Tunnel boring machine cutter fastening state real-time monitoring method

A real-time monitoring and roadheader technology, applied in measuring devices, earthwork drilling, force/torque/work measuring instruments, etc., can solve problems affecting construction progress and efficiency, and achieve the effect of solving the problem of real-time monitoring of tightening conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0033] The invention provides a method for real-time monitoring of the fastening state of the cutting tool of the roadheader, aiming at the problem that the existing shutdown inspection tool fastening state affects the construction progress and efficiency.

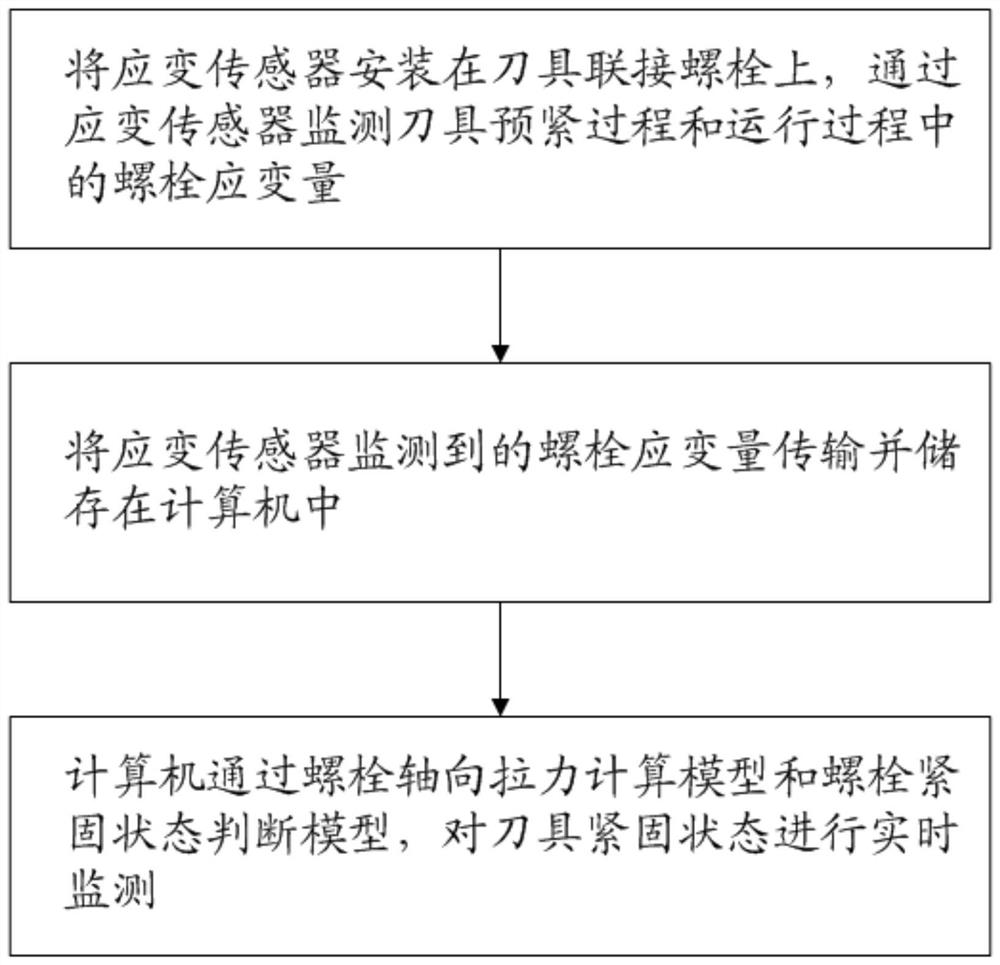

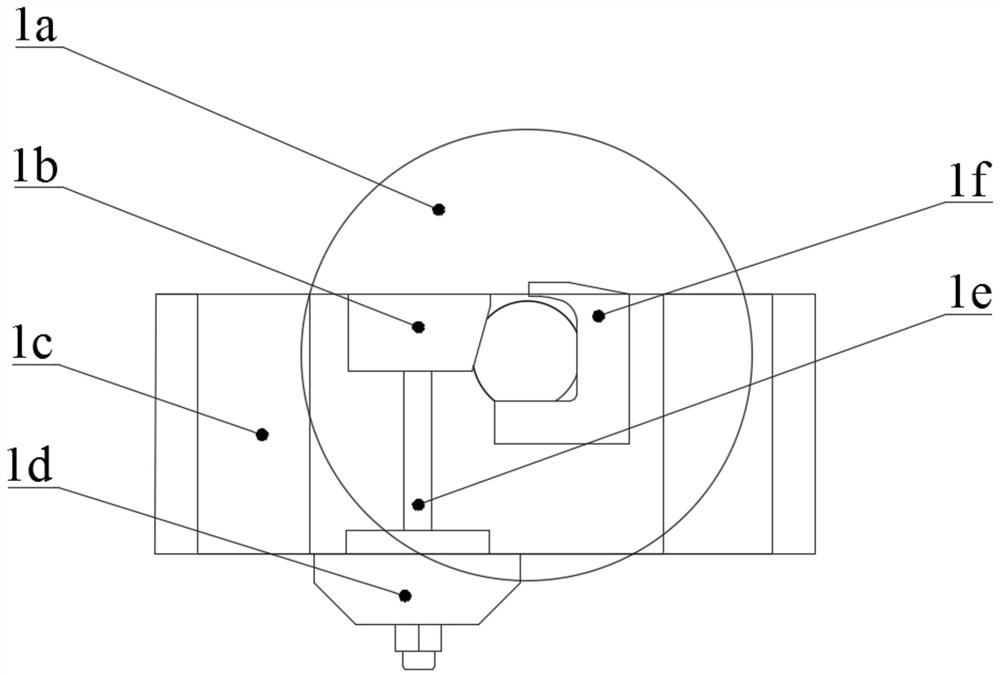

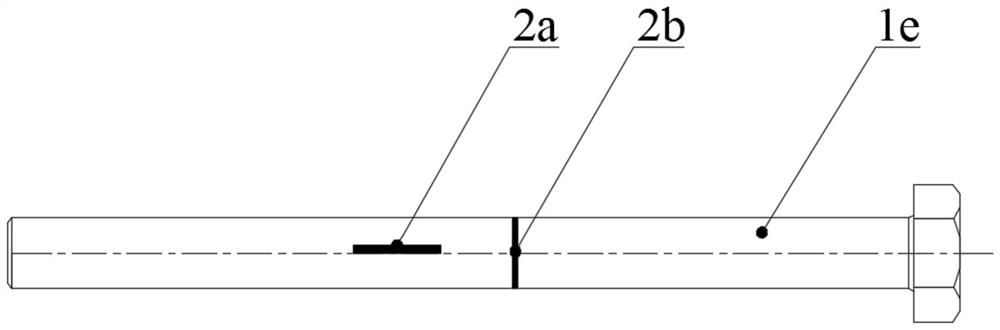

[0034] Such as figure 1 As shown, the embodiment of the present invention provides a method for real-time monitoring of the fastening state of the cutting tool of the roadheader, including: step 1, installing the strain sensor on the connecting bolt of the cutting tool, and monitoring the pre-tightening process of the cutting tool and the tension during the running process through the strain sensor. Bolt strain; step 2, the bolt strain monitored by the strain sensor is transmitted and stored in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com