Film laminating machine for plate

A technology of laminating machine and laminating mechanism, applied in the field of laminating machine, can solve problems such as film aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

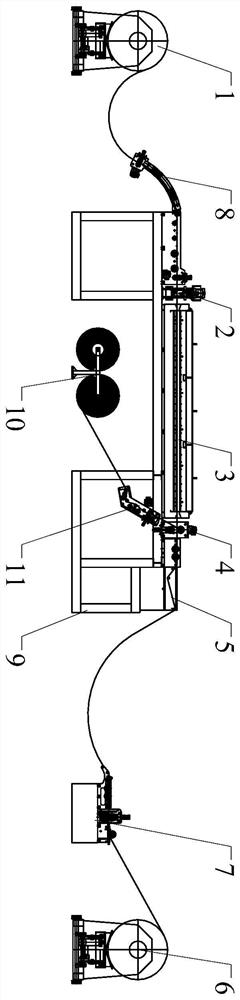

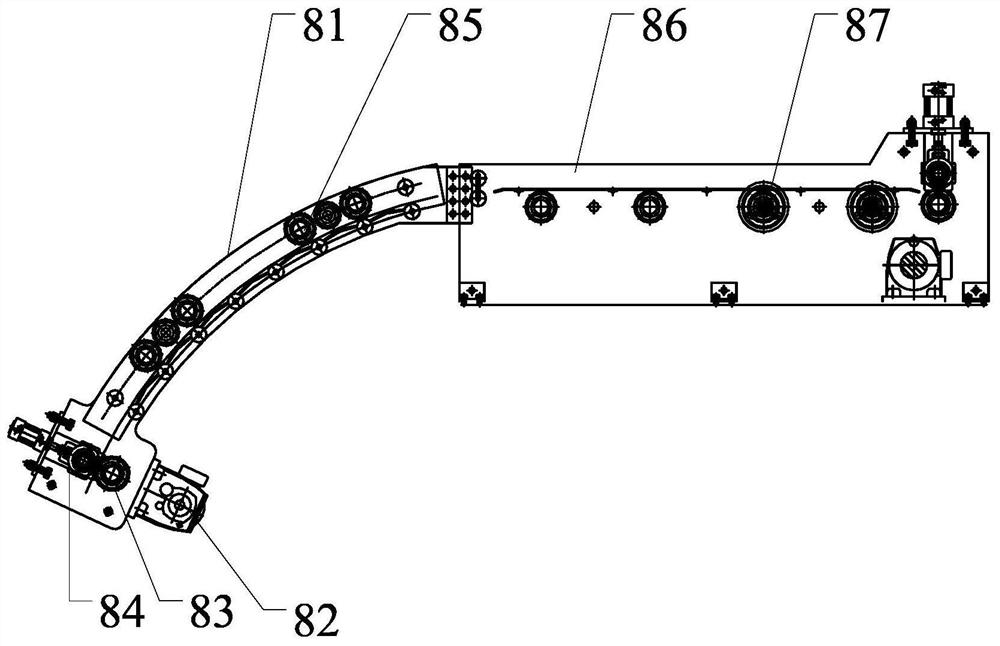

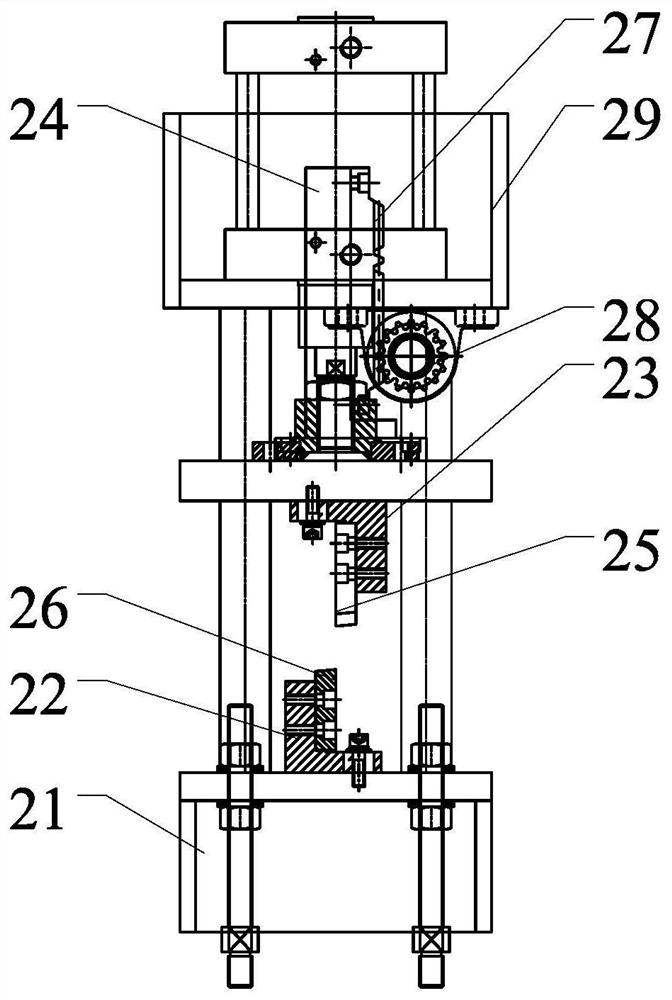

[0027] figure 1 It is a structural schematic diagram of an embodiment of a plate laminating machine of the present invention. As shown in the figure, the present invention provides a plate laminating machine, including an uncoiler 1, a pneumatic shearing mechanism 2 arranged at the rear end of the uncoiler 1, and a pneumatic shearing mechanism 2 arranged at the rear end of the uncoiler 1. The constant temperature heating box 3 at the rear end of the shearing mechanism 2, the coating mechanism 4 arranged at the rear end of the constant temperature heating box 3, the circulating water cooling mechanism 5 arranged at the rear end of the coating mechanism 4 and the winder arranged at the rear end of the circulating water cooling mechanism 5 6. A tension mechanism 7 is set between the winding machine 6 and the circulating water cooling mechanism 5; a first guiding feeding mechanism 8 is set between the pneumatic shearing mechanism 2 and the uncoiler 1, the first guiding feeding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com