Processing technology of quick-frozen corn

A processing technology, corn technology, applied in the functions of food ingredients, preservation of food ingredients as antimicrobials, preservation of fruits/vegetables by freezing/refrigeration, etc., can solve the problems of corn shrinkage, poor taste, black appearance, etc., Achieve the effect of inhibiting browning, improving product flavor and reducing enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

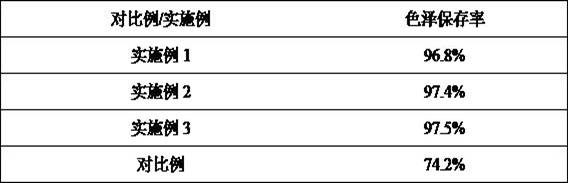

Examples

Embodiment 1

[0018] A method for processing quick-frozen corn kernels, comprising the following steps.

[0019] (1) Cleaning: Soak in 1.5% sodium chloride solution for 25 minutes, then cool with 5°C flowing cold water for 10 minutes.

[0020] (2) Pre-cooking: Pre-cooking in hot water at 80°C for 5 minutes, then cooling in running water at 15°C.

[0021] (3) Steaming: use 98°C hot water to cook for 7 minutes, and cook the corn until 8 minutes.

[0022] (4) Color protection: Blanch the corn in 0.30% citric acid solution at 80°C for 70 seconds, then soak the corn in the color protection solution at 3°C.

[0023] (5) Blow-drying: After picking up and draining the open water, place it in a pre-cooling room at 0°C to cool thoroughly to ensure that the temperature of the fresh ear drops below 5°C, and then blow-dry the surface moisture.

[0024] (6) Quick-frozen packaging: The corn is quick-frozen to ensure that the central temperature of the corn drops below -5°C within 9 minutes, and then the...

Embodiment 2

[0027] A method for processing quick-frozen corn kernels, comprising the following steps.

[0028] (1) Cleaning: Soak in 2% sodium chloride solution for 30 minutes, then cool with 7°C flowing cold water for 15 minutes.

[0029] (2) Pre-cooking: pre-cooking in hot water at 84°C for 5 minutes, then cooling in running water at 20°C.

[0030] (3) Cooking: use 100°C hot water to cook for 10 minutes, and cook the corn until 9 minutes.

[0031] (4) Color protection: Blanch the corn in 0.35% citric acid solution at 80°C for 70 seconds, then soak the corn in the color protection solution at 5°C.

[0032] (5) Blow-drying: After picking up and draining the open water, place it in a pre-cooling room at 0°C to cool thoroughly to ensure that the temperature of the fresh ear drops below 5°C, and then blow-dry the surface moisture.

[0033] (6) Quick-frozen packaging: The corn is quick-frozen to ensure that the central temperature of the corn drops below -5°C within 9 minutes, and then the ...

Embodiment 3

[0036] A method for processing quick-frozen corn kernels, comprising the following steps.

[0037] (1) Cleaning: Soak in 1.7% sodium chloride solution for 27 minutes, then cool with 6°C flowing cold water for 13 minutes.

[0038] (2) Pre-cooking: pre-boil in hot water at 82°C for 5 minutes, and then cool in running water at 17°C.

[0039] (3) Steaming: use 99°C hot water to cook for 8 minutes, and cook the corn until 9 minutes.

[0040] (4) Color protection: Blanch the corn in 0.33% citric acid solution at 80°C for 70 seconds, then soak the corn in 4°C color protection solution.

[0041] (5) Blow-drying: After picking up and draining the open water, place it in a pre-cooling room at 0°C to cool thoroughly to ensure that the temperature of the fresh ear drops below 5°C, and then blow-dry the surface moisture.

[0042] (6) Quick-frozen packaging: The corn is quick-frozen to ensure that the central temperature of the corn drops below -5°C within 9 minutes, and then the finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com