A waste transfer system waste bucket jacking mechanism

A technology of jacking mechanism and waste bin, which is applied in the direction of lifting frame, lifting device, reducing greenhouse gas, etc. It can solve the problems of shielding barrel lid falling off, waste bin being inconvenient to pick and place, waste bin without protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

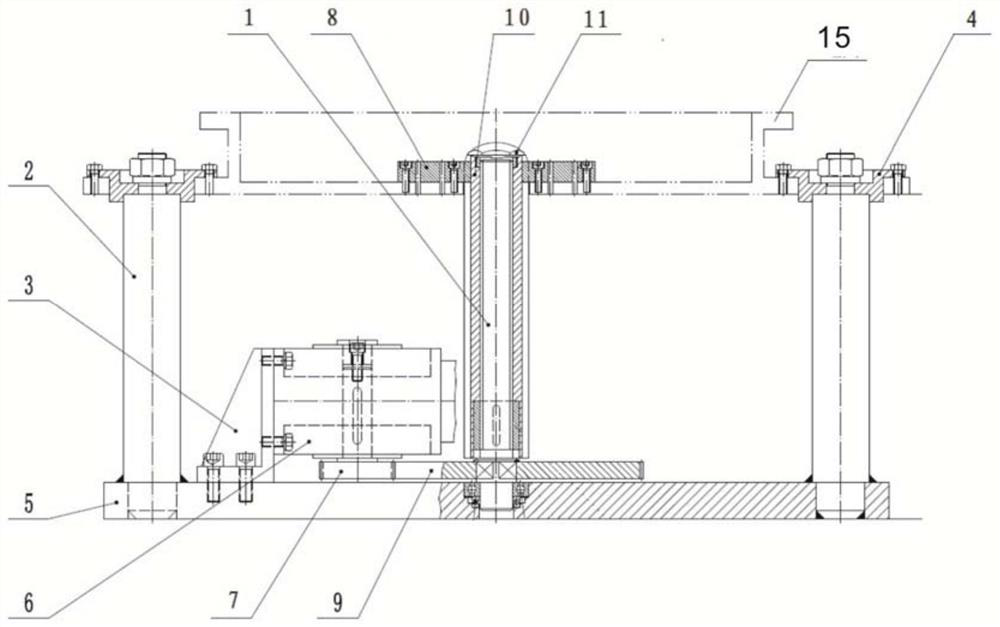

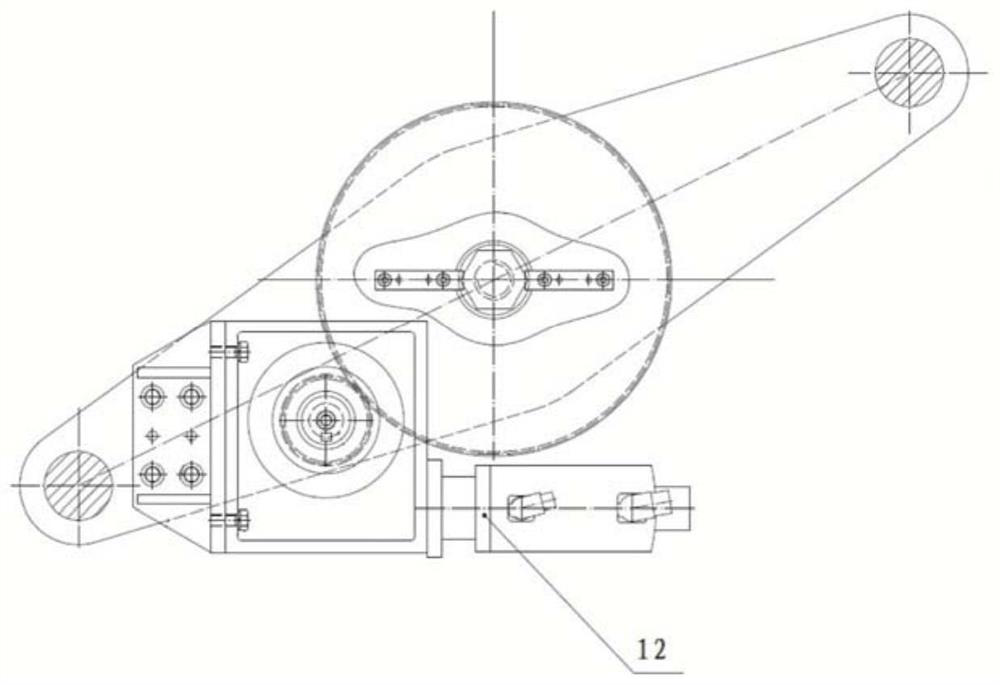

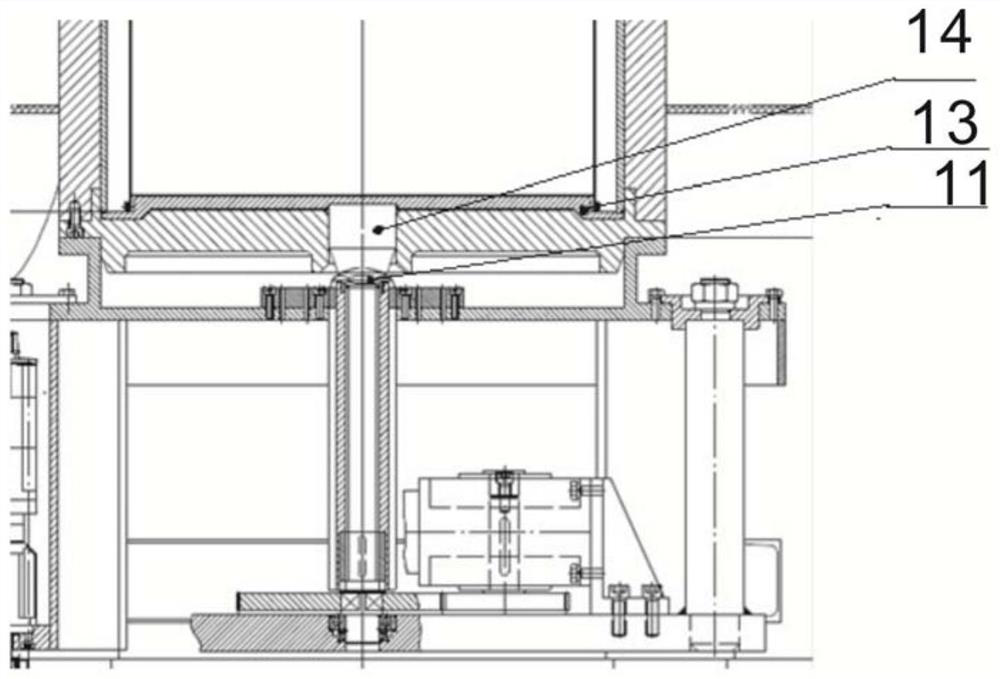

[0024] like figure 1 and figure 2 As shown, the present invention discloses a waste bucket jacking mechanism of a waste transfer system, including a load-bearing support 15, a jacking support, a driving mechanism, a jacking mechanism and an annular bracket 13 (see image 3 ); the jacking mechanism and the load-bearing support 15 are both installed on the jacking support; the drive mechanism drives the jack 10 of the jacking mechanism to move so that the jack 10 is placed on the load-bearing The annular bracket 13 on the support 15 mates. The driving mechanism includes a motor assembly 12 and a reducer assembly; in this embodiment, a motor bracket 3 is provided on the jacking support, and the worm gear reducer 6 is installed on the motor bracket 3 .

[0025] The jacking mechanism includes a gear 9, a screw 1 and a jack 10; the jack 10 is threaded wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com