Paper box with automatic lock bottom and tuck cover on single cardboard and forming method thereof

A self-buckling and carton technology, used in paper/cardboard containers, papermaking, box making operations, etc., can solve the problems of high raw material cost, high production cost, lack of squareness, etc., to reduce production costs, reduce transportation costs, The effect of reducing the amount of raw materials used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

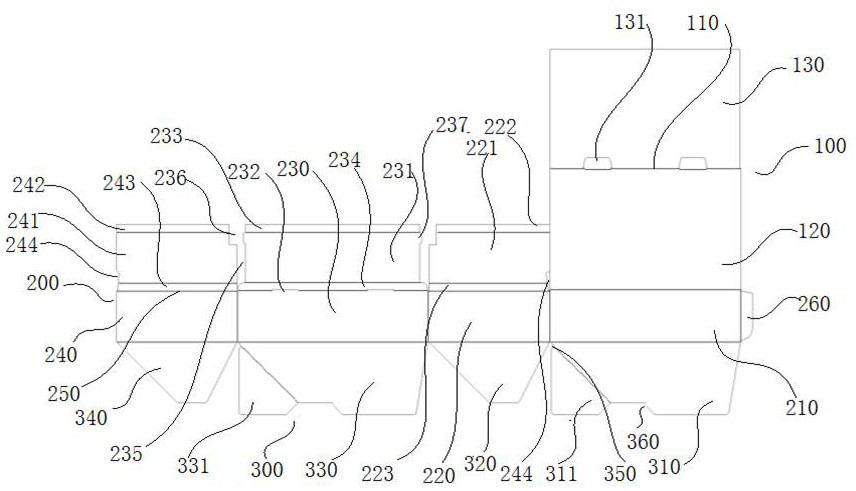

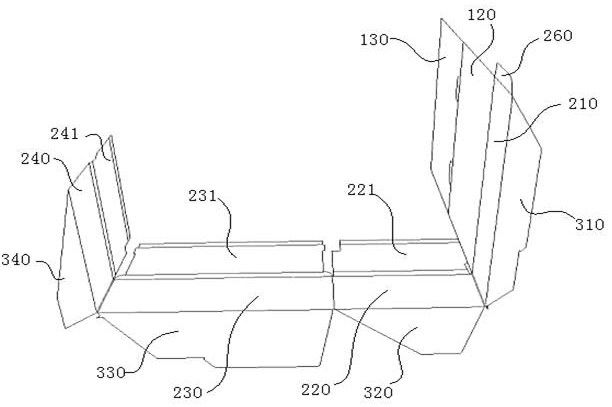

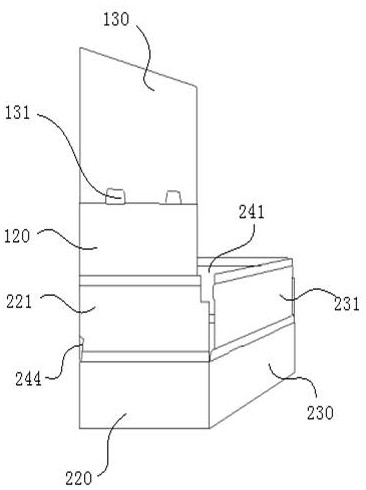

[0034] Such as Figure 1 to Figure 5 Shown is an embodiment of the self-closing bottom flap carton for single-fed cardboard of the present invention, comprising a flap 100, a skirt 200 and a self-closing bottom 300, the skirt 200 including a first side 210, a second side connected end to end. Side 220, third side 230 and fourth side 240, one side of the flap 100 is connected to the first side 210, the other side of the flap 100 is engaged with the third side 230; the first side 210, the second side 220 , the third side 230 and the fourth side 240 are respectively connected with the first button bottom 310, the second button bottom 320, the third button bottom 330 and the fourth button bottom 340, the first button bottom 310, the second button bottom 320, the second button bottom The three buckle bottom 330 and the fourth buckle bottom 340 can overlap each other to form the self-buckle bottom 300 .

[0035] When this embodiment is implemented, it combines the advantages of the...

Embodiment 2

[0046] This embodiment is an embodiment of the forming method of the single cardboard self-closing bottom rocking cover carton in the first embodiment.

[0047] S10. Die-cut the jammed paper according to the pre-designed size and shape to obtain the paper to be formed;

[0048] S20. Transfer the paper to be formed in step S10 to the squeegee area for gluing, bond the glued surface 260 and the fourth side 240, and fold the first side 210 and the second side 220 in half, and the third side 230 and the fourth side 240 folds on four sides and then plane stacking and transportation;

[0049] S30. The paper stacked on the plane in step S20 is transported to the client or the production end, and the first side 210, the second side 220, the third side 230 and the fourth side 240 are opened, and the first button bottom 310 and the second button at the bottom are The bottom 320, the third buckle bottom 330 and the fourth buckle bottom 340 are automatically buckled;

[0050] S40. Foldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com