Chain ring strength detection device for anchor chain production, and use method thereof

A technology of strength detection and chain link, applied in the direction of measuring device, strength characteristics, using stable tension/pressure to test material strength, etc. Physical output, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

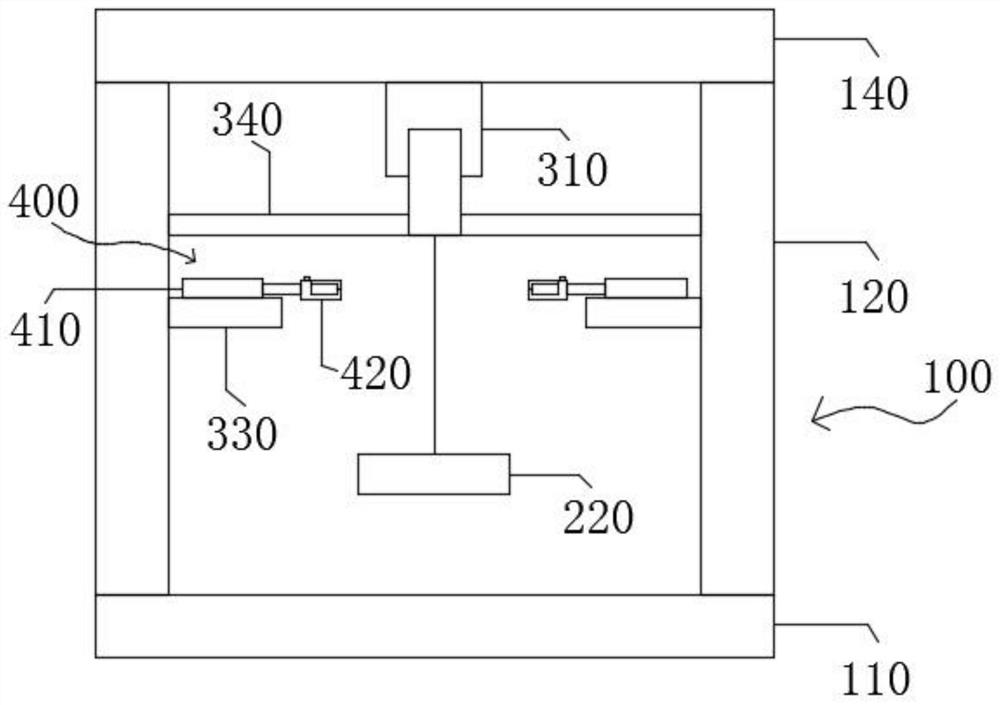

[0034] see Figure 1-Figure 4 , the application provides a chain link strength detection device for anchor chain production, including

[0035] Support mechanism 100, support mechanism 100 comprises base 110, support bar 120, two columns 130 and support plate 140, and the lower end of support bar 120 and column 130 is all welded and fixed on the base 110, and the upper end of support bar 120 and column 130 is all connected with The bottom of the support plate 140 is welded and fixed, and the side of the column 130 is provided with a guide groove 150;

[0036] The transfer mechanism 200, the transfer mechanism 200 includes an electric sliding table 210, an electromagnet 220 is fixedly connected to the sliding block of the electric sliding table 210, and the electric sliding table 210 is installed on the support plate 140 by bolts;

[0037] The lifting mechanism 300, the lifting mechanism 300 includes an electric cylinder 310, two guide blocks 320, a fixed plate 330 and a suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com