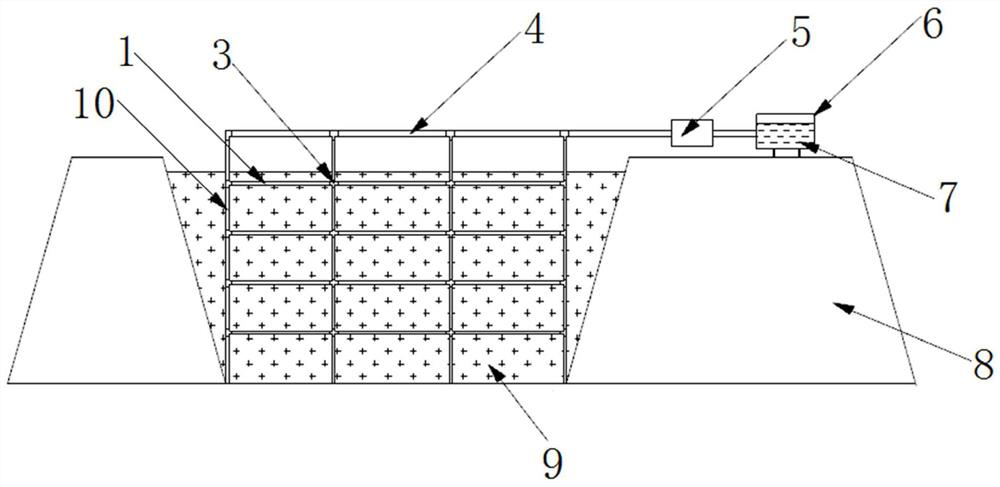

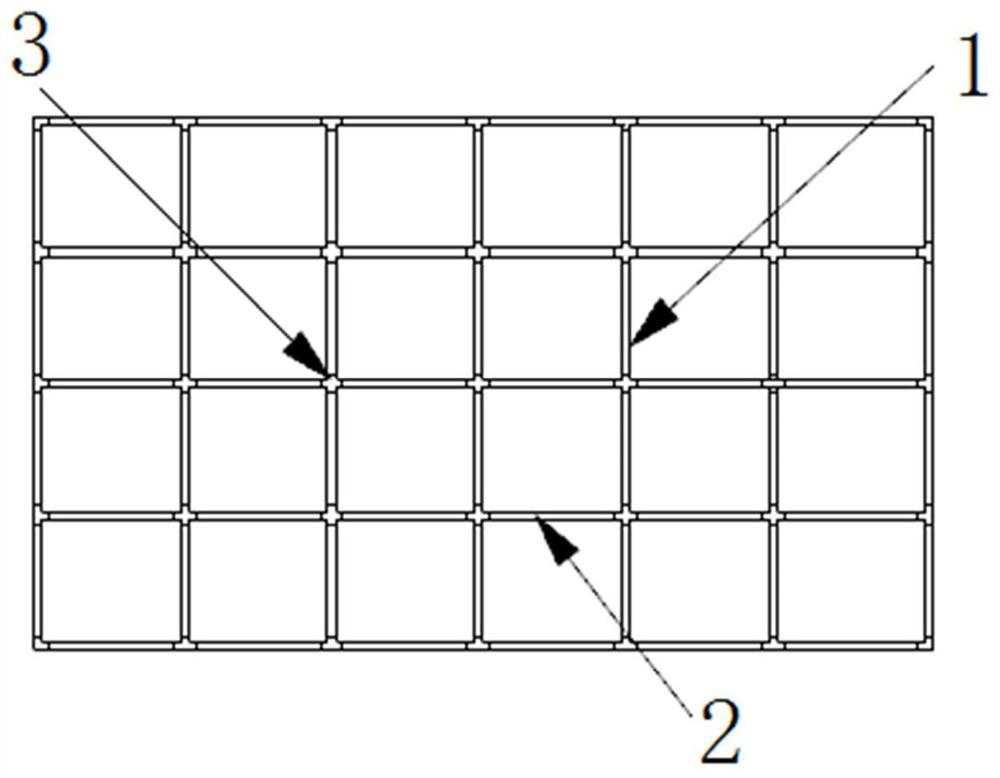

Liquefaction control method of blow filling sand based on straw degradation and microbial grouting and formed control structure

A technology of dredging sand and microorganisms, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of poor water retention performance, low and prominent organic matter content of dredged sand, and improve the ability of anti-liquefaction, sandy soil solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

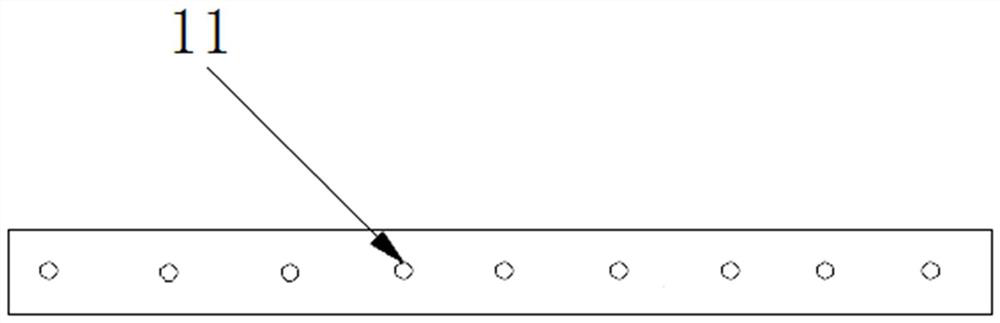

[0050] The dredger sand liquefaction control method based on straw degradation and microbial grouting provided by this application specifically includes the following steps:

[0051] In the first step, before the filling project is carried out, the waste straw is crushed to form broken straw, and the broken straw is soaked in the alkali solution for at least 24 hours; the straw itself has water absorption characteristics, and the water absorption performance of the broken straw after soaking in the alkali solution is improved. Greater enhancement, the enhanced water absorption can reduce the water content of the dredged sand and improve the internal anti-liquefaction ability; at the same time, the soaking treatment of the alkali solution destroys the structure of the broken straw, which can effectively improve the gas production efficiency of the straw during degradation , the alkaline solution can choose NaOH, Ca(OH) 2 Etc., during actual soaking operation, what this preferre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com