Remote control type magnetic drive hollow glass built-in shutter

A magnetic drive, remote control technology, used in windows/doors, door/window protection devices, buildings, etc., can solve problems such as laborious operation, increased cost of permanent magnets, and complex motor structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

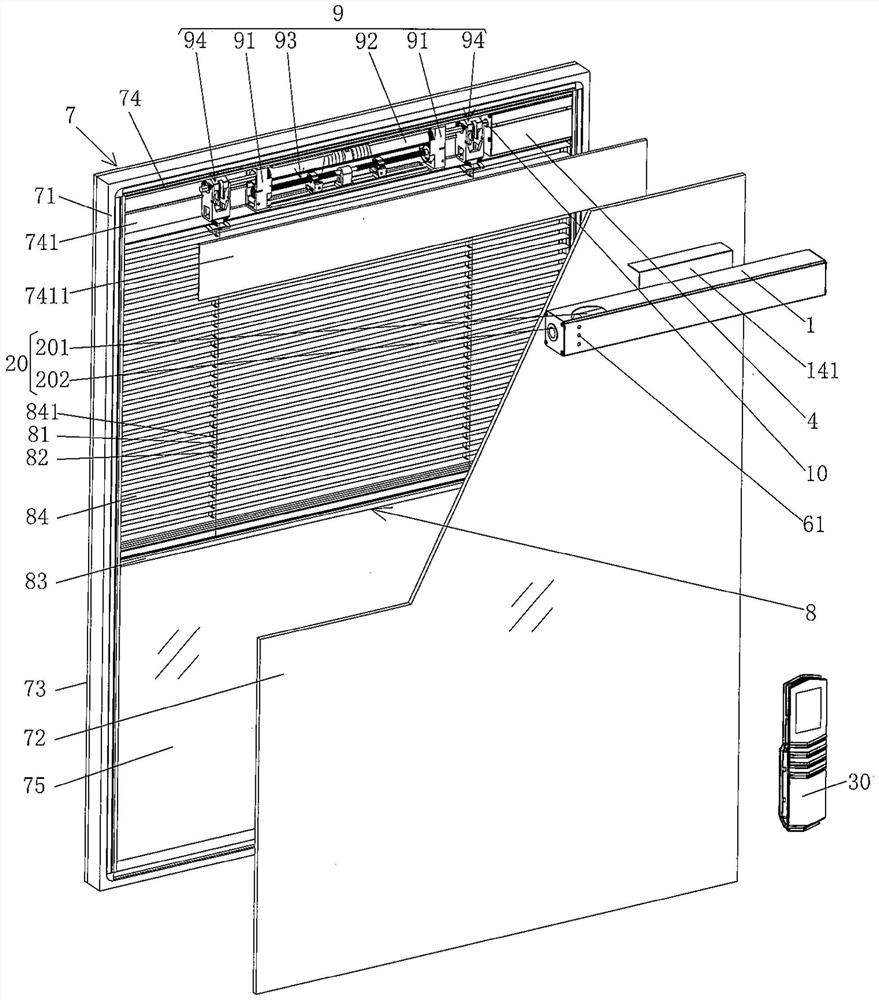

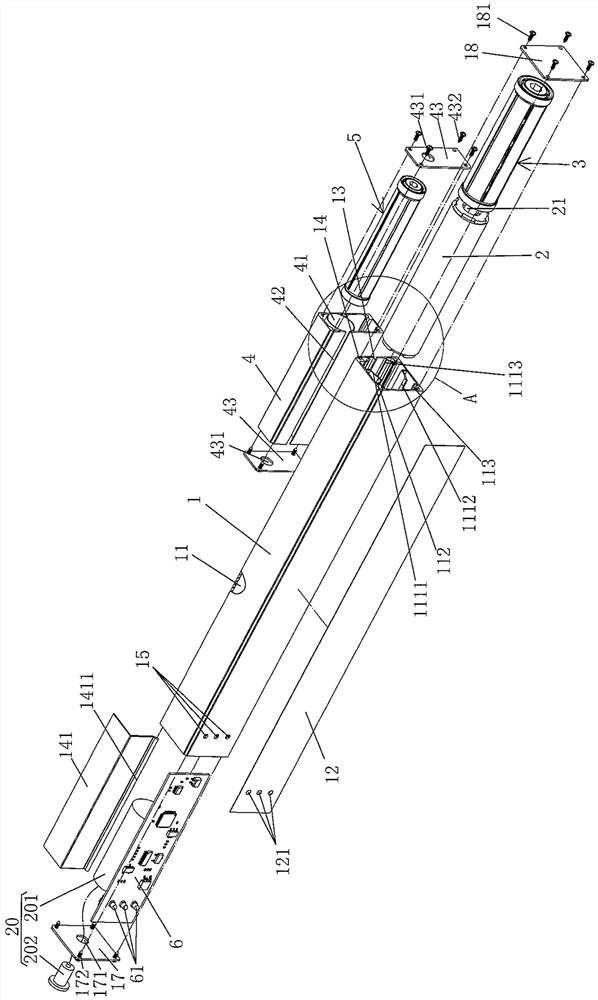

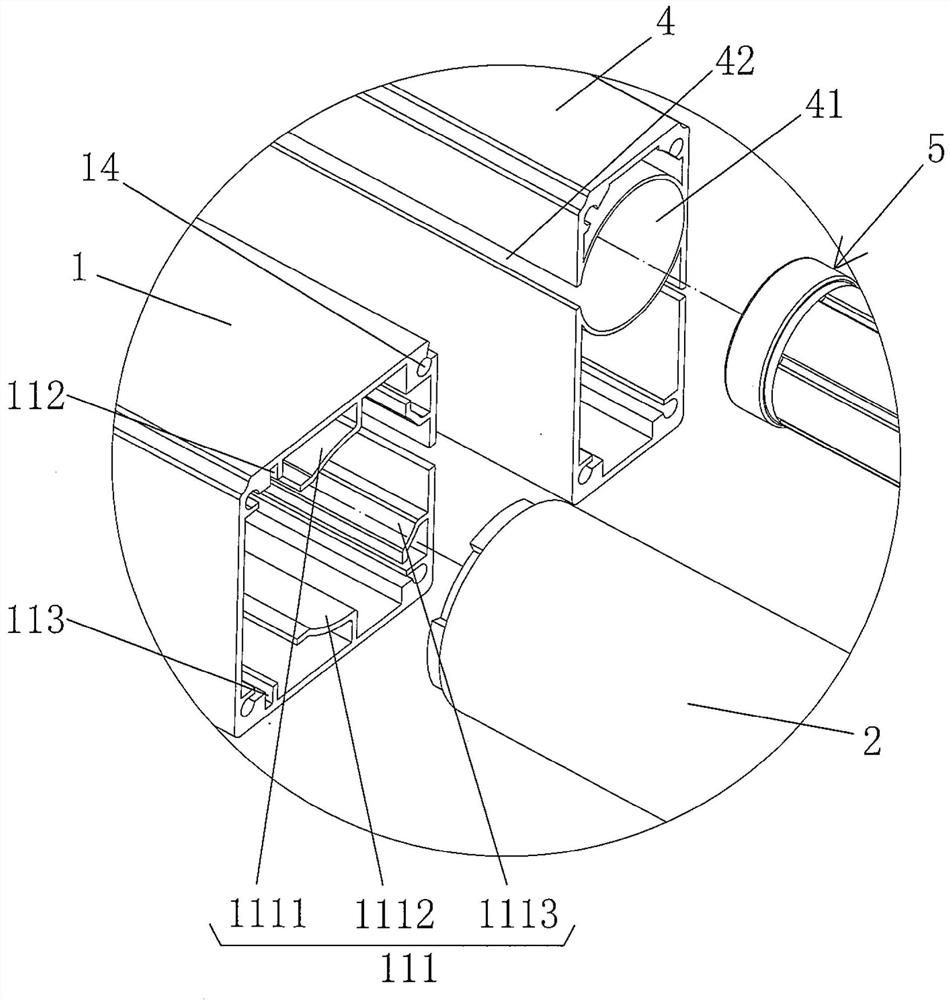

[0032] See figure 1 , shows a window 7, the window 7 includes a rectangular frame 71, an inner glass 72, an outer glass 73 and an upper horizontal frame bar 74, the inner glass 72 and the outer glass 73 are respectively arranged in a state facing each other At the front and rear sides (i.e. the front side and the rear side) of the rectangular frame body 71, the surrounding edges of the inner glass 72 and the outer glass 73 protrude from the outer side of the rectangular frame to form a rubber strip cavity, and the rubber strips are placed on the outer side of the rectangular frame. In the glue strip cavity, the peripheral edges of the opposite side of the inner glass 72 and the outer glass 73 are bonded and fixed together with the outer side surface of the rectangular frame body 71, between the inner glass 72 and the outer glass 73 and A venetian blind cavity 75 is formed corresponding to the hollow area surrounded by the rectangular frame body 71, and the upper horizontal fra...

Embodiment 2

[0076] See Figure 10 and combine figure 1 , in this embodiment, the structural system of the aforementioned power supply guarantee mechanism 20 adopts a storage battery 201 and a self-contained power supply mechanism 203. And it is arranged above the side of the aforementioned outer glass 73 facing the outside.

[0077]In this embodiment, the aforementioned independent power supply mechanism 203 includes a solar photovoltaic power generation device 2031 and a hanging board 2032, the solar photovoltaic power generation device 2031 is arranged on the hanging board 2032 and is formed by the hanging board 2032 together with the solar photovoltaic power generation device 2031 Hanging on the upper left side of the outer glass 73 facing the outside, the solar photovoltaic power generation device 2031 is introduced into the housing cavity 11 through the line 20311 through the charging socket matching hole 171 and electrically connected to the battery 201 . Since the solar photovolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com