SSD laminated layout structure and design method and device

A technology of structural design and layout, applied in CAD circuit design, computer-aided design, calculation, etc., can solve the problems of compressing product board layout and wiring space, unable to ensure sufficient test board verification, unable to truly restore product board design, etc. , to shorten the development cycle, the design principle is reliable, and the substantive characteristics are highlighted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

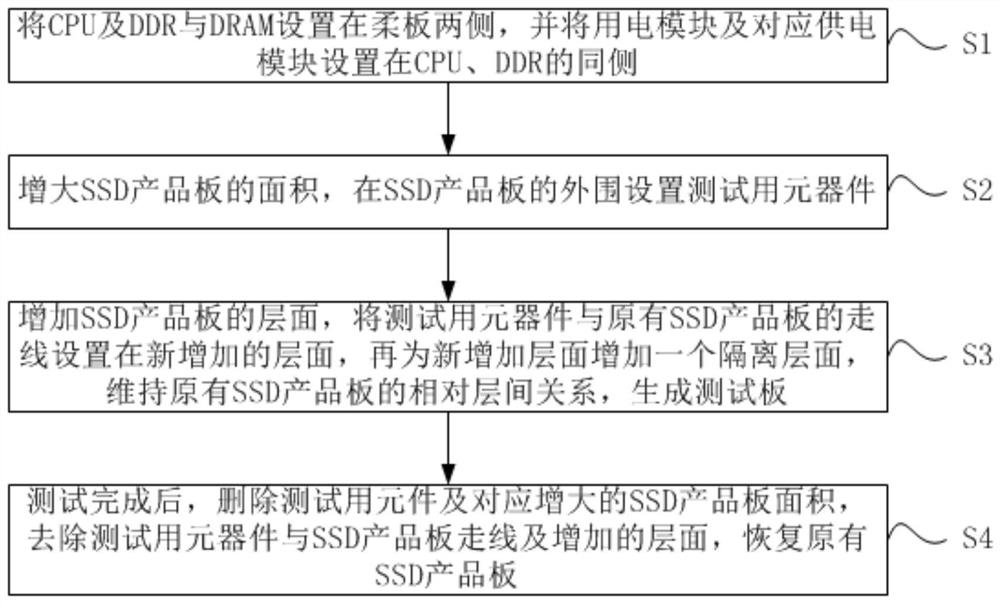

[0075] Such as figure 1 As shown, the present invention provides a method for designing a SSD stack layout structure, comprising the following steps:

[0076] S1. Set the CPU, DDR and DRAM on both sides of the flexible board, and set the power module and the corresponding power supply module on the same side of the CPU and DDR;

[0077] S2. increase the area of the SSD product board, and set the components for testing on the periphery of the SSD product board;

[0078] S3. Increase the level of the SSD product board, set the wiring between the test components and the original SSD product board on the newly added layer, and then add an isolation layer for the newly added layer to maintain the relative interlayer of the original SSD product board relationship, generate a test board;

[0079] S4. After the test is completed, delete the test components and correspondingly increased SSD product board area, remove the test components and SSD product board wiring and the increase...

