Cooling cup cover device for thermos cup and thermos cup

A technology of thermos cups and lids, applied in the field of thermos cups, can solve the problems of maintenance, disassembly, troublesome installation, long cooling time, and long time required.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

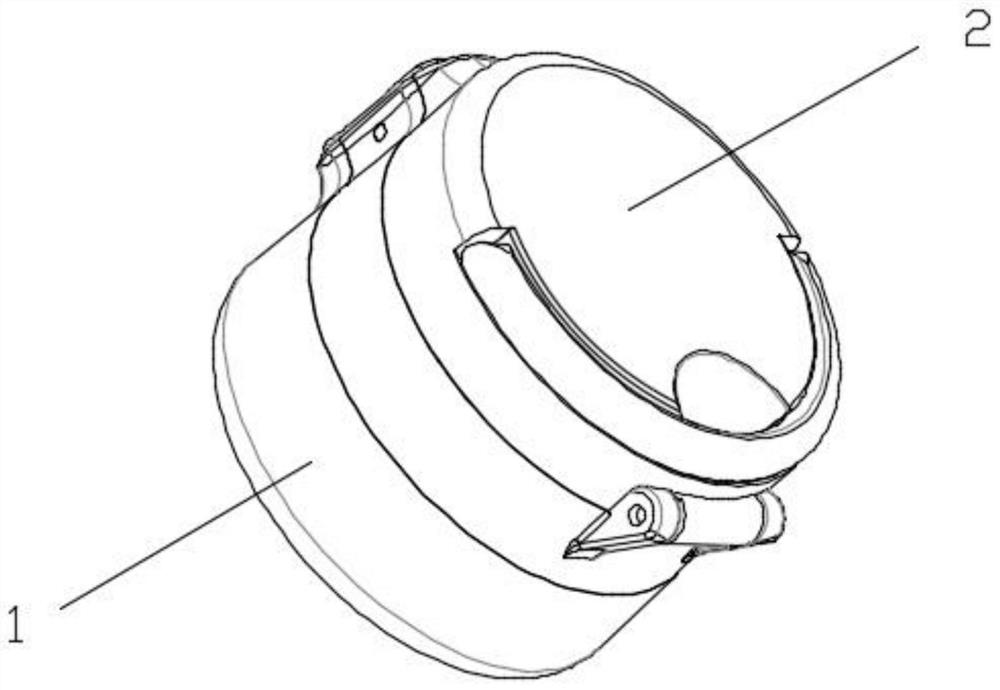

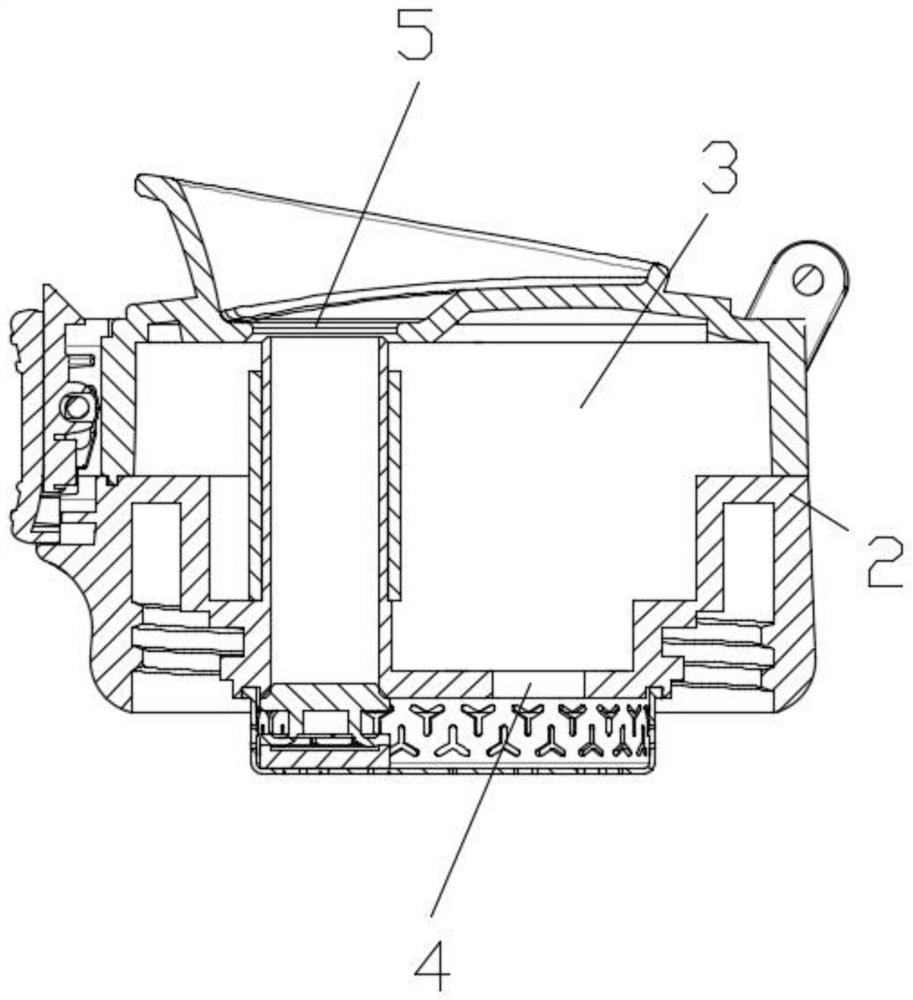

[0031] Embodiment 1: as figure 1 As shown in -2, the cooling cup lid device and the thermos cup used for the thermos cup. After research, the applicant found that the existing thermos cup structure, one is a very common structure on the market, which has a good heat preservation effect, but It is troublesome when drinking, because the temperature of the drinking water stored in it is too high, it is very hot and cannot be used. The common method is to pour the water in the thermos cup on the lid, and then drink it after standing for a while. It is very troublesome and inconvenient. The other is a thermos cup with a rapid cooling function (such as CN201810055877.9 mentioned in the background technology), but it can only be an overall cooling, which will cause problems. The overall cooling The time is relatively long, and it can not meet the needs of users. Therefore, the applicant has developed the technical solution of the present application, which is used for the cooling cup...

