Efficient juncus effuses cleaning technology

A rush, high-efficiency technology used in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., to prevent clutter, tangle, knot or break, and achieve good cleaning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

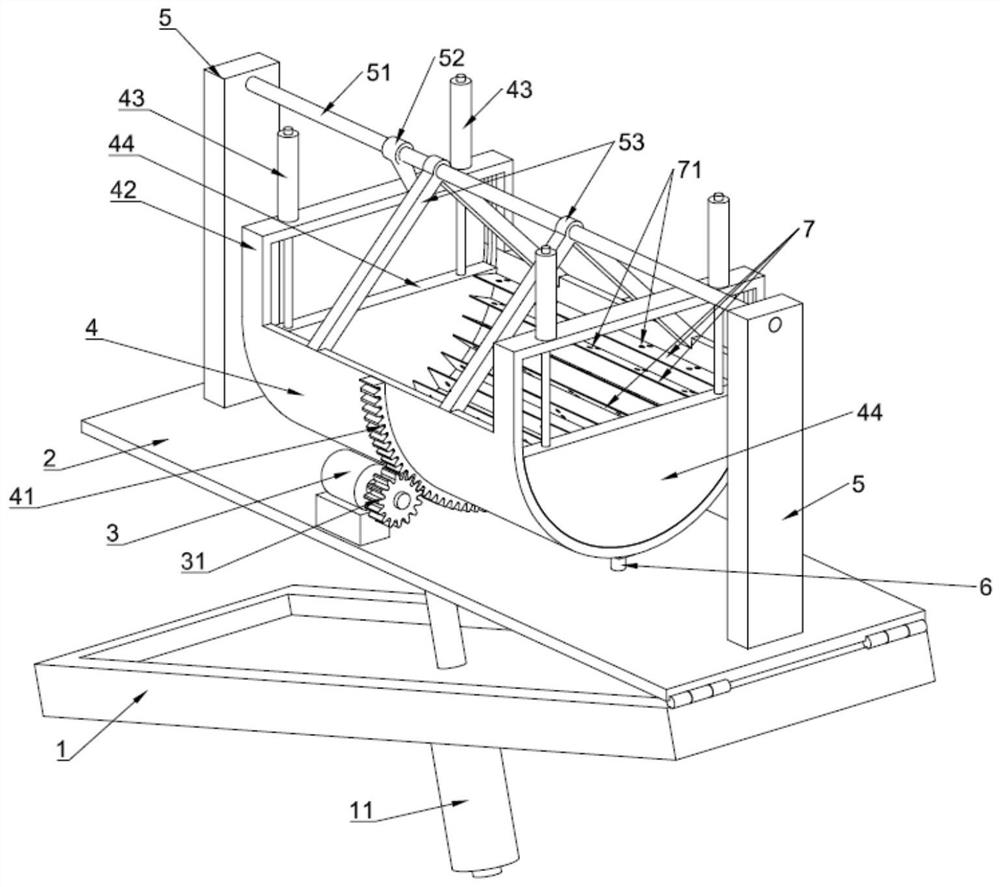

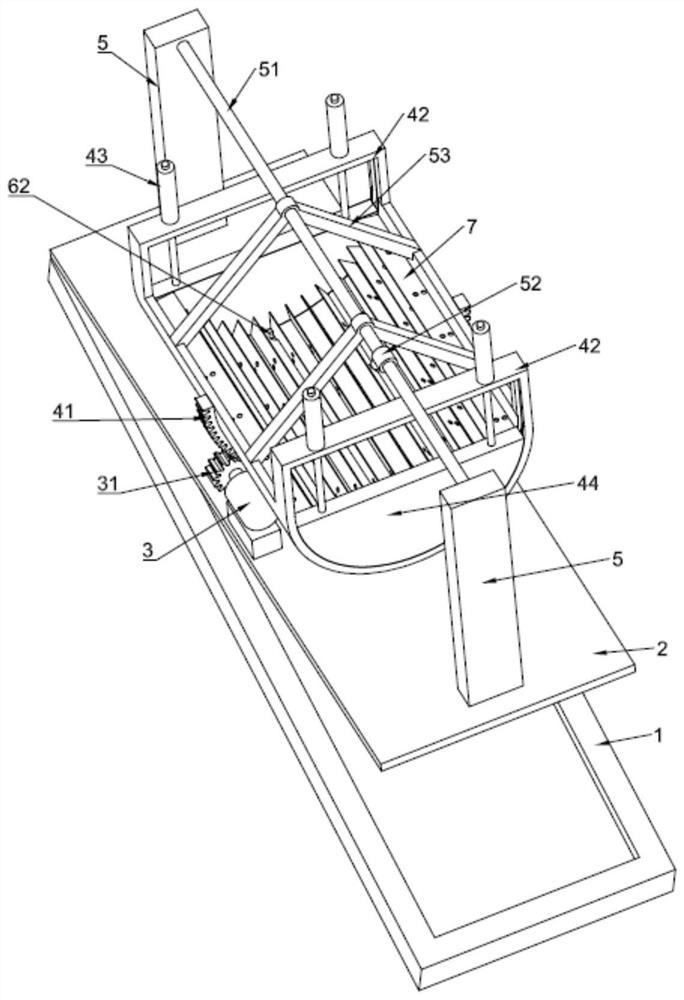

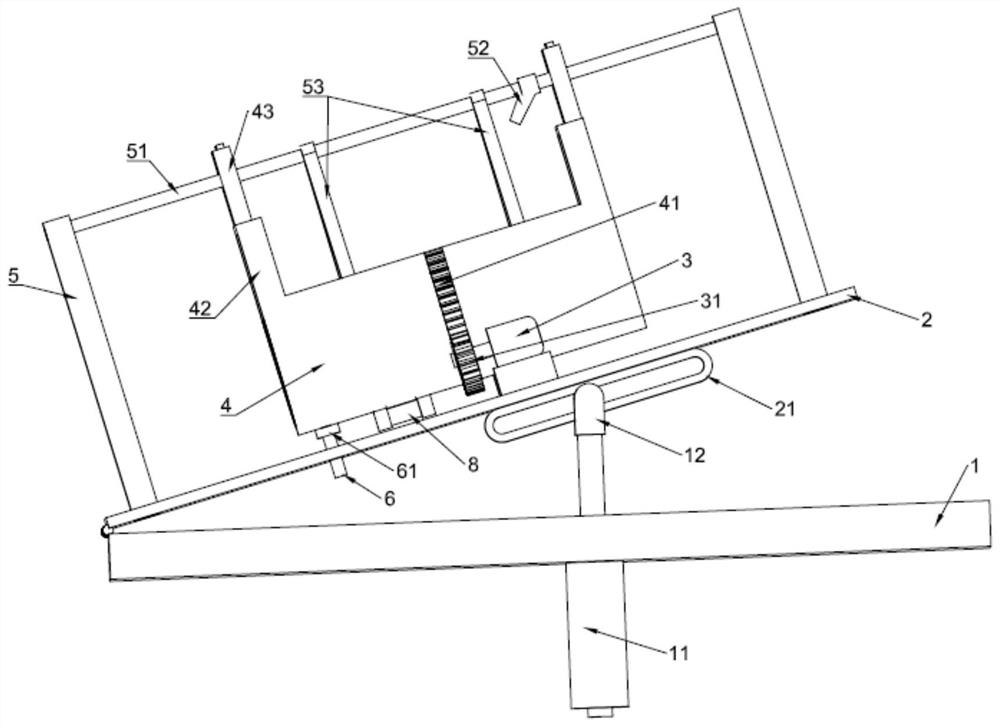

Image

Examples

Embodiment 1

[0025] Embodiment 1: clean rush rush as follows:

[0026] Rush efficient cleaning process, the specific steps are as follows:

[0027] (a) Swing and clean the freshly harvested rush three times with a swing cleaning device;

[0028] (b) For the first cleaning, use flour suspension with a concentration of 100g / L to soak for 30 minutes, the ratio of solid to liquid is 1g: 100g, then swing back and forth to clean for 15 minutes, and then drain the flour solution; the frequency of swing cleaning is 10 times / min, when soaking, the liquid does not pass through the partition. .

[0029] (c) Swing and clean for 20 minutes while spraying clean water for the second time, and discharge the cleaning waste liquid at the same time until there are no visible flour particles on the surface of the rushes;

[0030] (d) For the third cleaning, use single-distilled water to swing and soak for 15 minutes, and the ratio of solid to liquid is 1g:100g. After the single-distilled water is drained,...

Embodiment 1

[0037] Comparative Example 1: the rest are the same as in Example 1, the difference is that the rushes are cleaned directly by a turbine-type agitation cleaning method instead of using a swing cleaning device for cleaning.

Embodiment 2

[0038]Comparative Example 2: the rest are the same as in Example 1, the difference is that no swing cleaning device is used for cleaning, and the rushes are cleaned directly by immersion ultrasonic bubble cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com