Unmanned system of crushed aggregate crown block

A technology of cranes and crushed materials, which is applied in the field of unmanned system of crushed cranes, which can solve the problems of complex stockyards, low working efficiency of stockyards, and inability to concentrate human energy for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

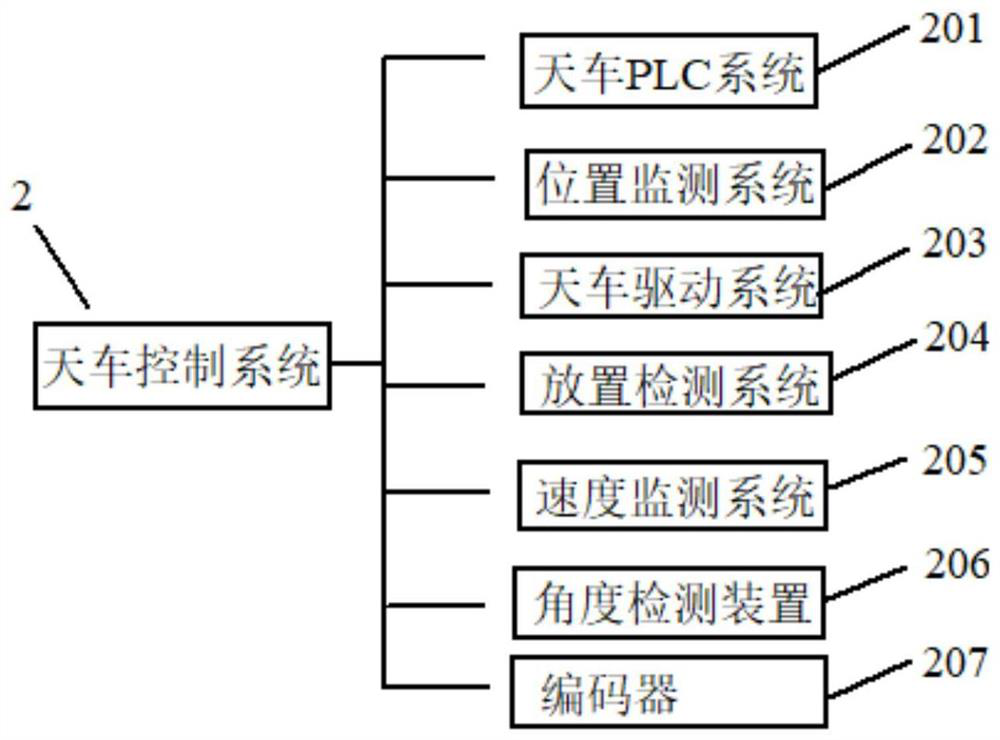

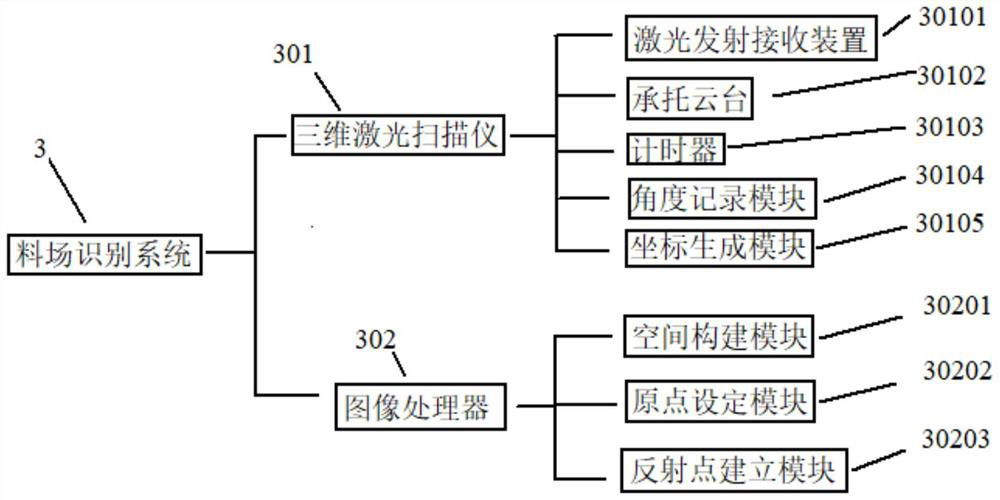

[0048] An unmanned crane system for crushed materials, the system includes: an information management system 1 for processing and managing data of unmanned cranes. It is connected with the information management system 1 and is used to control the crane control system 2 for controlling the mechanical device of the crane to carry out the crushing work. Connected with the information management system 1, it is a stockyard identification system 3 used to collect stockyard material stacking information. Connected with the information management system 1, it is a video monitoring system 4 for monitoring the working status of the stockyard device. It is connected with the information management system 1 and is used to identify the safety management and control system 5 of the position of the personnel in the working area. A power control system 6 for providing a regulated power supply.

Embodiment 2

[0050] Embodiment 1 is repeated, except that the information management system 1 includes: a data processing system 101 for processing data information. Connected to said data processing system 101 is a communication system 102 for linking external and internal data. Connected with the data processing system 101, an execution database 103 for storing working data of the unmanned crane. A job order management system 104 connected to the data processing system 101 for managing job orders. A display system 105 connected to the data processing system 101 for displaying job information.

Embodiment 3

[0052] Embodiment 2 is repeated, except that the communication system 102 includes: an external data bus 10201 for connecting the data interface of the physical device of the unmanned crane. The internal data bus 10202 used to connect the data processor and data storage in the unmanned crane information management system 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com