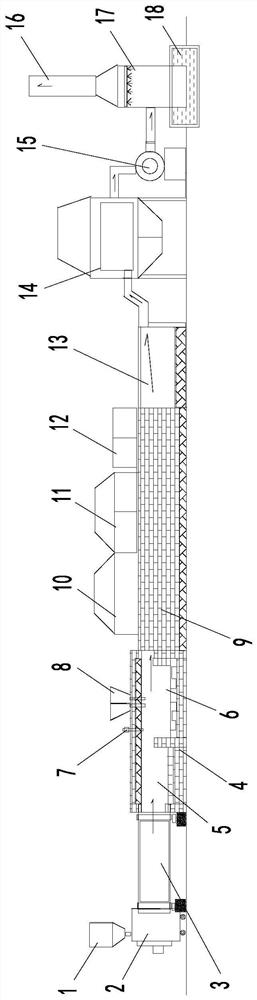

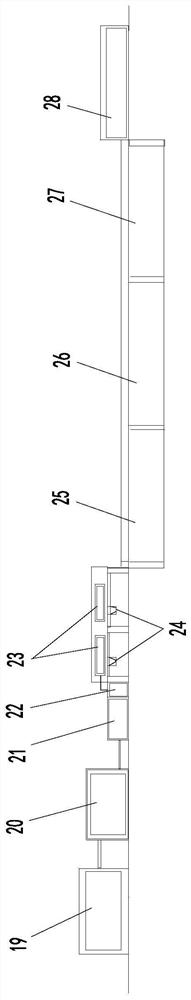

Kiln system for producing sodium sulfide by using industrial hazardous waste sodium sulfate and method thereof

A technology of hazardous waste sodium sulfate and sodium sulfide, which is applied in chemical instruments and methods, separation methods, alkali metal sulfides/polysulfides, etc., and can solve problems such as unstable product quality, low equipment operation rate, and high manufacturing costs. Achieve the effects of heat energy recovery, high operating rate and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

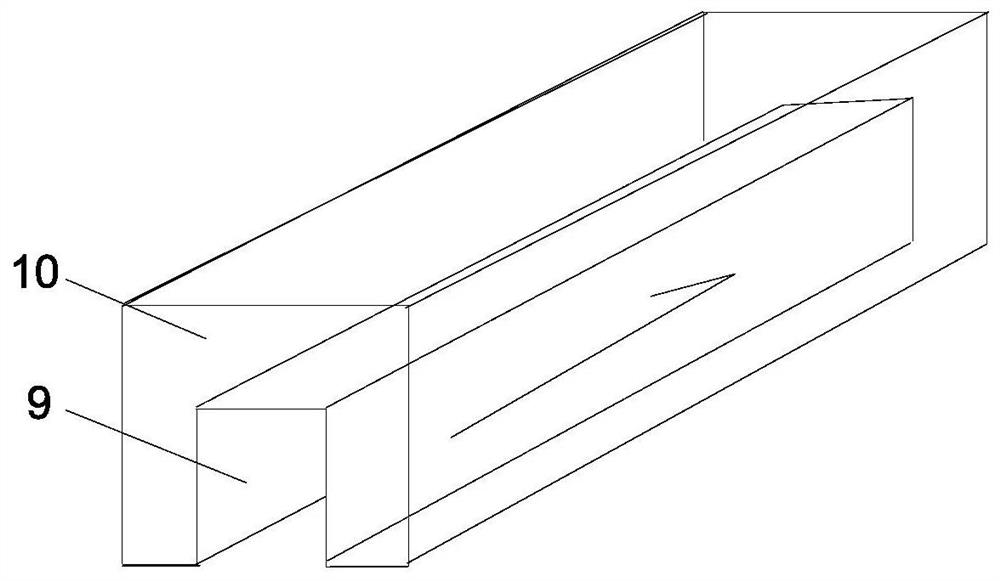

Method used

Image

Examples

Embodiment

[0070] After the kiln system of the present invention is built in the Panxi area, within one month of production, tracking, measurement, statistics and detection of each process have been carried out. The result is as follows:

[0071] 1) Main indicators of raw materials:

[0072] A. Solid waste sodium sulfate:

[0073] Na 2 SO 4 60-70%;H 2 O 28%; V 2 o 5 0.3%; other 1.7%;

[0074] B. Anthracite:

[0075] Fixed carbon ≥ 70%; Ash ≤ 18%; Volatile matter ≤ 10%; Water ≤ 2%;

[0076] C. Semi-coke, fixed carbon ≥ 80%; ash ≤ 10%; volatile matter ≤ 8%; water ≤ 1%;

[0077] D. Natural gas ≥ 9800 kcal / m 3 ;

[0078] 2) According to the product volume of 200 tons, the average consumption per ton is calculated:

[0079] A solid waste sodium sulfate 2.1 tons / t consumption;

[0080] B Anthracite 0.3 tons / t consumption;

[0081] C semi-coke 0.1 ton / t consumption;

[0082] D natural gas 280m 3 / t consumption;

[0083] E power consumption 110 degrees / t consumption;

[0084]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com