Embodiment 2

[0033] Embodiment 2: as image 3 As shown, the cooling cup lid device and the thermos cup used for the thermos cup, after research, the applicant found that the existing thermos cup structure, one is a very common structure on the market, which has a good heat preservation effect, but it is in It is troublesome when drinking, because the temperature of the drinking water stored in it is too high, it is very hot and cannot be used. The common method is to pour the water in the thermos cup on the lid and let it sit for a while before drinking, which is very troublesome. It is also very inconvenient. The other is a thermos cup with a rapid cooling function (such as CN201810055877.9 mentioned in the background technology), but it can only be the overall cooling, which will cause problems. The time for the overall cooling It is relatively long and cannot meet the needs of users. For this reason, the applicant has developed the technical solution of the present application, which is...

Embodiment 3

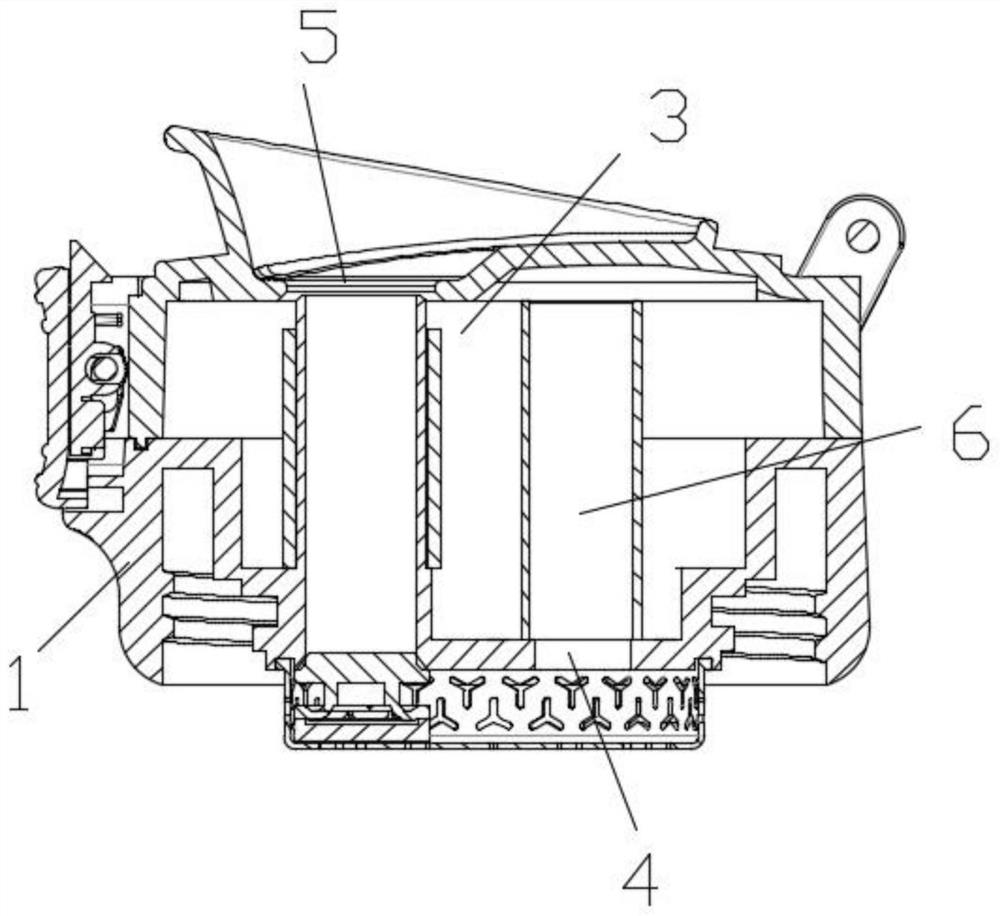

[0035] Embodiment 3, see attached Figure 4The rest are the same as in Example 1, but, in this embodiment, the structure of the liquid inlet check valve 6 is different, specifically as follows, including a guide sleeve 601 communicating with the liquid inlet chamber 4, located in the The passage port 602 on the side wall of the guide sleeve 601 is in clearance fit with the guide sleeve 601 and is used to prevent the backflow of the liquid entering the liquid chamber 3. The sealing slide tube 603, the top surface of the seal slide tube 603 and There is a gap between the top surfaces of the liquid-holding chamber 3, and the generation of this gap is provided with a reinforcing rib plate on the top surface of the solution chamber 3 or an opening is provided on the top surface of the sealing sliding tube 603, and the sealing sliding tube is sleeved on the guide sleeve , can slide, because the side wall of the guide sleeve has a passage port, such a structure makes when the thermos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com