2, and several groups of the A component flow diversion holes 201 and the B component flow diversion holes 202 pass through the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com