Lactic acid bacteria enrichment culture medium suitable for industrial production and production process thereof

A technology suitable for industrial production and enrichment culture medium, applied in the direction of microbial-based methods, using added compounds to stimulate growth, bacteria, etc., can solve the problems of high cost and increased feed production cost, and reduce production costs and reduce costs , The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

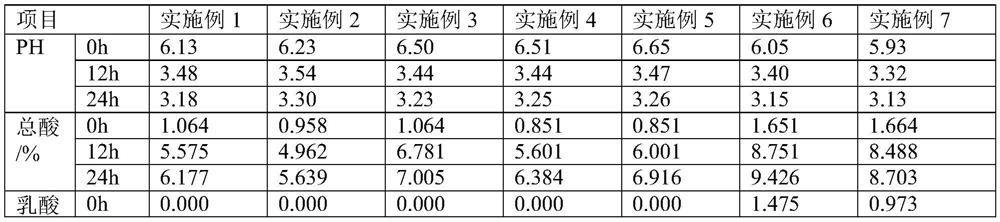

Examples

Embodiment 1

[0029] A kind of production technology of the lactic acid bacteria enrichment culture medium suitable for industrial production, comprises the steps:

[0030] (1) Add water to the activation tank, control the water temperature at 35±2°C, add 400g of glucose, 430g of soybean meal hydrolyzate, 19.8g of carrot powder, 15.2g of potato powder, 15g of vitamin C, 31.6g of dipotassium hydrogen phosphate, Potassium dihydrogen phosphate 43.4g, magnesium sulfate 4.8g, manganese sulfate 0.5g are mixed and stirred, and the aqueous solution that is mixed with weight concentration is 1.8%;

[0031] (2) Insert 900g of powdered compound lactic acid bacteria agent into the aqueous solution of step (1), activate it for more than 12 hours at a temperature of 35±2°C, and use it for more than 12 hours, wherein the compound lactic acid bacteria agent includes 10g of compound lactic acid bacteria and 890g of carrier , compound lactic acid bacteria include 0.8g of Lactobacillus plantarum, 1.8g of Lact...

Embodiment 2

[0034] A kind of production technology of the lactic acid bacteria enrichment culture medium suitable for industrial production, comprises the steps:

[0035] (1) Add water to the activation tank, control the water temperature at 35±2°C, add glucose 410g, soybean meal hydrolyzate 425g, carrot powder 21.5g, potato powder 16.5g, B vitamins 13g, dipotassium hydrogen phosphate 32.4 g, potassium dihydrogen phosphate 44.6g, magnesium sulfate 4.5g, manganese sulfate 0.6g are mixed and stirred, and are mixed with the aqueous solution that weight concentration is 1.8%;

[0036] (2) Insert 900g of powdered compound lactic acid bacteria agent into the aqueous solution of step (1), activate it for more than 12 hours at a temperature of 35±2°C; wherein the compound lactic acid bacteria agent includes 10g of compound lactic acid bacteria and 890g of carrier , compound lactic acid bacteria include 0.8g of Lactobacillus plantarum, 1.8g of Lactobacillus casei, 0.8g of Streptococcus thermophilu...

Embodiment 3

[0039] A kind of production technology of the lactic acid bacteria enrichment culture medium suitable for industrial production, comprises the steps:

[0040] (1) Add water to the activation tank, control the water temperature at 35±2°C, add 419g of glucose, 419g of soybean meal hydrolyzate, 25.2g of carrot powder, 16.8g of potato powder, 11g of B vitamins, and 42g of dipotassium hydrogen phosphate , Potassium dihydrogen phosphate 42g, magnesium sulfate 4.19g, manganese sulfate 1.05g are mixed and stirred, and the aqueous solution that is mixed with weight concentration is 2.0%;

[0041] (2) Insert 1000g of powdered compound lactic acid bacteria agent into the aqueous solution of step (1), activate it for more than 12 hours at a temperature of 35±2°C; wherein the compound lactic acid bacteria agent includes 10g of compound lactic acid bacteria and 990g of carrier , the compound lactic acid bacteria include 0.8g of Lactobacillus plantarum, 1.8g of Lactobacillus casei, 0.8g of S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com