Embodiment 2

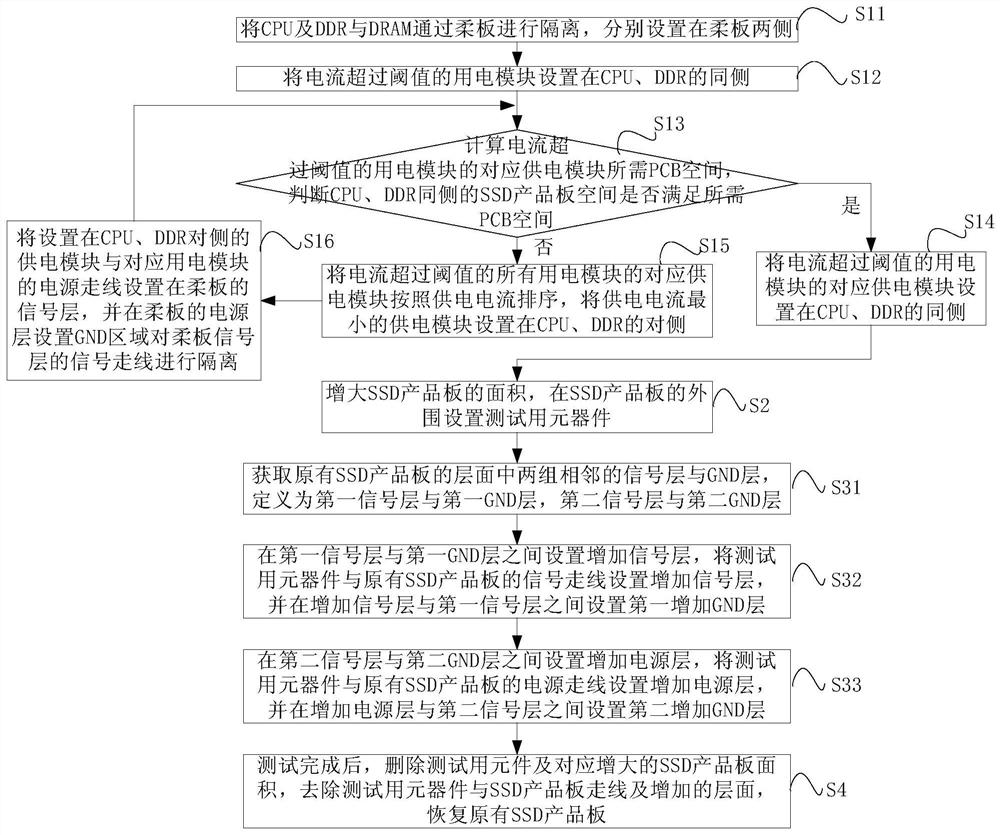

[0081] Such as figure 2 As shown, the present invention provides a method for designing a SSD stack layout structure, comprising the following steps:

[0082] S1. Set the CPU, DDR, and DRAM on both sides of the flexible board, and set the power module and the corresponding power supply module on the same side of the CPU and DDR; the specific steps are as follows:

[0083] S11. Isolate the CPU, DDR and DRAM through the flexible board, and set them on both sides of the flexible board;

[0084] S12. Set the power consumption module whose current exceeds the threshold on the same side of the CPU and DDR;

[0085] S13. Calculate the PCB space required by the corresponding power supply module of the power consumption module whose current exceeds the threshold, and judge whether the SSD product board space on the same side as the CPU and DDR meets the required PCB space;

[0086] If yes, go to step S14;

[0087] If not, go to step S15;

[0088] S14. Set the corresponding power s...

Embodiment 3

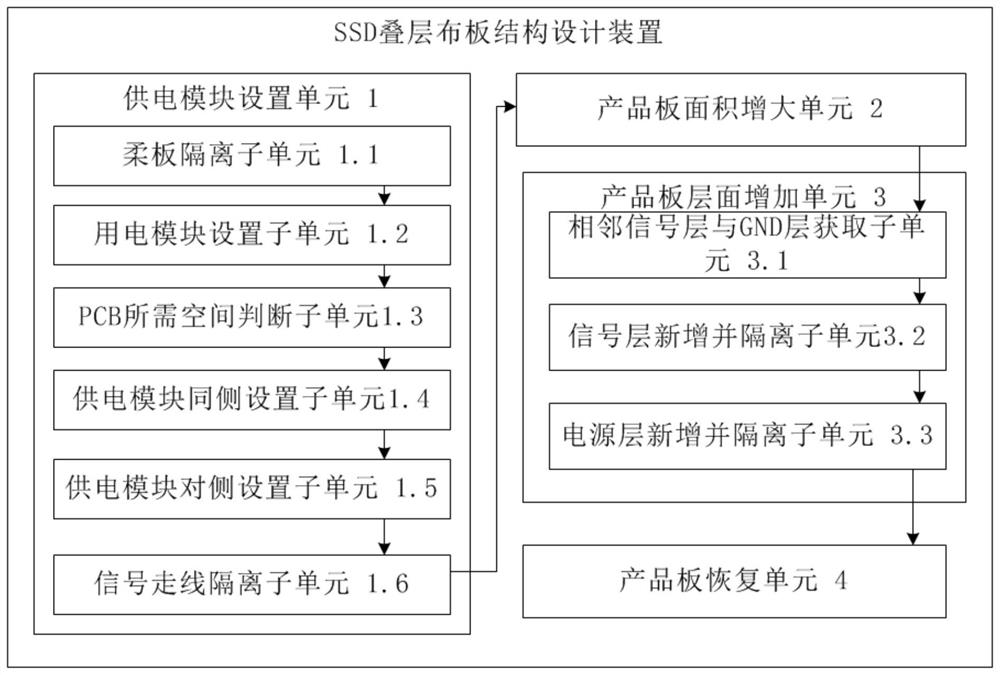

[0101] The present invention provides an SSD stacked layout structure, including an original wiring layer and a newly added wiring layer;

[0102] The original wiring layer includes the SSD product board area and the test area; the test area is set on the periphery of the SSD product board area, and the test area is provided with test components;

[0103] The SSD product board area includes a flex board, and the flex board divides the SSD product board area into a first area and a second area, the first area is provided with DRAM, and the second area is provided with CPU, DRAM, power module and first power supply module; The first power supply module is connected to the CPU, the DRAM and the power consumption module;

[0104] The newly added wiring layer includes a functional layer and an isolation layer, and the functional layer and the isolation layer are arranged adjacent to each other;

[0105] The traces of the test components and the components in the SSD product board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com